- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+_2MM

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

OK

-

Dimension(L*W*H):

-

2700X2000X2200MM

-

Weight:

-

4200 KG

-

Product name:

-

water filling machine

-

Model:

-

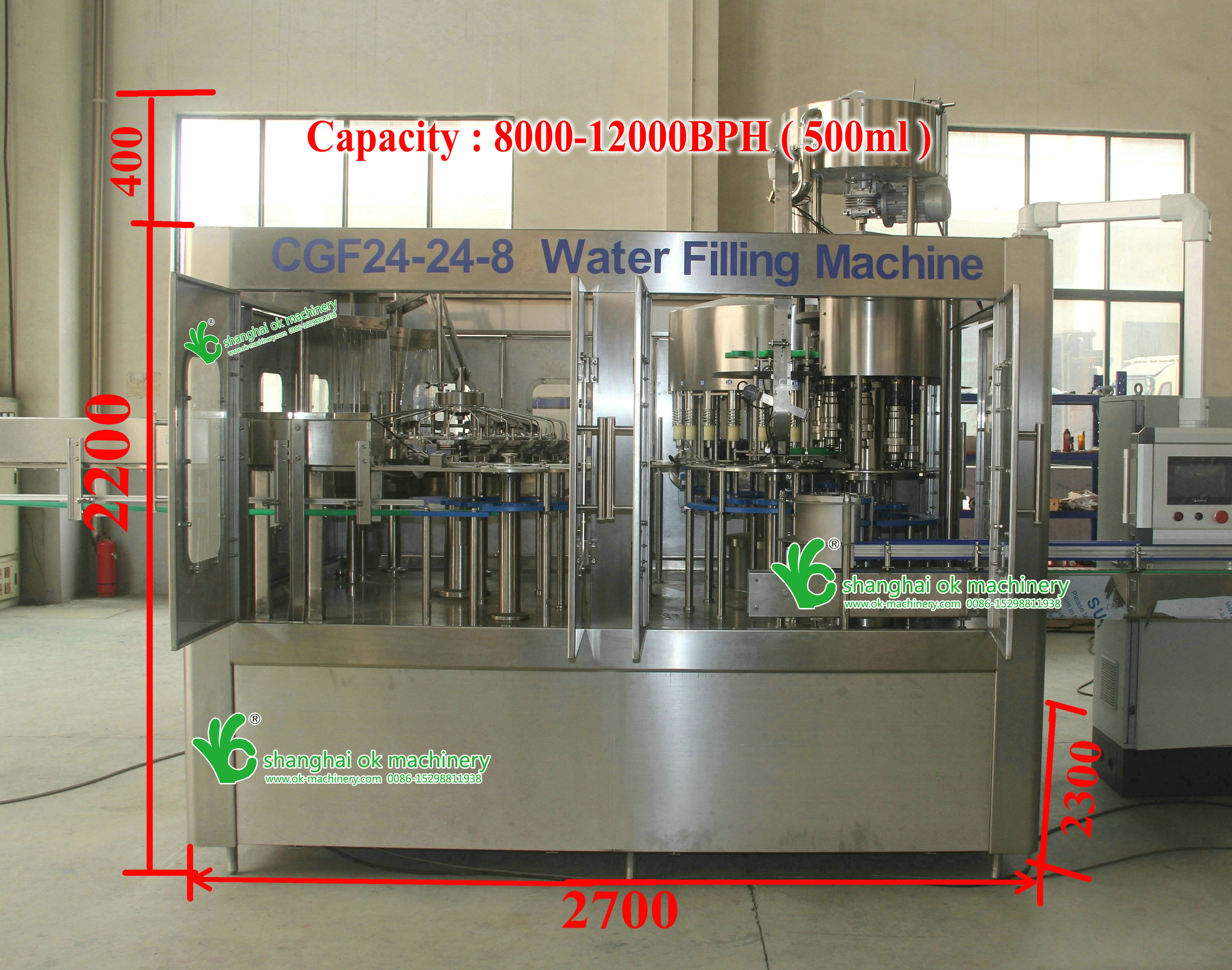

XGF24-24-8

-

Capacity:

-

12000BPH

-

Filling material:

-

Liquid beer

-

Function:

-

bottle Washing Filling Capping

-

Product:

-

Bottle drinking beer

-

Keywords:

-

Drinking beer Production Plant

-

Bottle volume:

-

220ml to 2500ml

-

Bottle type:

-

Round Bottle

-

Control:

-

PLC+ Touch Screen

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Filling Material:

-

Beer, Water, Oil, Juice

-

Filling Accuracy:

-

+_2MM

-

Voltage:

-

380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

OK

-

Dimension(L*W*H):

-

2700X2000X2200MM

-

Weight:

-

4200 KG

-

Product name:

-

water filling machine

-

Model:

-

XGF24-24-8

-

Capacity:

-

12000BPH

-

Filling material:

-

Liquid beer

-

Function:

-

bottle Washing Filling Capping

-

Product:

-

Bottle drinking beer

-

Keywords:

-

Drinking beer Production Plant

-

Bottle volume:

-

220ml to 2500ml

-

Bottle type:

-

Round Bottle

-

Control:

-

PLC+ Touch Screen

Product Description

XGF series bottled water filling machine line is used to filling mineral water or purified water into PET bottle from

200ml 2000ml.Different models can satisfy various requirement of output from 2000 to 36000BPH.The machine

combines washing,filling and capping three function in a body, the whole process is automatic, suitable for PET bottle, plastic bottle filling mineral water and pure water.Filling way using the gravity or micro pressure filling, make the speed is faster and morestable, so with the same model our machine output is higher and more efficient.The machine adopts advanced Mitsubishi programmable controller (PLC) to control the machine to run automatically, inter working with inverter running more stable and

reliable.The photoelectric sensor detect all part running state, with high degree of automation, easy operation.

BKBK02 Full Automatic 3 in1 Drinking bottle water filling machinehigh speed bottle water filling machine video

This video is xgf24-24-8 water filling machine , machine capacity 12000 bottles/hour , machine bottle voume can 200ml to 2500ml , machine material food standard stainless steel .

3 in 1 bottle Water production line video . This video will show you washing bottle inside and outside , filling liquid into bottle put cap on bottle and capping it,after all will inlet with flat conveyor belt .Bottle line automatic water filling machine /bottle water filling machine for sale.

|

Model

|

XGF14-12-5

|

XGF16-16-5

|

XGF24-24-8

|

XGF32-32-8

|

|

Capacity

|

5000BPH

|

8000BPH

|

12000BPH

|

15000BPH

|

|

Bottle Volume

|

200ml-2500ml

|

200ml-2500ml

|

200ml-2500ml

|

200ml-2500ml

|

|

Bottle diameater

|

50-110mm

|

50-110mm

|

50-110mm

|

50-110mm

|

|

Bottle high

|

150-320mm

|

150-320mm

|

150-320mm

|

150-320mm

|

|

Machine power

|

1.5KW

|

2.2KW

|

3.7KW

|

5.5KW

|

|

Machine size

|

235x177x225CM

|

270x200x225CM

|

280x210x225CM

|

355x265x225CM

|

Function Declaration

Windy conveyor

this part is windy conveyor belt , the bottle go out from bottle blowing machine , will go to water filling machine .connect bottle blowing machine to water filling machine use this windy conveyor part .

Bottle washing part

this is bottle washing part , use pure water rinsing bottle inside and outside , before filling water . the dust inside bottle can cleaning . this bottle rinsing part material is stainless steel .

Bottle filling part

this part just filling water into bottle , filling tank and filing nozzle both stainless steel , filling nozzle design is new fast filling speed nozzle design , filling water fast and stable than before old filling nozzle .

Bottle capping part

this xgf24-24-8 water filling machine have 8 heads , speed is about 12000 bottles/hour , capping heads also use stainless steel making , whole capping heads can easy take off to change , good design easy change and repair .

Detail of OK Machine

Machine Runing Video

OK Machine Advantages

Automatic Cap online sterilizer

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Automatic cap loader

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Flat Conveyor

- Energy saving. High efficient. Adapt to customer factory layout - Special lubrication system, keep products clean, health, safety - Extended service life

- Electric eyes design keep whole line running safety and quickly - Overload protection mechanism to effectively ensure the safety of the machine

- Electric eyes design keep whole line running safety and quickly - Overload protection mechanism to effectively ensure the safety of the machine

Air Conveyor

- Air conveyor is fixed on the floor, with fan installed on the top. - Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles. - Bottles are held on the neck in the conveyor and transported into filling machine by blowing power. - All are made of stainless steel SUS 304 /316. - Rack made by high quality carbon steel welded.

1. All Stainless Steel

1. Filling machine air conveyor

SUS304

2. Washing part

SUS304

3. Filling tank and nozzle

SUS316

4. Capping heads

SUS304

5. Machine frame

SUS304

6. Filling machine flat conveyor

SUS304

2. NSK Gear (Janpan)

Nsk Gear use in ok filling machine

model list

1.

NSK Gear

Model 6006

2.

NSK Gear

Model

6203

3.

NSK Gear

Model 6805

4.

NSK Gear

Model 6002 6204 ......

3. Festo (Germany)

OK machine control System

Touch screen

SIEMENS

PLC

SIEMENS

Inverter

SIEMENS

Air action control

Festo Germany

AC contactor

SIEMENS

Related Products

1. Bottle blowing machine

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

2. Water treatment system

Stainless steel high pressure film shellAll kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system Online type pressure auto self-protection device Online type electricity indicator System safe protecting and alarm system System frame

3. Shrinking label machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink

sleeve machine, that is, four-wheel driving, self-centering and balanced pressure of four wheels.

Customer Photos

Company Introduction

Shanghai OK Machinery co.,Ltd is located in Zhangjiagang,Jiangsu province. We own professional design and sell team.We are a leading enterprise in making full set bottle water production line ,bottle juice,carbonated soft drinking beverage,glass bottle beer,label machine packing machine gathering development, designing, production, technology service and marketing.

Our company according to China situation, we developed full- set equipments for liquid and high automatic advanced technology.

We will try our best to meet the demands of our customers continually and seek for development together with our customer.

Welcome you visit our factory to checking machine quality.

Our company according to China situation, we developed full- set equipments for liquid and high automatic advanced technology.

We will try our best to meet the demands of our customers continually and seek for development together with our customer.

Welcome you visit our factory to checking machine quality.

After Sales Service

1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality,

specification and function all meet the demand of contract. We promise that the products of this line could storage for one

year without adding any aseptic.

4. After sales

After checking, we offer 2 yearsas quality guarantee, free offer wearing parts and offer other parts at the lowest price. In

quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician. After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If the problems are still can not solve, we will arrange technician to your factory solving the problems. automatic water filling machine video

BKCC01 Automatic water filling line plant/water filling production line/water filling machine

FAQ

Q1: Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,you can go to vist their factory.

And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city. Our sales people you can get video of our reference running machineIn our nearby city has a Coca cola factory, they are buy our machine, we can take you to visit.

Q2: Do you have agent and after-service stations?

A2: So far we have agent in Indonsia, Malaysia, Vietnam, South Africa, Thailand etc.. welcome to join us!

Q3: Do you provide customized service

A3: We can design the machines according your requirements(materil ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q4: What's your guarantee or the warranty of the quality if we buy your machines?

A4: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q5: How long time for installation?

A5: According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality,

specification and function all meet the demand of contract. We promise that the products of this line could storage for one

year without adding any aseptic.

4. After sales

After checking, we offer 2 yearsas quality guarantee, free offer wearing parts and offer other parts at the lowest price. In

quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician. After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If the problems are still can not solve, we will arrange technician to your factory solving the problems. automatic water filling machine video

BKCC01 Automatic water filling line plant/water filling production line/water filling machine

FAQ

Q1: Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,you can go to vist their factory.

And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city. Our sales people you can get video of our reference running machineIn our nearby city has a Coca cola factory, they are buy our machine, we can take you to visit.

Q2: Do you have agent and after-service stations?

A2: So far we have agent in Indonsia, Malaysia, Vietnam, South Africa, Thailand etc.. welcome to join us!

Q3: Do you provide customized service

A3: We can design the machines according your requirements(materil ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q4: What's your guarantee or the warranty of the quality if we buy your machines?

A4: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q5: How long time for installation?

A5: According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Hot Searches