- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/110V

-

Current:

-

dependable, Dependable

-

Rated Capacity:

-

6400W

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

L600*W640*H850mm

-

Use:

-

automatic bga rework station

-

Product name:

-

automatic bga rework station

-

PCB size:

-

max 410*380mm min 10*10mm

-

Temperature control:

-

independent temperatue control ,up to ±3℃

-

PCB positioning:

-

v-groove+universal fixture

-

Min PCB size:

-

10mm*10mm

-

Business type:

-

Manufacturer with 10 years' domestic experience

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

China

-

Warranty:

-

1 YEAR

-

Weight (KG):

-

85kg

-

Voltage:

-

220V/110V

-

Current:

-

dependable, Dependable

-

Rated Capacity:

-

6400W

-

Rated Duty Cycle:

-

100%

-

Dimensions:

-

L600*W640*H850mm

-

Use:

-

automatic bga rework station

-

Product name:

-

automatic bga rework station

-

PCB size:

-

max 410*380mm min 10*10mm

-

Temperature control:

-

independent temperatue control ,up to ±3℃

-

PCB positioning:

-

v-groove+universal fixture

-

Min PCB size:

-

10mm*10mm

-

Business type:

-

Manufacturer with 10 years' domestic experience

-

Certification:

-

CE ISO

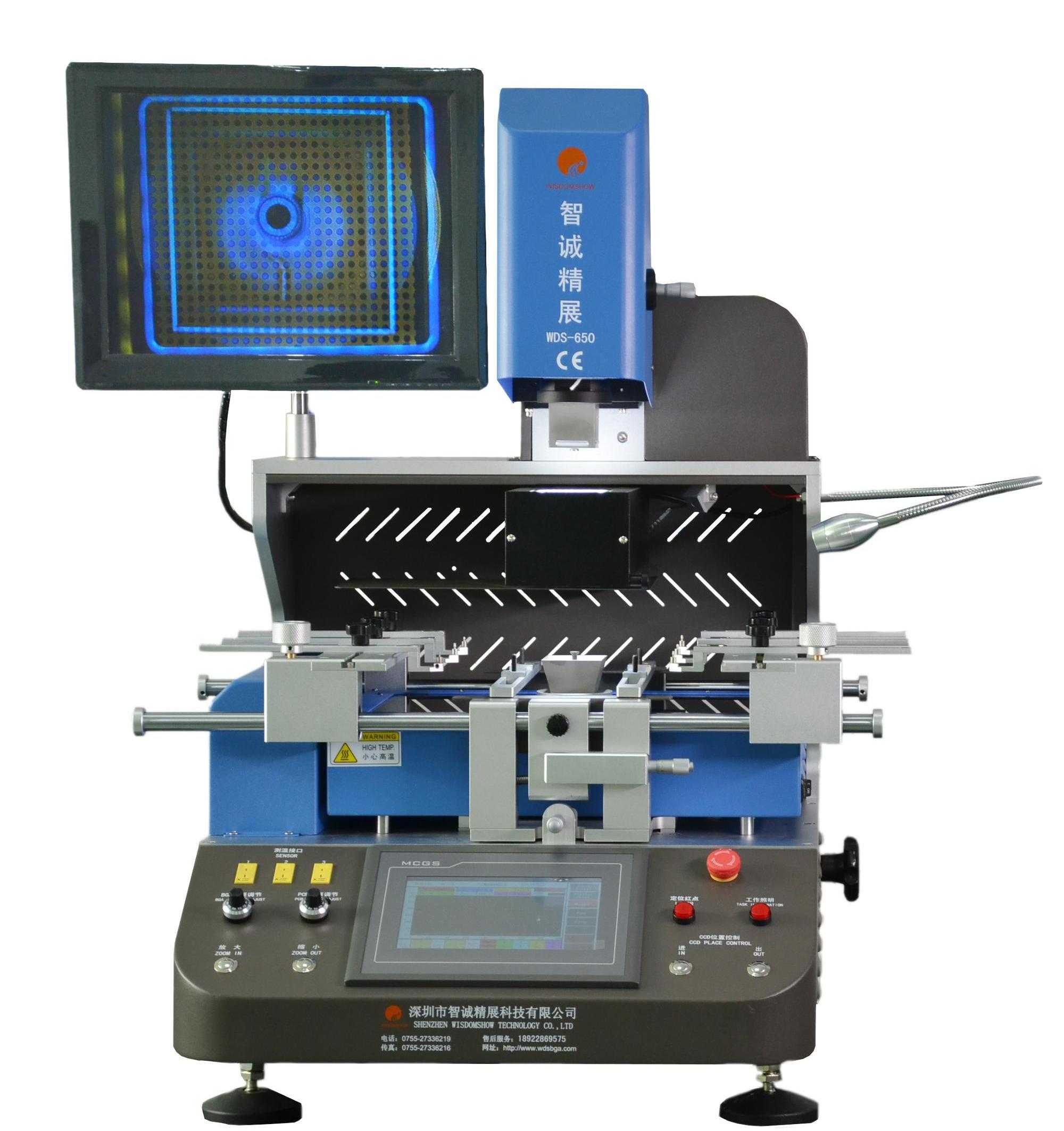

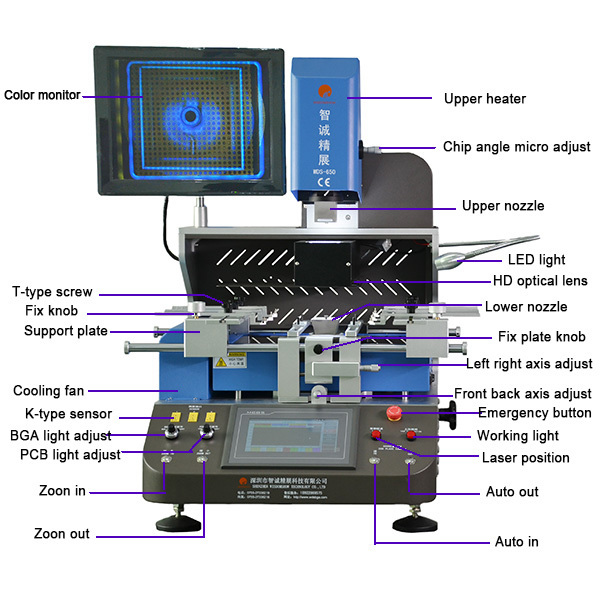

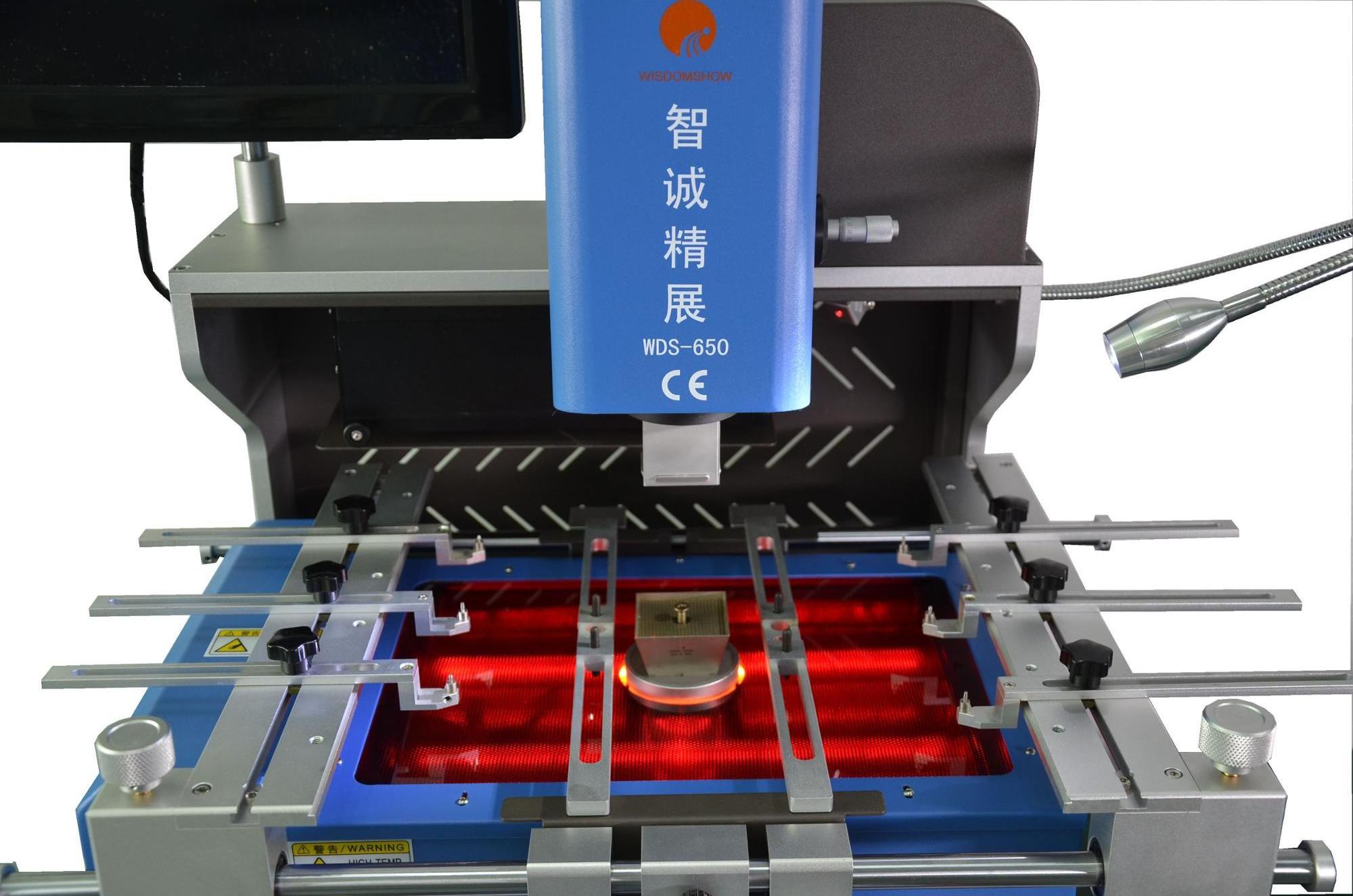

PC motherboard repair machine WDS 650 Automatic BGA rework station with laser position

Application of WDS-650 automatic bga rework station :

→Laptop / Notebook/ Computer motherboard repair.

→ Playstation / XBOX 360 and other game console repair.

→ Iphone 4/ 4s / 5 / 5s /6 /6s /7 /7s motherboard repair.

→ TV / Video / ipad mainboard repair.

→ SMD/ SMT / IC / VGA BGA rework .

Parameter of WDS-650 automatic bga rework station :

| Place of Origin |

Guangdong , China |

| Brand Name | Wisdomshow |

|

Mode Number |

WDS-650 bga rework station |

| Superior function | ic chip soldering and desoldering |

Detail Sepcification :

| Power | AC 220V±10% 50/60Hz 5.4k VA |

|

Total Power |

max 6400W |

|

Heater power

|

upper temp.zone 1200w, second temp.zone 1200w, IR temp.zone 4000w |

| Temperature Controlling |

K-sensor closed loop control ,independent temperature control

|

|

PCB size |

Max : 410*380 mm Min: 10*10 mm |

|

BGA Application |

Max 70mm*70mm Min 1mm*1mm |

| Thermocouple Ports | 3 units |

| Chip Blowup Diploid | 2-50X |

| Alignment system | Optical lens + HD industrial camera |

| Tip spot mnitoring | Optical external camera to monitor solder ball melting process during welding |

Feature of WDS-650 automatic bga rework station :

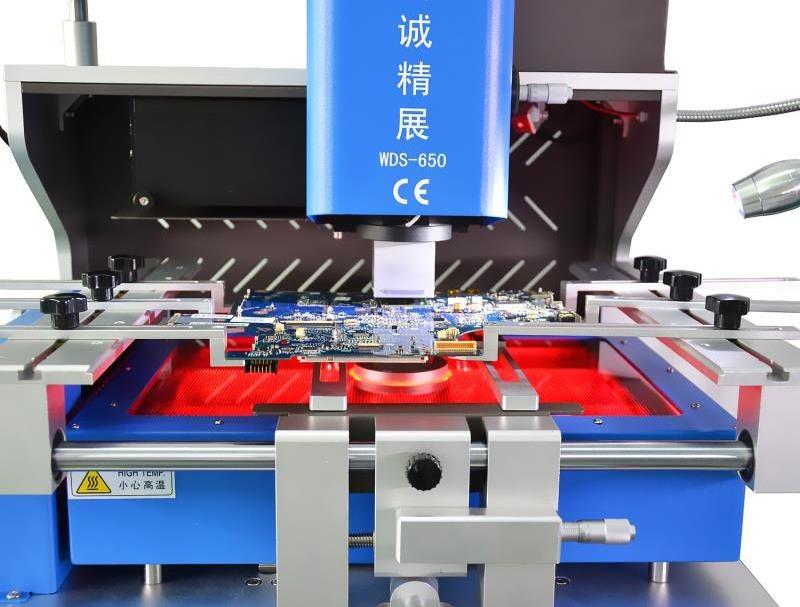

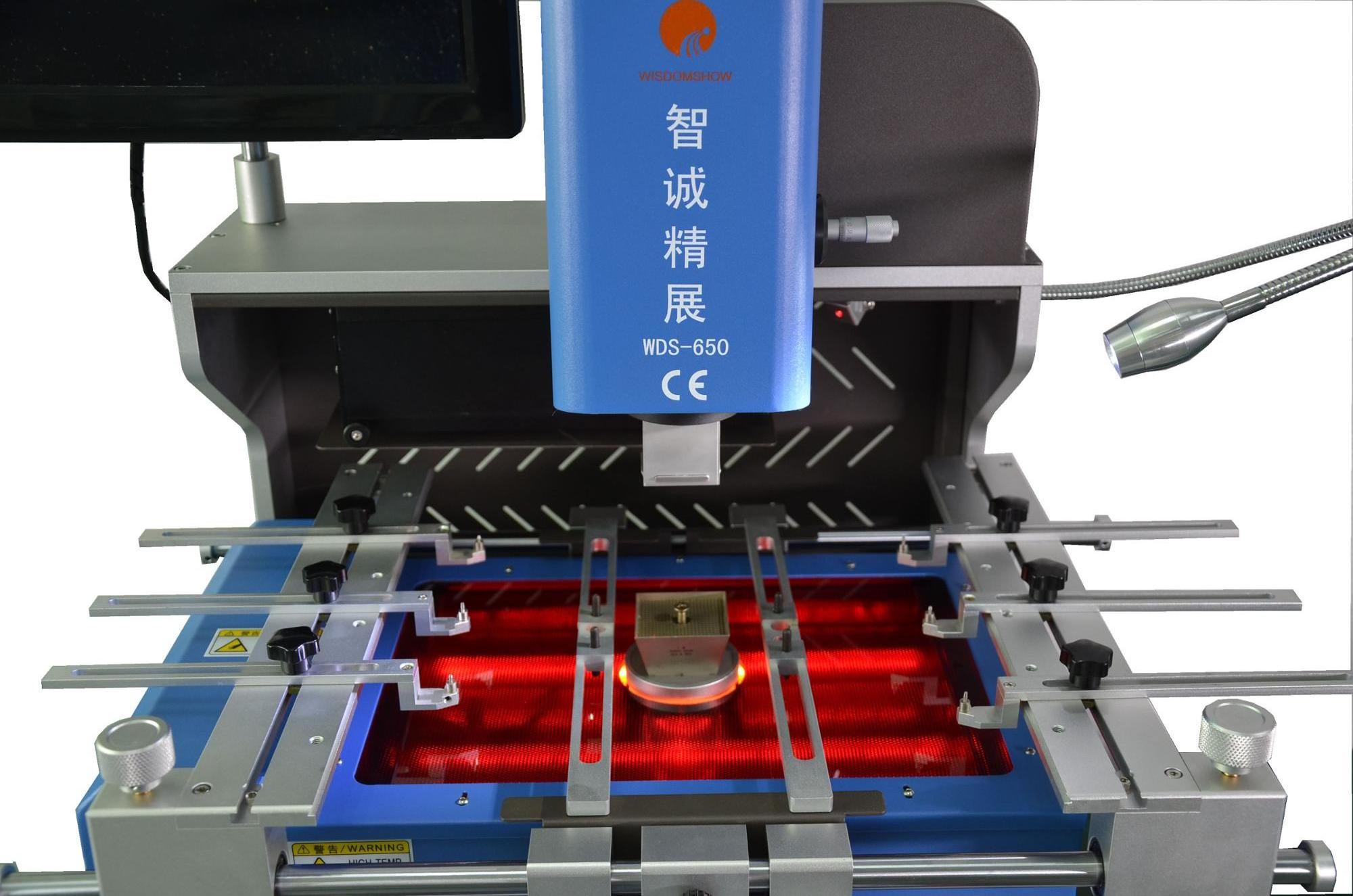

» » Independent 3 heating zones temperature control system

1.The upper and lower hot air heating, IR preheating zone adopts imported infrared gold-plated light tube to heat up quickly,which can heat up at the same time from the top of he component to the bottom of the PCB, to make the PCB board heated averagely,ensure welding effect;bottom IR heating,temperature precision control within ±1℃.8 segment temperature control independently.Infrared gold-plated light tube control heating independently.

2.Hot air district heating for BGA and PCB at the same time,and large area IR heater preheating up for the bottom of PCB to avoid completely PCB deformation during reworking,the upper or lower temperature zones could be used alone and combine freely the energy of up and lower heating element.

3. Adopted high precision K-type thermocouple close-loop control and PID parameter self-setting system; automatic bga rework station

4. temperature curves can be displayed with instant curve analysis function and multi-group user data can be saved;temperature can be tested precisely through external measurement interface,curves can be analysed,set and correct on the touch screen at any time.

» » Precision optical alignment system

Using high definition and adjustable CCD color optical alignment system,beam split,amplification, lessening,fine adjustment and auto focus with the function that automatic color aberration resolution and brightness adjustment,adjustable image contrast;equipped with 15 ” high definition LCD monitor.

» » Multi-functional and humanized operation system

1.Adopting the HD touch human-machine interface;upper heating head and mounting head designed 2 in

1;providing many kinds of titanium alloy BGA tuyere can be rotated in 360 degree for easy installation

and replacement.

2.X,Y and R angle adopted micrometer fine-tuning,accuracy locating,precision can reach ±0.01mm.

» » Superior safety protection function

With the alarm function, after the BGA welding the machine can alarm by itself.In the case of

temperature abuse, the circuit can power off automatically with the double over-temperature

protection.Temperature parameter having password protection to prevent any modification.