- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YEKETECH

-

Product name:

-

Bottle Cap Defects Inspection Equipment

-

Feature:

-

High Precision

-

Speed:

-

300pcs/m

-

Function:

-

inspect defect

-

Precision:

-

0.1mm

-

Accuracy:

-

99.5%

-

Size:

-

3700*1300*1785mm

-

Weight:

-

350kg

-

Material:

-

Stainless Steel 304

Quick Details

-

Warranty:

-

3 years

-

Power:

-

5000-7000W

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

YEKETECH

-

Product name:

-

Bottle Cap Defects Inspection Equipment

-

Feature:

-

High Precision

-

Speed:

-

300pcs/m

-

Function:

-

inspect defect

-

Precision:

-

0.1mm

-

Accuracy:

-

99.5%

-

Size:

-

3700*1300*1785mm

-

Weight:

-

350kg

-

Material:

-

Stainless Steel 304

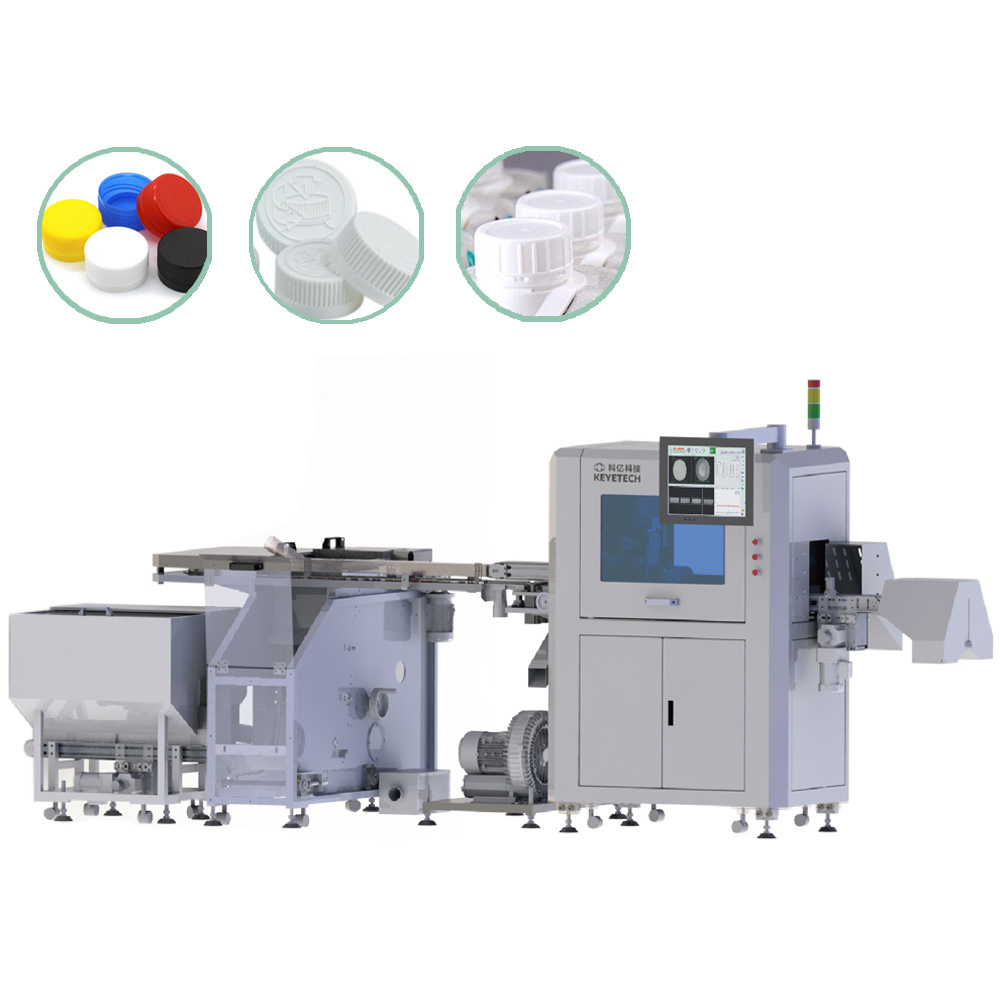

Product Overview

KEYETECH Bottle Cap Defects Inspection Equipment with Computer Vision for High Quality Control

Main Features:

-

High definition industrial camera &lens

-

High brightness strobe light source

-

Deep learning AI algorithm platform

-

High efficiency GPU processing platform

-

High resolution industry touch screen

Main Specifications:

|

Inspection range

|

Black spots, color difference, impurities, thread, rings, gap, flash, bubbles, deformation...

|

|

Inspection position

|

Cap concave, top, sidewall

|

|

Inspection speed

|

Customized (from 150pcs/min~2500pcs/min)

|

|

Inspection accuracy

|

99.5% (guaranteed)

|

|

Inspection precision

|

0.1mm

|

|

Air pressure

|

0.5Mps~0.8Mpa

|

|

Power

|

5000~7000w

|

|

Dimension

|

3700*1300*1785mm (L*W*H) (Customized)

|

|

N. Weight

|

350Kg (inspection machine only)

|

Spherical Light Source

Self-developed LED light source imaging unit, full coverage of UV to infrared full spectrum, polarization, fluorescence, and others for more complicated samples.

Integrated Cavity Light Source

Self-developed LED imaging lighting unit, combined with product characteristics, deploys camera layout to provide a good light source environment for visual inspection.

Industrial Camera

Self-developed and customized general industrial camera with special algorithms, higher color reproduction, faster triggering frequency, and higher resolution.

Interaction Interface

Self-developed human&computer interaction system, compatible with multiple protocols, quickly connecting with central control and upstream and downstream devices.

Main Configurations:

|

Items

|

Brand

|

|

Industrial Camera

|

KEYETECH

HIKVISION

|

|

Planar Lens

|

HIKVISION

|

|

Strobe Light Source

|

KEYETECH

|

|

Photoelectric Sensor

|

SICK (Germany)

|

|

Electromagnetic Valve

|

SMC (JAPAN)

|

|

Industrial Power Kit

|

MEANWELL

|

|

Industrial Control

|

HAOTENG ELECTRON

|

|

AI Algorithm System

|

KEYETECH

|

Applications

The visual inspection machine can inspect the cap defects such as black spots, color differences, impurities, threads, compression rings, broken rings, notches, burrs,flash, deformations, size, double gaskets, reverse gaskets, inner plugs, mold numbers on bottle caps , etc and remove the defects from the qualified ones online.

Hot Searches