- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

1-20pec/min(Determined by product size )

-

Weight (KG):

-

280

-

Voltage:

-

380V/50Hz/3phase

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Deman

-

Dimension(L*W*H):

-

1720*1820*1200mm

-

Product name:

-

Vacuum Packaging Machinery

-

sealing strip length:

-

1000mm

-

max packing bag length:

-

440mm

-

max packing bag height:

-

90-100mm

-

Pumping speed:

-

202m³/h

-

Material:

-

Stainless Steel

-

Chamber type:

-

continuous

-

Keyword:

-

Vacum Food Packs

Quick Details

-

Function:

-

Sealing, Packing

-

Packaging Type:

-

Stand-up Pouch, Bags, Film, Foil, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

1-20pec/min(Determined by product size )

-

Weight (KG):

-

280

-

Voltage:

-

380V/50Hz/3phase

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Deman

-

Dimension(L*W*H):

-

1720*1820*1200mm

-

Product name:

-

Vacuum Packaging Machinery

-

sealing strip length:

-

1000mm

-

max packing bag length:

-

440mm

-

max packing bag height:

-

90-100mm

-

Pumping speed:

-

202m³/h

-

Material:

-

Stainless Steel

-

Chamber type:

-

continuous

-

Keyword:

-

Vacum Food Packs

factory price vacuum Delicatessen packing machine sausage Salami vacuum packaging machine dried beef Biltong packer machine

Introduction of vacuum packaging machine

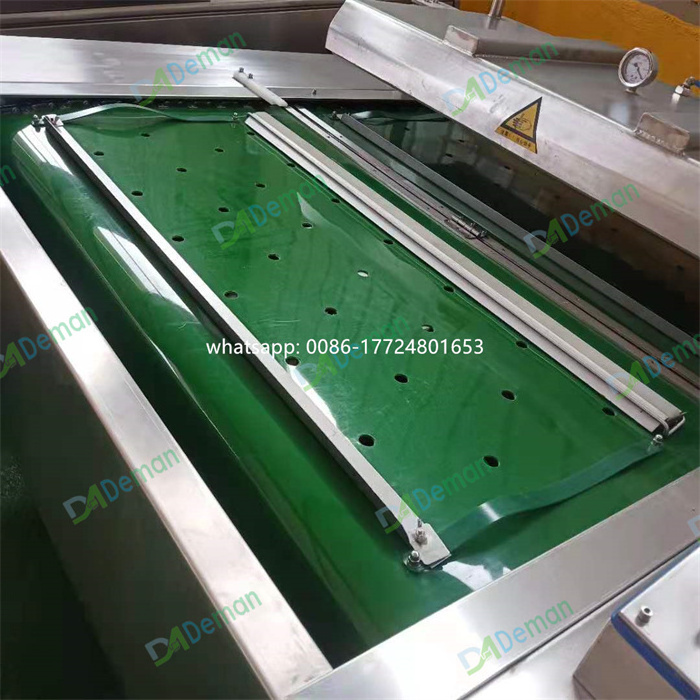

1. The sealing size of the rolling vacuum packaging machine is 1000mm, which is especially suitable for products with large packaging sizes.

The entire vacuum chamber is large, and the working process is fully automatic and continuous conveying products.

The working efficiency is high and can meet the requirements of high output.

2. The opening and closing of the upper cover of the vacuum chamber of the rolling vacuum packaging machine is automatically

completed by the transmission system of the equipment, which saves the manual work of opening and closing the cover manually,

which can not only reduce the labor intensity of the operator,

but also make the opening and closing time constant, which can Improve work efficiency.

3. The rolling vacuum packaging machine has the advantages of stable lifting and accurate positioning of the rolling belt;

the equipment operator does not need to manually adjust the position of the conveyor belt, which saves time and effort.

4. The hardware configuration of the rolling vacuum packaging machine is extremely high.

The vacuum pump adopts German Puxu environmental protection high vacuum environmental protection vacuum pump,

the operation panel adopts waterproof microcomputer control panel, and the conveyor belt adopts the conveyor belt imported from the Netherlands.

The whole machine is reliable in quality and stable in performance.

5. The overall structure of the rolling vacuum packaging machine is made of 304 stainless steel,

which can ensure the durable use of the machine in various working environments and improve the service life of the equipment.

Technical Parameter

| model | DM-LXS-1000 |

| voltage | 380V 50hz 3phase |

| power | 4.5kw |

| ultimate vacuum | ≤200PA |

| Vacuum efficiency | 202m³/h |

| packing speed | 3-5times/min |

| sealing strip number | 1 |

| sealing strip length | 1000mm |

| max packing bag length | 440mm |

| max packing bag height | 90-100mm |

| overall dimension | 1720*1820*1200mm |

Product Details

Real-shot Show

Your machine will be delivered by sea, air or express according to your needs.Before packaging, the goods are first wrapped with protective film to prevent scratches and corrosion, and then placed in wooden boxes for shipment.