- Product Details

- {{item.text}}

Quick Details

-

Power:

-

205

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

18.5*7*20

-

Product name:

-

Corn Grinding Mill

-

Application:

-

Food Flour Grinding Mill Machine

-

Advantage:

-

Low Consumption High Efficiency

-

Item:

-

Small-size Corn Milling Machine

-

Related Maize Mill Equipment:

-

Maize Grit Making

-

Keywords:

-

Automatic Maize Flour Milling Machine

-

Color:

-

Customers' Requirement

-

Main product:

-

Flour

-

Type:

-

Maize Corn Milling Machine Plant

-

Processing:

-

Full-automatic Milling Machine

Quick Details

-

Place of Origin:

-

Hainan, China

-

Brand Name:

-

Fuerstar

-

Voltage:

-

380V

-

Power:

-

205

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

18.5*7*20

-

Product name:

-

Corn Grinding Mill

-

Application:

-

Food Flour Grinding Mill Machine

-

Advantage:

-

Low Consumption High Efficiency

-

Item:

-

Small-size Corn Milling Machine

-

Related Maize Mill Equipment:

-

Maize Grit Making

-

Keywords:

-

Automatic Maize Flour Milling Machine

-

Color:

-

Customers' Requirement

-

Main product:

-

Flour

-

Type:

-

Maize Corn Milling Machine Plant

-

Processing:

-

Full-automatic Milling Machine

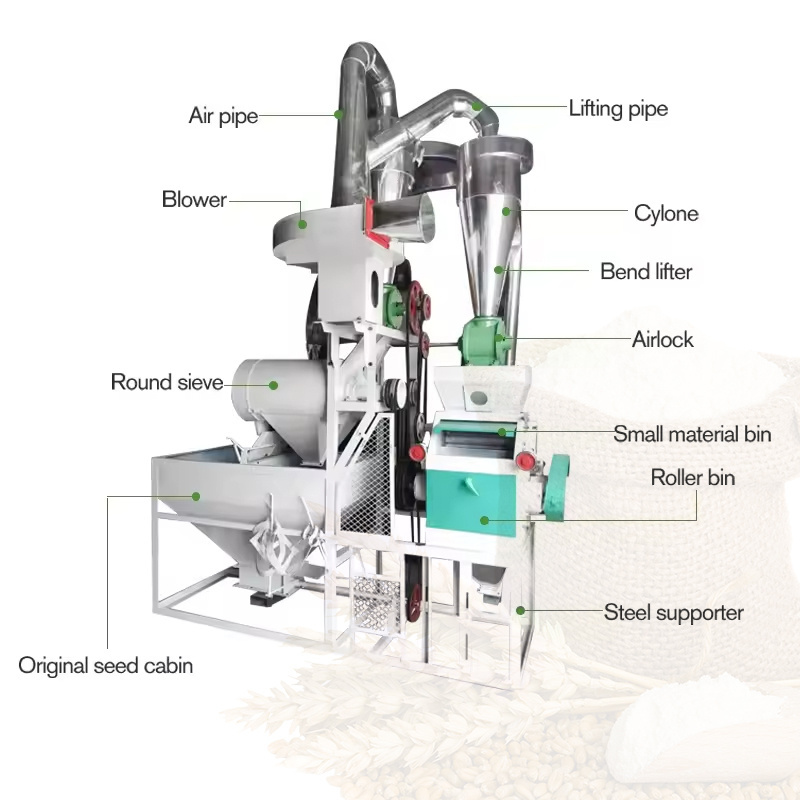

Products Description

Cost-effective, Efficient and User-Friendly Small Automatic Flour Mill for Grinding Corn, Wheat, Sorghum, Grains, Etc.

Henan Ocean

Machinery is a leading grain processing machinery manufacturer in China. Offer not only single flour mill machine, but also small flour mill plant (2TPD ~ 10TPD) and complete set of flour processing plant (20-1000TPD) for processing wheat, corn, cereals and so on. We have helped our customers to set up flour mill projects in many regions, like Ghana, Zambia, Argentina, Ethiopia, Uganda, etc.. Depending on the reliable quality, reasonable price and professional experiences, Henan Ocean Machinery is definitely the Best choice!

Main Features

1. Use the simplest way to complete automatic feeding, realize continuous milling, and greatly reduce the labor intensity of

workers;

2. The use of pneumatic conveying reduces dust and protects the working environment; the use of cyclone dust collectors solves the problem of easy blockage of processed flour;

3. Reduce the temperature of the material under grinding;

4. Simple operation and maintenance, small investment and quick results;

workers;

2. The use of pneumatic conveying reduces dust and protects the working environment; the use of cyclone dust collectors solves the problem of easy blockage of processed flour;

3. Reduce the temperature of the material under grinding;

4. Simple operation and maintenance, small investment and quick results;

|

Model

|

Capacity(Kg/h)

|

Power(Kw)

|

Weight(Kg)

|

Dimension(mm)

|

|

6F35

|

300

|

9.7

|

800

|

2450*1000*3500

|

|

6F40

|

350

|

13.2

|

1000

|

2450*1000*3500

|

|

6F50

|

500

|

17.2

|

1500

|

2550*1000*3500

|

6F SELF-FEEDING ROLLER MILL

It is the upgrade of small roller mill 6F. Instead of manual feeding during each cycle of milling, this machine is pneumatic lifting for the reason of high pressure air blower application and small tank with two bins as a shift surge one. It can save a lot of labor force which can increase the milling capacity at some degree.

Success Cases

With more than 20 years of experience in the field of milling, Henan Ocean aims to provide customers with first-class design work, high-quality machinery and equipment and perfect technical service system. We provide turnkey projects of design, manufacture, installation and commissioning for both domestic and overseas markets.

We implement a strict quality management system in accordance with the requirements of ISO9001 and provide coordinated process services including plant layout, process flow and installation technical guidance.

If you want to know more details about flour milling machine price, please contact us.

Hot Searches