- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V-460V

-

Power:

-

32kw

-

Dimension(L*W*H):

-

4.8*2.2*2.2m

-

Weight:

-

7000 KG

-

Machinery Function:

-

280kg/h

-

Output product name:

-

Freeze-dried Food

-

Type:

-

freeze drying equipment

-

Application:

-

Food Industry

-

Name:

-

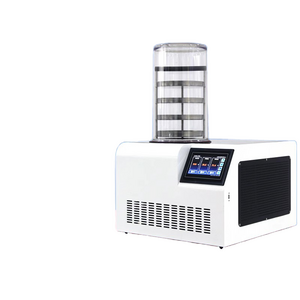

freeze dryer

-

Product name:

-

freeze-dried food

-

After-sales Service Provided:

-

Overseas

-

Usage:

-

Commercial Usage

-

Material:

-

Stainless Steel 304/316L

-

Capacity:

-

280kg/h

-

Advantage:

-

High Effieciency

-

Keywords:

-

freeze dryer

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Brand Name:

-

Xinyang

-

Place of Origin:

-

Liaoning, China

-

Voltage:

-

380V-460V

-

Power:

-

32kw

-

Dimension(L*W*H):

-

4.8*2.2*2.2m

-

Weight:

-

7000 KG

-

Machinery Function:

-

280kg/h

-

Output product name:

-

Freeze-dried Food

-

Type:

-

freeze drying equipment

-

Application:

-

Food Industry

-

Name:

-

freeze dryer

-

Product name:

-

freeze-dried food

-

After-sales Service Provided:

-

Overseas

-

Usage:

-

Commercial Usage

-

Material:

-

Stainless Steel 304/316L

-

Capacity:

-

280kg/h

-

Advantage:

-

High Effieciency

-

Keywords:

-

freeze dryer

What is Freeze dryer ?

Freeze-drying—technically known as lyophilisation, lyophilization, or cryodesiccation—is a dehydration process typically used to preserve a perishable material or make the material more convenient for transport. Freeze-drying works byfreezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimedirectly from the solid phase to the gas phase.

Vacuum freeze drying technology is the most advanced technology for food dehydration processing at present. Compared with the common drying method, the freeze-dried food produced with this technology features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste, shape and high content of nutritious components. The dried food basically remains unchanged in its volume and shape, it looks like sponge and has no shrinking. This kind drying technology can be widely used in process of vegetables, fruits, condiments, aquatic products, biological products, medicine, beverage and etc.

Advantages of Freeze Dried Food

1. Taste fresh.

Freeze-dried foods, like frozen, retain virtually all their fresh-food taste and nutritional content. Freeze-drying removes the water, not the flavor.

2. Look fresh.

Freeze-dried foods maintain their original shape and texture, unlike dehydrated foods, which shrink and shrivel due to high-temperature processing. Freeze-drying removes water under low temperatures which keeps intact the moisture channels and food fibers. Just add water, and in minutes every fresh food detail returns.

3. Weigh less than fresh.

Freeze-dried foods have 98% of their water removed. This reduces the food's weight by about 90%. Because of its light weight per volume of reconstituted food, freeze-dried products are popular and convenient for hikers. More dried food can be carried per the same weight of wet food, and remains in good condition for longer than wet food, which tends to spoil quickly. Hikers reconstitute the food with water available at point of use.

4. Stay fresh.

Freeze-dried foods can be stored at room temperature, without deterioration or spoilage. This is because freeze-drying and packaging remove both water and oxygen - the two primary causes of food deterioration.

5. Regain freshness quickly.

Freeze-dried products can be rehydrated (reconstituted) much more quickly and easily because the freeze drying process leaves microscopic pores. The pores are created by the ice crystals that sublimate, leaving gaps or pores in their place.

6. Long-Term Storage.

The freeze dried product in sealed packaging can be stored and transported at room temperature for a long time. Freeze-drying increase the shelf life of product for years.

Working Princple of Freeze Drying Machine

Under vacuum condition, material is freeze dried via principle of sublimation. The moisture in the pre-frozen material is directly sublimed from solid state (ice) to gaseous state (vapor), without melting. Freeze dried products are formed to be sponginess, without shrinkage and excellent in rehydration, containing little water only.

Advantages of Our Freeze Drying Equipment

1. Efficient in heating plates.

The material of heating plates is aviation aluminum after being anodized on the surface, releasing over 100% heat from the product by radiation. This makes heat more uniform and complete.

2. Alternate vapor trap.

Double trap is installed under the heating plates in drying chamber. Trap 1 condenses vapor to its maximum cpacity, then trap 2 starts to work. In the meantime, trap 1 begins to melt ice for another condensation cycle.

3. Continous de-icing.

When the trap 2 begins to catch vapor, the trap 1 begins to melt ice on the coil during drying. After melting, the clean coil is ready for another condensation cycle.

4. Automatic control system.

Advanced intelligent control system keeps the system running stably and reliably in a long time. Furthermore, simple operation can be much easier to handle.

|

Specification Model

|

LG0.2

|

LG1.0

|

LG1.5

|

LG5

|

LG10

|

LG20

|

|

||||||

|

Heating Areas(m2)

|

0.2

|

0.8

|

1.5

|

5.3

|

10

|

20

|

|

||||||

|

Numbers of Vapor trap

|

Single

|

Single

|

Single

|

Single

|

Single

|

Single

|

Double

|

||||||

|

Trapping Capacity(batch)

|

>2kg

|

>8kg

|

>20kg

|

>65kg

|

>130kg

|

>250kg

|

>44kg/hr

|

||||||

|

Heating Medium

|

Electric

|

|

|

Water&electric

|

|

|

Water&Steam

|

||||||

|

Heating Mode

|

Double side radiation

|

|

|

|

|

|

|

||||||

|

Temperature range of Heating plates

|

Normal Temp.~+120℃

|

|

|

<95℃

|

<95℃

|

<95℃

|

Normal Temp.~+130℃

|

||||||

|

Vacuum Pressure (Pa)

|

20~133

|

|

|

|

|

|

|

||||||

|

Need Refrigeration Capacity (t0=-40℃,tk=-35℃) (Kw)

|

With Refrigeration System

|

|

|

|

18

|

35

|

44

|

||||||

|

Consumption of Steam (kg/h)

|

None

|

None

|

None

|

None

|

50

|

None

|

75

|

||||||

|

Electric Power Supply (Kw)

|

3.2

|

8.5

|

15

|

35

|

26

|

65

|

38

|

||||||

|

Tray Numbers

|

2

|

4

|

4

|

14

|

26

|

52

|

54

|

||||||

|

Loading Raw Material(KG)

|

3

|

8

|

20

|

>70

|

>130

|

>260

|

>270

|

||||||

Xinyang Company closely cooperated with Atlas Company in Denmark, Harbin Commerce University, Zhejiang University and Northeastern University, etc., our team have supported over 1,500 food engineering projects both domestically and abroad, our products have been exported to USA, Canada, Germany, Netherland, Singapore, Thailand, Malaysia, Indonesia, Korea, Myanmar, Chile, Nigeria etc.

A: Freeze-drying—technically known as lyophilisation, lyophilization, or cryodesiccation—is a dehydration process typically used to preserve a perishable material or make the material more convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublime directly from the solid phase to the gas phase.

Q: How many properties of freeze-dried products?

A: If a freeze-dried substance is sealed to prevent the reabsorption of moisture, the substance may be stored at room temperature without refrigeration, and be protected against spoilage for many years. Preservation is possible because the greatly reduced water content inhibits the action of microorganisms and enzymes that would normally spoil or degrade the substance.

Freeze-drying also causes less damage to the substance than other dehydration methods using higher temperatures. Freeze-drying does not usually cause shrinkage or toughening of the material being dried. In addition, flavours, smells and nutritional content generally remain unchanged, making the process popular for preserving food. However, water is not the only chemical capable of sublimation, and the loss of other volatile compounds such as acetic acid (vinegar) and alcohols can yield undesirable results.

Q: Why freeze dried food is so popular?

A: Freeze-drying is a scientific art, combining science and controlled process to result in beautifully preserved food. It retains the most nutrients than any other food preservation method, and maintains its color and flavor. Freeze-drying is also one of the safest methods of food handling used today.

In the food service environment, freeze-dried products require no further handling. They’re ready to eat or be incorporated into products and recipes. In contrast, frozen foods may need to be thawed, then cut, sliced, or diced. Proper thawing measures can stave off pathogen multipliers, but bacteria flourish at room temperature.

Freeze-dried food can help you deliver clean ingredients to consumers. Not only are freeze-dried products easy and versatile, they have a long shelf life and add unique flavor and texture to your new or existing products.

Q: Why is it right to choose our freeze-drying equipment?

A: Because our freeze-drying equipment has higher efficiency, low failure rate, low energy consumption and high degree of automation.

1. Our freeze-drying equipment does not need extra water to melt ice with its own water.

2. The melting ice of our freeze-drying equipment takes place under vacuum conditions, in the process of operation of the frozen dry equipment, automatically melting ice;

3. We do not need heat preservation, drying tank in the whole freeze-drying process, the outer surface of the hull just at room temperature, we will all focus on material, heat so as to reduce the energy consumption.

4. Our equipment does not need maintenance, and the quality of the equipment represents our service purpose, and we pay more attention to the interests of customers.