- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GREATCITY

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 kg

-

Year:

-

latest production

-

Feeding width:

-

1220mm,and so on

-

Product name:

-

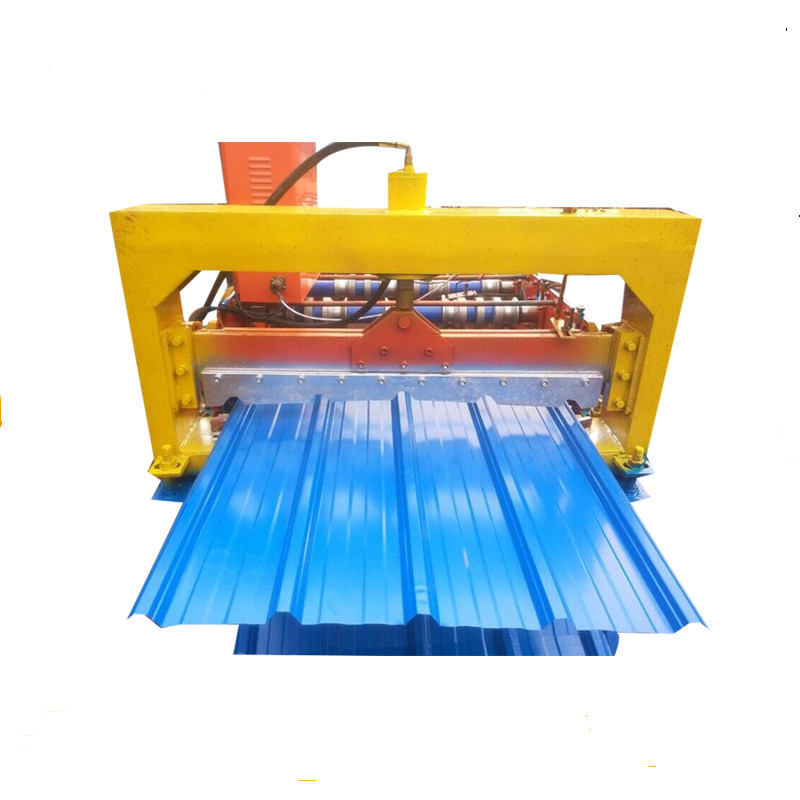

Factory hot promotion automatic roof panel cold roll forming machine

-

color:

-

blue/red/yellow/and so on

-

raw materials:

-

colord steel sheet or Galvanized steel sheet

-

voltage:

-

380v 50HZ 3PHASES or customized

-

work efficiency:

-

8-15m/miniute

-

usage:

-

roof sheet

-

Roller material:

-

High-grade 45# Steel

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Certification:

-

CE

-

Control system:

-

PLC(detla) System

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-12m/minute

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GREATCITY

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

2500 kg

-

Year:

-

latest production

-

Feeding width:

-

1220mm,and so on

-

Product name:

-

Factory hot promotion automatic roof panel cold roll forming machine

-

color:

-

blue/red/yellow/and so on

-

raw materials:

-

colord steel sheet or Galvanized steel sheet

-

voltage:

-

380v 50HZ 3PHASES or customized

-

work efficiency:

-

8-15m/miniute

-

usage:

-

roof sheet

-

Roller material:

-

High-grade 45# Steel

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Certification:

-

CE

-

Control system:

-

PLC(detla) System

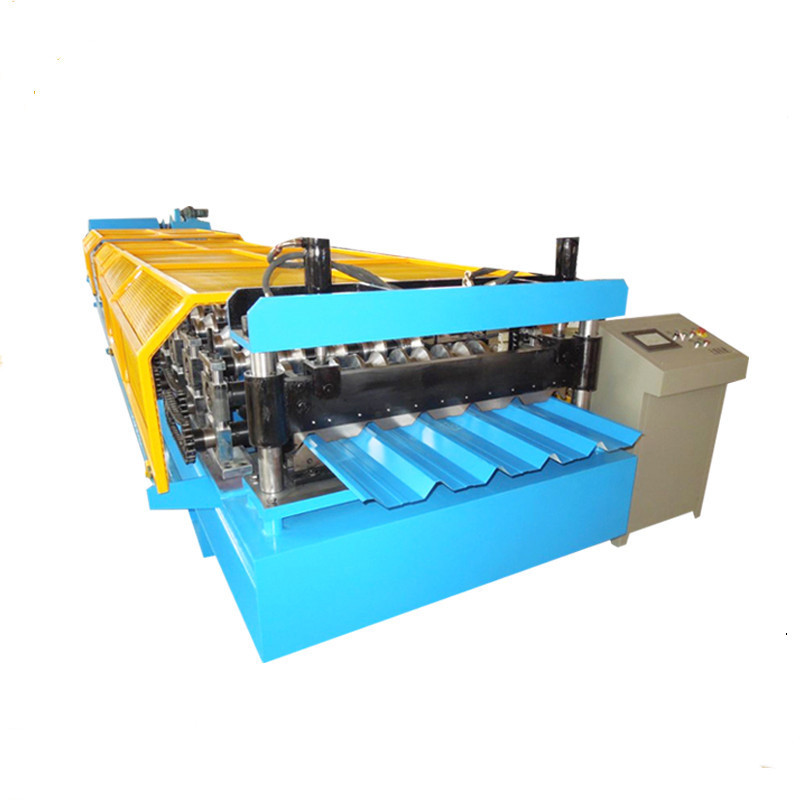

Factory hot promotion high speed automatic roof panel cold roll forming machine

Specification of roof panel roll forming machine:

All the technical parameters are also made as per the cutomers' requirements.

| 1.Weight capacity of decoiler | 3T |

| 2.Appearance Size(L*W*H) | 6500*1500*1500 |

| 3.Raw material /feeding sheet material | Colored steel & galvanized steel |

| 4.Roller material | 45# high grade steel |

| 5.Shaft material | 45# high grade steel |

| 6.Kind of drive | Chain drive |

| 7.Cutting system | Automatic hydyaulic cutting |

| 8.Cutting blade material | Cr 12 high grade steel |

| 9.Frame material | 300 H-high grade steel |

| 10.Control system | Totally automatic PLC control system |

| 11.Main power | 3 kw |

| 12.Roller stations | 13 rows |

| 13.Speed of production | 8-12m/min |

| 14.Thickness of colored steel | 0.2-0.8mm |

| 15.Feeding width | 1000mm |

| 16.Effectiv width | 840/900mm |

| 15.Frame material | 300 H-steel |

The detailed photos of roof panel Roll forming machine:

roof panel forming machine

Workflow

:

Decoiler→Flating→Feeding→Forming→Cut to length→Collection(finish goods)