- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*2500mm 1500*3000mm (can be customized)

-

Cutting Thickness:

-

Depending on the materials

-

Control Software:

-

Cypcut/NC STUDIO

-

Place of Origin:

-

China

-

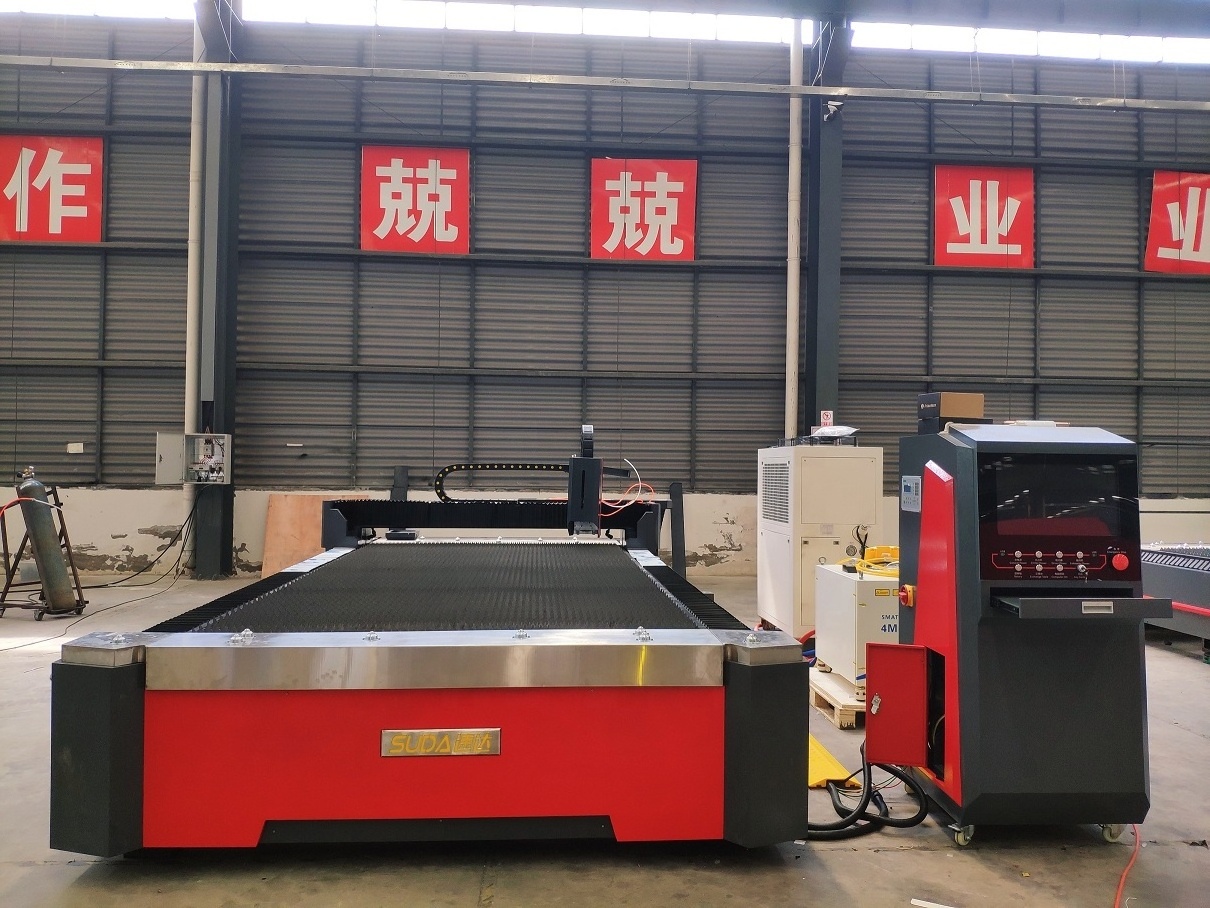

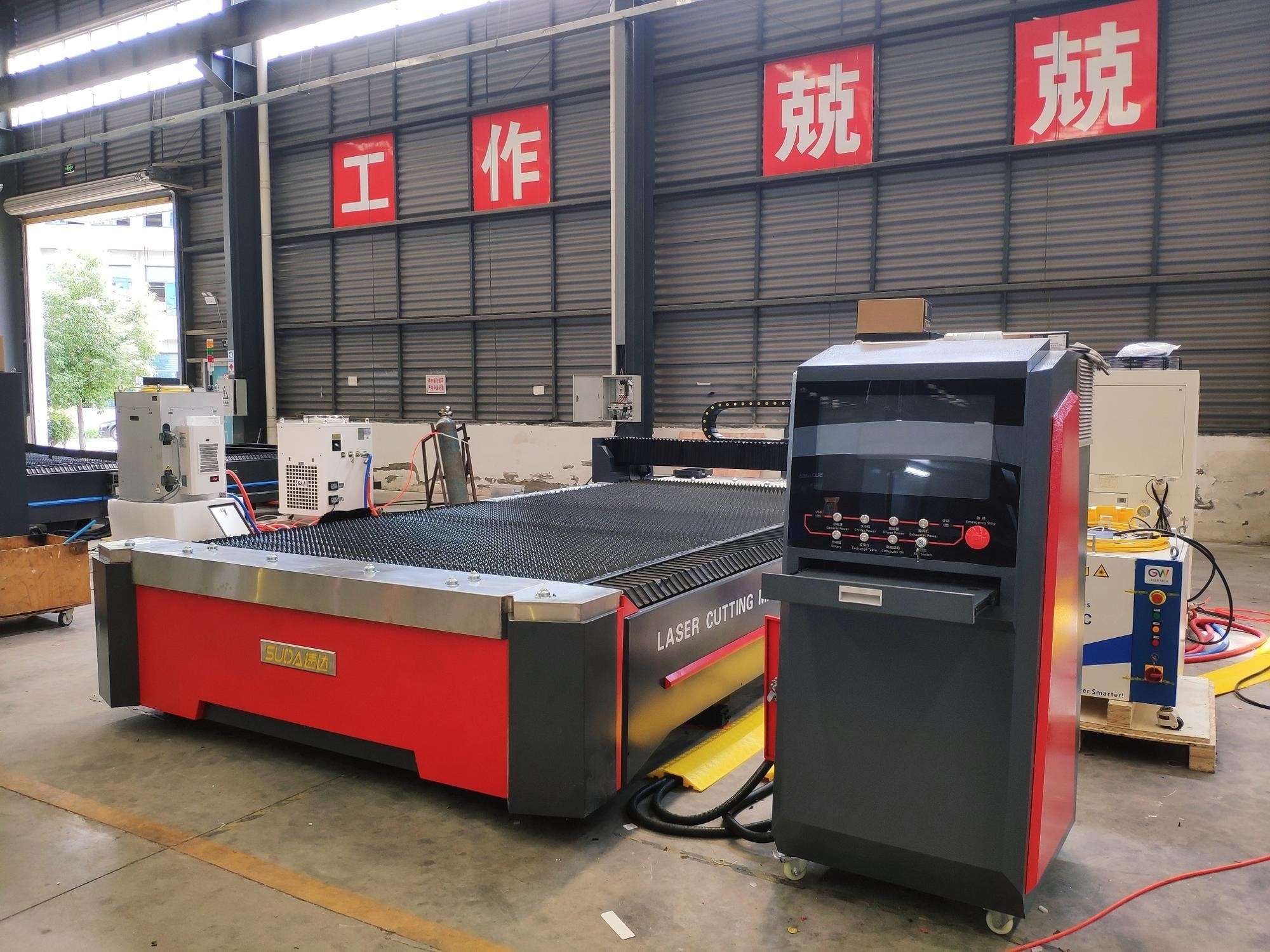

Brand Name:

-

SUDA

-

Weight (KG):

-

3000 KG

-

Product name:

-

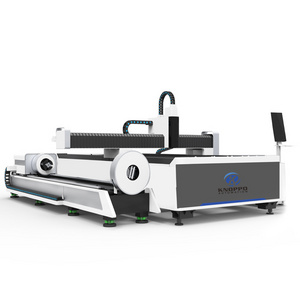

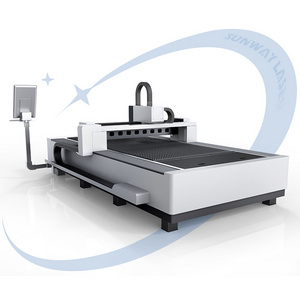

laser metal cutting machines

-

Working area:

-

1300*2500mm 1500*3000mm 1500*4000mm(can be customized)

-

Power:

-

3000w(can be customized)

-

Control system:

-

NC Studio System /CYPCUT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Voltage:

-

220V/380V 50~60Hz

-

Servo system:

-

France Schneider servo system

-

Material:

-

Steel, iron, aluminum, carbon steel, steel plateand various metals

-

Transmission:

-

Gear Rack

-

Keyword:

-

Metal Cutting Machinery

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

Depending on the materials

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*2500mm 1500*3000mm (can be customized)

-

Cutting Thickness:

-

Depending on the materials

-

Control Software:

-

Cypcut/NC STUDIO

-

Place of Origin:

-

China

-

Brand Name:

-

SUDA

-

Weight (KG):

-

3000 KG

-

Product name:

-

laser metal cutting machines

-

Working area:

-

1300*2500mm 1500*3000mm 1500*4000mm(can be customized)

-

Power:

-

3000w(can be customized)

-

Control system:

-

NC Studio System /CYPCUT

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Voltage:

-

220V/380V 50~60Hz

-

Servo system:

-

France Schneider servo system

-

Material:

-

Steel, iron, aluminum, carbon steel, steel plateand various metals

-

Transmission:

-

Gear Rack

-

Keyword:

-

Metal Cutting Machinery

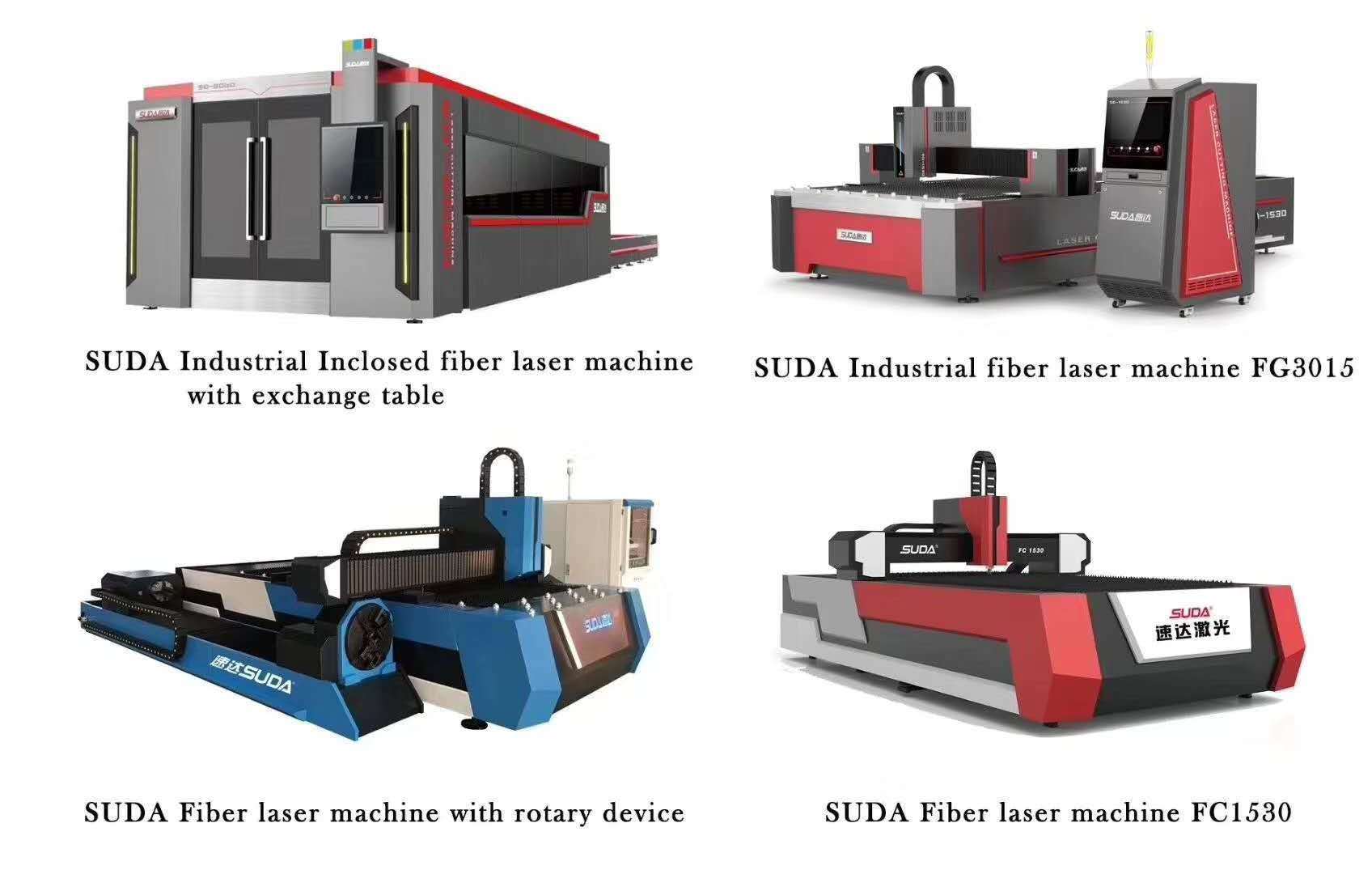

2KW ladder aluminum iron cnc fiber laser cutting machine

Model Features

|

Model Type

|

FG-3015

|

FG-4015

|

FG-6015

|

FG-4020

|

FG-6020

|

||||

|

Cutting Width

|

1500x3000mm

|

1500x4000mm

|

1500x6000mm

|

2000x4000mm

|

2000x6000mm

|

||||

|

Laser Media

|

Fiber Laser

|

|

|

|

|

||||

|

Power

|

750W,1000W,1500W,2000W,3000W,4000W,6000W,10000W,15000W(Optional)

|

|

|

|

|

||||

|

Min Route Width

|

0.1mm

|

|

|

|

|

||||

|

Reposition Accuracy

|

±0.05mm

|

|

|

|

|

||||

|

Wave Length

|

1080nm

|

|

|

|

|

||||

|

Cutting Thickness

|

Depending on the materials

|

|

|

|

|

||||

|

Aiming Positioning

|

Red Dot

|

|

|

|

|

||||

|

Voltage Requirement

|

220V or 380V / 50Hz~60Hz

|

|

|

|

|

||||

|

Linear Rail

|

THK(Japan)

|

|

|

|

|

||||

|

Reducer

|

Shimpo(Japan)

|

|

|

|

|

||||

|

Laser Source

|

Raycus(Standard) / IPG(Optional)

|

|

|

|

|

||||

|

Cutting Head

|

WSX / Raytools

|

|

|

|

|

||||

|

Servo System

|

France Schneider AC servo system

|

|

|

|

|

||||

|

Control System

|

Cypcut / Weihong NC Studio

|

|

|

|

|

||||

Raycus Laser Source

CYPCUT Control System

The best control system in fiber laser machine industry,

It is suitably applied to high power fiber laser machine and can support the rotary device, exchange table and automatic focus cutting head.

WSX Fiber Laser Cutting Head

Our fiber laser machine 1000 watt install the WSX NC30 automatic focus cutting head, Fast perforation (especially the thick materials), The plate is not easy to heat, Does not affect the cutting head following.

France Schneider Servo System

The fiber laser machine adopts the imported servo system from France including servo motor and servo driver, The Y axis two servo motor power are 2KW, The X axis servo power is 2KW power, The Z axis servo motor power is 0.4KW power.

Japan THK Linear Rail and Block

The machine adopts the best linear and block rail from Japan. We have the feedback from our client that its block even can use over 10 years and can't break.

The usage lifespan and the product quality definitely can be ensured.

◆Applicable field: can be used for various metal sheet processing,mainly applicable for high-speed and high-precision cutting of stainless steel,carbon steel,manganese steel,galvanized sheet,alloy sheet and rare metal materials.

◆Applicable industries:

hotel kitchen equipment,hardware products,automobile manufacturing,mechanical equipment,display equipment,precision parts,electrical equipment,elevator equipment,lighting hardware,automobile decoration and other industries.

T ONGXING Technology Development Co.,Ltd established in 1992 , lies in HEFEl --One of Chinese scientific and technology cities.It has been working on researching and manufacturing CNC machinery in field of woodworking,stone engraving,metal processing,glass cutting and advertising etc. over 20 years.

The main products: Heavy moving column CNC machining center,Heavy static column CNC machining center, High accuracy metal cutting machine, High precision fiber laser machine,Vanguard series CNC engraver, Multistage CNC machine center,SUDA high accuracy CNC engraver, SUDA laser cutting machine,fiber cutting machine,totally 23 series ,more than 100 models.

The sales net

not only covers all Chinese provinces and municipalities,including HongKong, Taiwan&Macao,also the products are exported to more than 120 countries and regions such as Europe,America,Middle-east,South-east Asia etc.

Certificate

Joint with global core suppliers

Pre-Sales Service

1. We have many exhibitions very year, hundreds of clients was coming to our booth for further communication.

2. 24-hours online Inquiry and consulting support.

3.Support sample testing .

4.We welcome you to visit our factory.

After-Sales Service

1. Training how to instal the machine, training how to use the machine online.

2. Engineers available to clients' factory for training.

3.Guarantee for one year

4.24-hour technical support by email or calling

5.User-friendly English manual for machine using and maintaining

6.Free technician training for customers.

Customers' feedbacks:

Q1. how to get the most suitable machine and best price?

Please tell me

what's the materials you want to cutting or engraving ?

what's MAX size of carved material ?

Then I will recommend the most suitable model and the best price for you

.

Q2. In case of failure,how to do?

Call us----our engineers are online for 24-hours,and ready to serve you.

Replacement of damaged parts for free---For more information,please contact us

The CD and operation manual----It show the most common failure in working processing and how to solve this problems.

Q3. What is the type of shipping and producing time?

we offer EXW, FOB and CIF which you can choose as you like.

when you pay for the pre-payment, we will arrange producing which about 7--15 days.

If you have any doubt, ples contact with me, l will reply for you in time.