- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

EPG

-

Item:

-

standard or nonstandard spur gear

-

OEM Service:

-

yes

-

Free Sample:

-

spur gear

Quick Details

-

Weight (KG):

-

10

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

Customized

-

Brand Name:

-

EPG

-

Item:

-

standard or nonstandard spur gear

-

OEM Service:

-

yes

-

Free Sample:

-

spur gear

Products Description

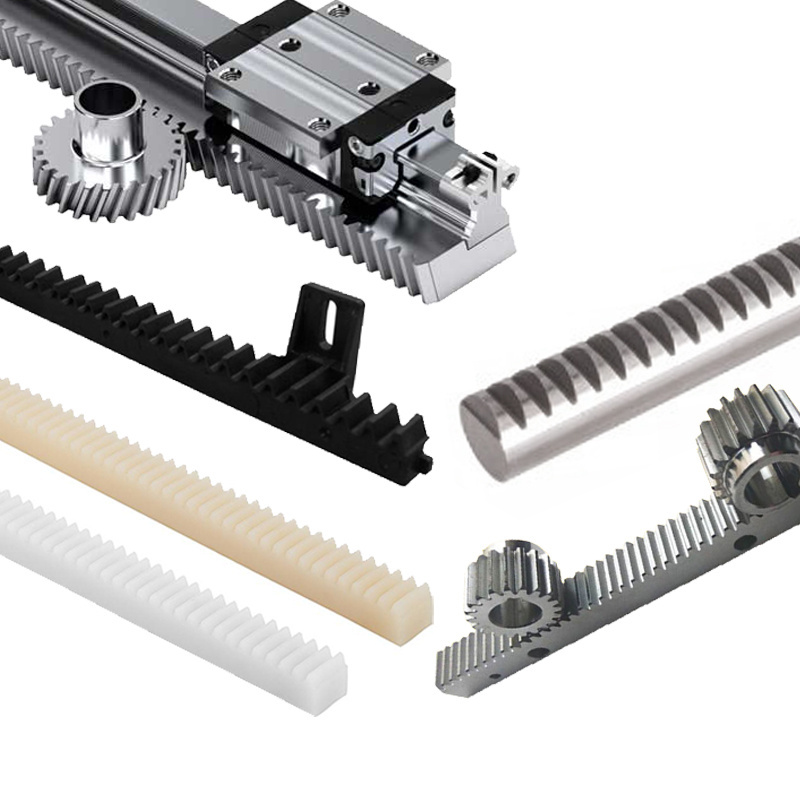

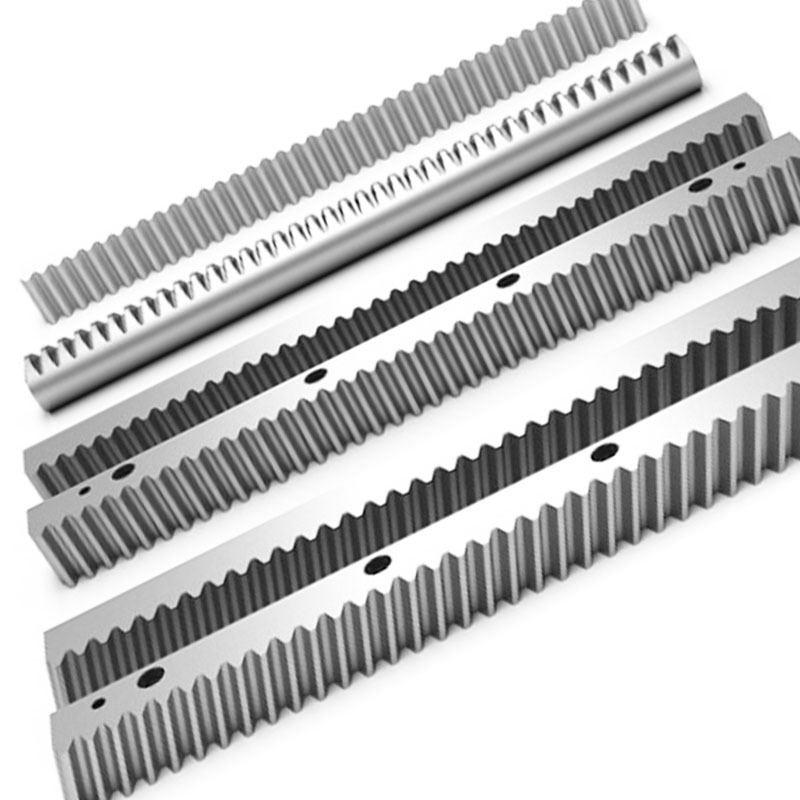

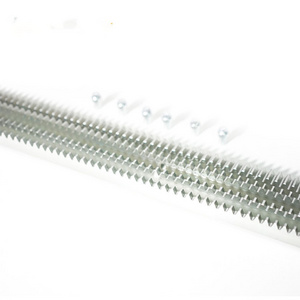

Gear rack

Spur Gear/Bevel Gear/Helical Gear/Spiral Bevel Gear and rack

The rack can be classified according to tooth shape, gear shape, tooth line shape, manufacturing process and other methods.

Application

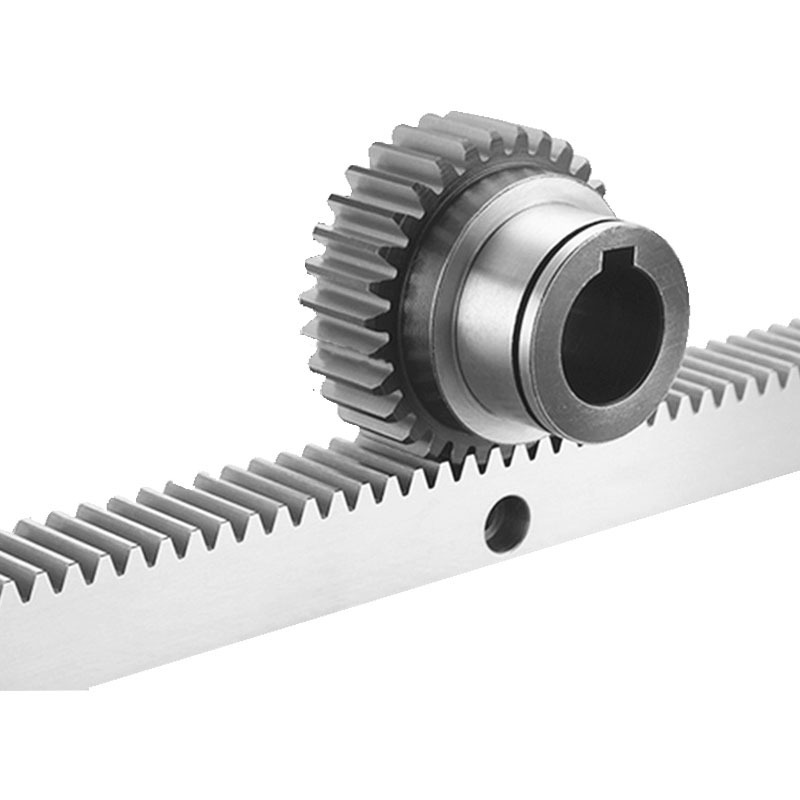

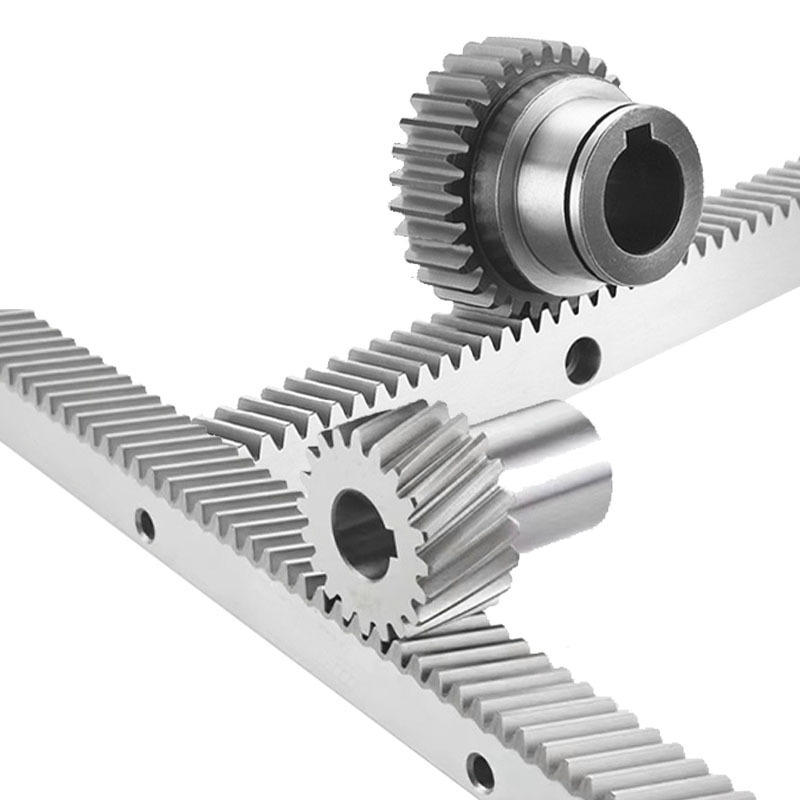

The working principle of gear and rack is to convert the rotary motion of gear into the reciprocating linear motion of rack, or convert the reciprocating linear motion of rack into the rotary motion of gear.

1. Suitable for fast and accurate positioning mechanism 2. It is suitable for CNC machine tools, machining centers, cutting

machines, welding machines, etc. with heavy load, high precision, high rigidity, high speed and long stroke 3. It is suitable for factory automation rapid transplanting machinery, industrial robot arm grabbing mechanism, etc

Gear rack processing method: (1) hobbing (2) gear shaping (3) gear shaving (4) gear grinding (5) gear honing

Before selecting the rack, you need to know these parameters of the rack: Tooth slot width, tooth top height, tooth root height, tooth height, tooth thickness, tooth root circle radius

The working principle of gear and rack is to convert the rotary motion of gear into the reciprocating linear motion of rack, or convert the reciprocating linear motion of rack into the rotary motion of gear.

1. Suitable for fast and accurate positioning mechanism 2. It is suitable for CNC machine tools, machining centers, cutting

machines, welding machines, etc. with heavy load, high precision, high rigidity, high speed and long stroke 3. It is suitable for factory automation rapid transplanting machinery, industrial robot arm grabbing mechanism, etc

Gear rack processing method: (1) hobbing (2) gear shaping (3) gear shaving (4) gear grinding (5) gear honing

Before selecting the rack, you need to know these parameters of the rack: Tooth slot width, tooth top height, tooth root height, tooth height, tooth thickness, tooth root circle radius

|

According to the shape of gears

|

cylindrical gears, straight teeth, helical teeth;

|

|

According to the shape of the tooth line

|

spur gear, helical gear, herringbone gear;

|

|

According to the process

|

quenching, tempering, grinding, gear milling, gear grinding, blackening treatment according to needs

|

|

Material

|

C45,40Cr,20CrMnTi,42CrMo, Copper, Stainless steel and so on as per your requests.

|

|

Processing

|

Forging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment....…

|

|

Heat Treatment

|

Carburizing,Induction,Flame,Nitriding....…

|

|

Main Machines

|

NC Gear Hobbing Machines, NC Gear Shapers(Gealson, Moude), NC lathe, NC gear Shaving machines, NC gear milling, Nc gear grinding

Machines and many kinds of gear related machines. |

Recommend Products

Hot Searches