- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2021

-

specifications:

-

50 type

-

Maximum outside diamete:

-

50

-

Molding time:

-

7-30s/time

-

Maximum machining length:

-

100mm

-

Spindle motor:

-

4.0kw

-

Machined tube wall thickness:

-

0.5-2.0mm

-

Name:

-

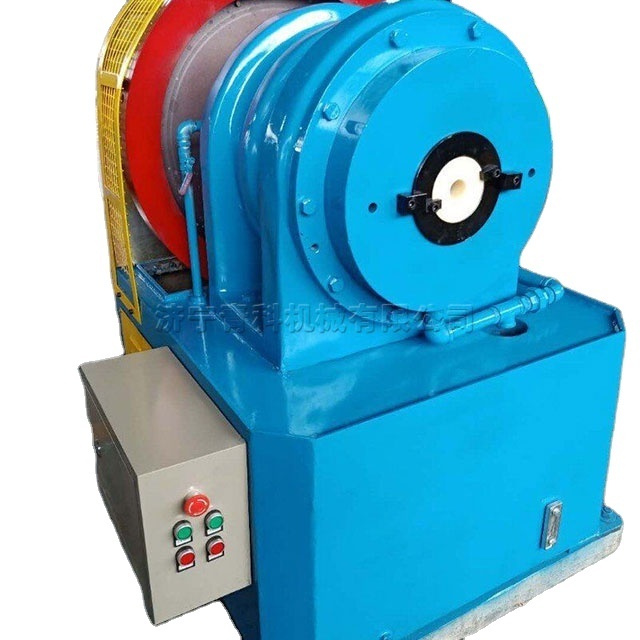

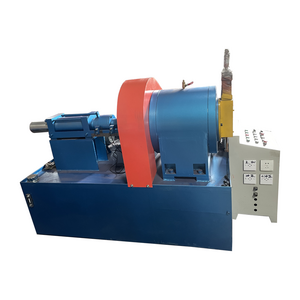

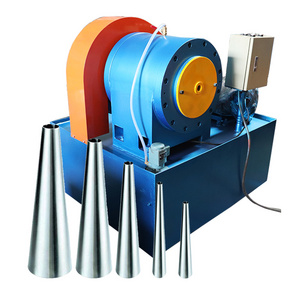

Tapered pipe shrinking machine

-

Weight:

-

600kg

-

Color:

-

Blue

-

Efficiency:

-

3000-5000/day

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

qk

-

Weight (KG):

-

600

-

Marketing Type:

-

New Product 2021

-

specifications:

-

50 type

-

Maximum outside diamete:

-

50

-

Molding time:

-

7-30s/time

-

Maximum machining length:

-

100mm

-

Spindle motor:

-

4.0kw

-

Machined tube wall thickness:

-

0.5-2.0mm

-

Name:

-

Tapered pipe shrinking machine

-

Weight:

-

600kg

-

Color:

-

Blue

-

Efficiency:

-

3000-5000/day

Tube Tapering Machine Manual Iron Pipe Reducing Machine with Reasonable Price

Tube shrinking machine is used for processing metal tube, conical tube, manual and automatic choice, with low noise, easy to operate. High output, stable performance and other characteristics, workpiece forming time is short, high efficiency, smooth processing surface, workpiece without scars. The machine is easy to replace and can process metal pipes of different shapes to meet different requirements. Suitable for automobile, furniture lighting, bicycle, grouting small pipe taper molding.

|

specifications |

50 type |

specifications |

50 heavy-duty |

|

Maximum outside diameter of shrinkage tube |

50 |

Maximum outside diameter of shrinkage tube |

50 |

|

Molding time |

7-30s/time |

Molding time |

7-30s/time |

|

Maximum machining length |

100mm |

Maximum machining length |

300mm |

|

Spindle motor |

4.0kw |

Spindle motor |

4.0kw |

|

Machined tube wall thickness |

0.5-2.0mm |

Machined tube wall thickness |

0.5-2.0mm |

Are you manufacture?

Yes. We are one of leading manufacturers

Do you have Stock productions to sell?

Yes,of course.But we also offer OEM service. Please send us some drawing.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual for punctual delivery.

(2) 20year s production experience. We have over 20 years exp erience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to discuss with him for all the problems and the way sames much times .

Pre-sale Service

1.Supply item design,process design.

2.Help you to chose the fit machine.

3.Making the machine according to your requirement.

Sale Service

1.Acceptance equipment together with you.

2.Help you to make the method statement and the details of the process.

After Service

1.Guarantee for a year.

2.Quality problem,we will send you the accessories.

3.Free repair whole using life(without the freight and accessories charge).

Wooden cased Carton case As custom's require