- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

Lillte

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

Unknow

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Customer's Requirement

-

Brand Name:

-

RongSheng

-

Product name:

-

High Alumina Refractory Brick

-

Color:

-

Yellow

-

Feature:

-

Thermal Shock Resistance

-

Porosity(%):

-

<22

-

Linear Change on:

-

+0.1-0.4

-

Size:

-

Customizable

-

keyword:

-

high aluminium fire bricks for kilns

-

Usage:

-

Furnace Liner

-

Certificate:

-

ISO9001, CE

Quick Details

-

SiO2 Content (%):

-

0.1Max

-

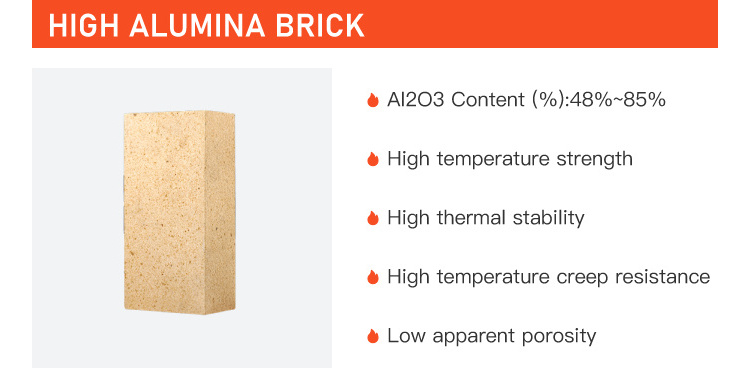

Al2O3 Content (%):

-

42~65%

-

MgO Content (%):

-

0

-

CaO Content (%):

-

Lillte

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

Unknow

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Customer's Requirement

-

Brand Name:

-

RongSheng

-

Product name:

-

High Alumina Refractory Brick

-

Color:

-

Yellow

-

Feature:

-

Thermal Shock Resistance

-

Porosity(%):

-

<22

-

Linear Change on:

-

+0.1-0.4

-

Size:

-

Customizable

-

keyword:

-

high aluminium fire bricks for kilns

-

Usage:

-

Furnace Liner

-

Certificate:

-

ISO9001, CE

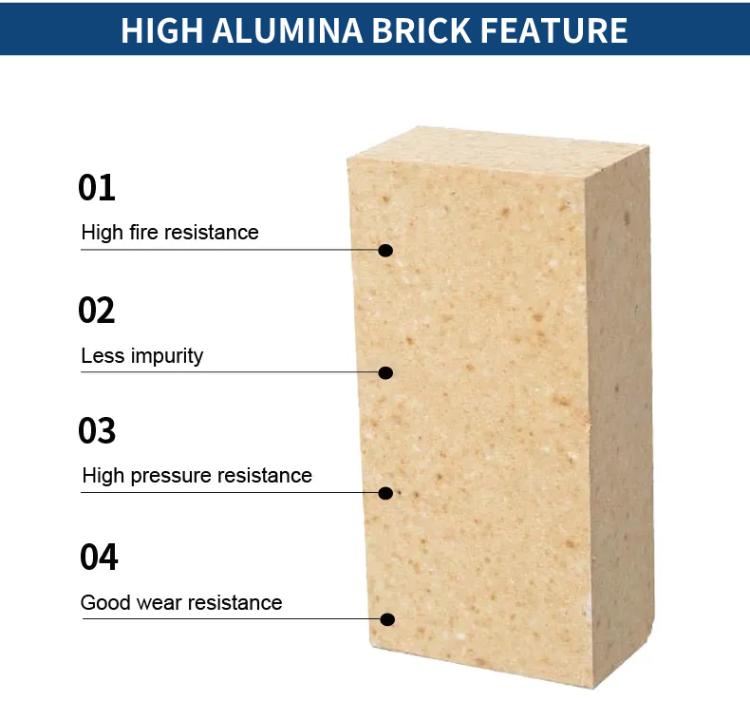

High Alumina Refractory Bricks Introduction

High alumina brick is a kind of neutral refractory with alumina content above 48%. It is formed by shaping and calcining bauxite or other raw materials with high alumina content. High thermal stability and fire resistance above 1770 ℃. The production process of high alumina bricks is similar to that of multi clinker clay bricks. The difference is that the proportion of clinker in the ingredients is high, up to 90~95%. Before crushing, the clinker needs to be sorted and screened to remove iron. The firing temperature is high. For example, when high alumina bricks such as I and II are fired in tunnel kilns, it is generally 1500~1600 ℃. Raw Materials of High Alumina Bricks

According to the different resource situation and production requirement, adopt below several raw materials: high-alumina bauxite, sillimanite mineral and synthetic raw materials. There are abundant resources of high-alumina bauxite with fine quality in China.RS Company purchases raw materials only from our trusted suppliers that we have cooperated with for long term. All the raw materials shall be checked strictly upon they reached the factory. Each production process will be controlled strictly to ensure the quality and consistency so that providing customers with the best quality high alumina bricks.

|

Item

|

Specification

|

|

|

|

|

|

|||||

|

|

LZ-80

|

LZ-75

|

LZ-70

|

LZ-65

|

LZ-55

|

LZ-48

|

|||||

|

Al2O3 %

|

≥80

|

≥75

|

≥70

|

≥65

|

≥55

|

≥48

|

|||||

|

Apparent Porosity, %

|

≤21

|

≤24

|

≤24

|

≤24

|

≤22

|

≤22

|

|||||

|

CCS, MPa

|

≥70

|

≥60

|

≥55

|

≥50

|

≥45

|

≥40

|

|||||

|

0.2MPa RUL ℃

|

≥1530

|

≥1520

|

≥1510

|

≥1500

|

≥1450

|

≥1420

|

|||||

|

PLC, %

|

1500℃×2h

-0.4~0.2 |

|

1450℃×2h

-0.4~0.1 |

|

|

|

|||||

ZHENGZHOU RONGSHENG REFRACTORY CO., LIMITED

has 30 years of experience in R & D and design of unshape refractory experts, holds 20 utility model patents and 7 invention patents, and has passed the ISO quality, environment and safety management system certification. The company is committed to the R & D, production and service of refractories used in metallurgy, electric power, nonferrous metals, building materials, chemical industry and other industries. Its products cover 198 kinds of materials and 2369 varieties in three categories (acidic, neutral and alkaline), providing overall solutions for refractories for 1200 domestic and 200 foreign customers.