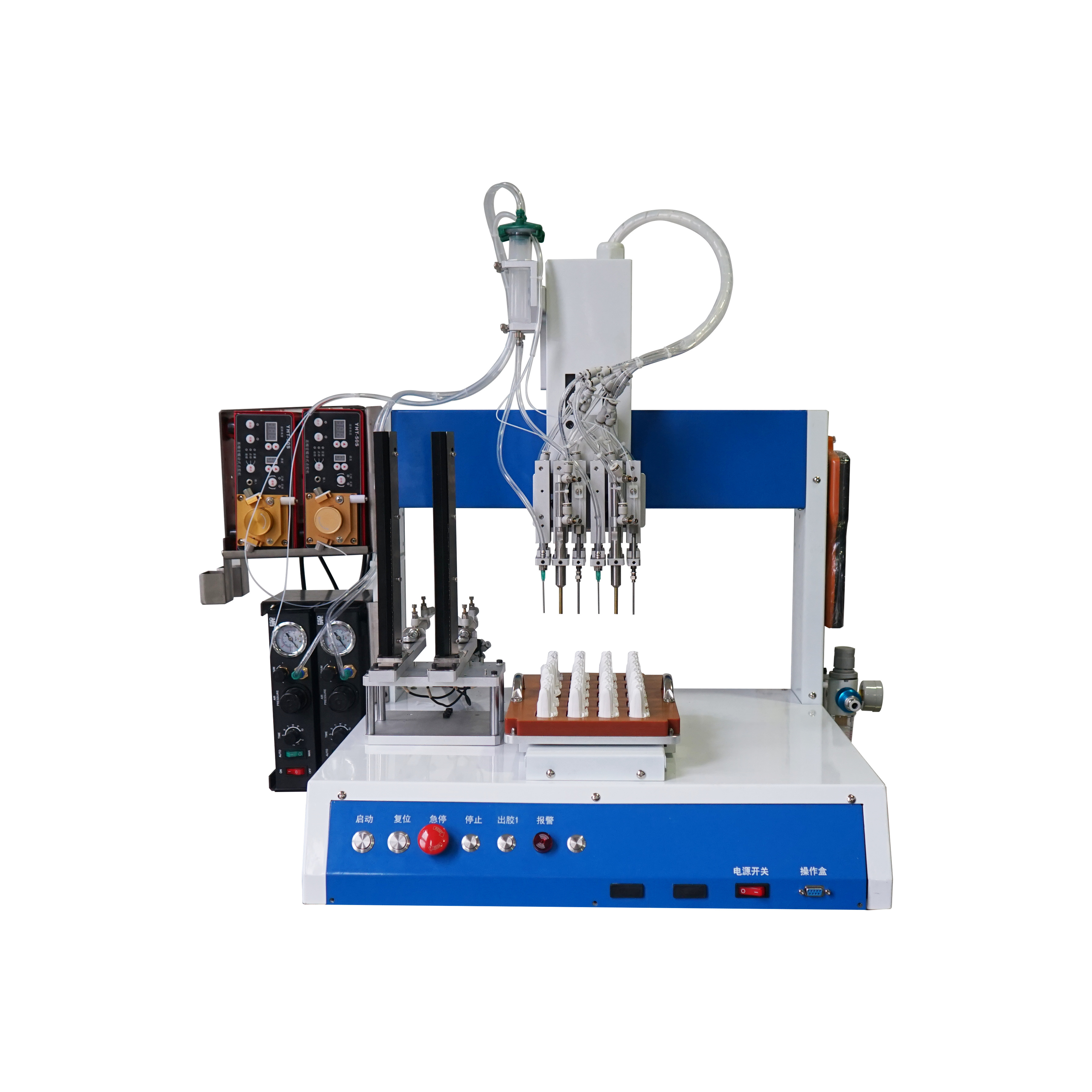

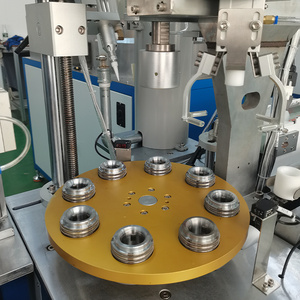

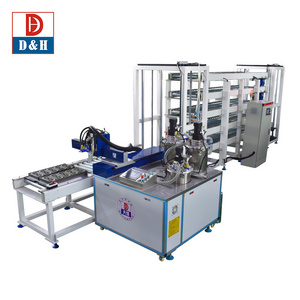

Glue dispensing and magnets assembly Automatic Machine, It is special automatic equipment which designed for the process which need glue dispensing and magnet parts assembling, and it is widely applicable for the assembling production in blue tooth headphone, electronic cigarette charging box, etc.

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Axes Range (mm):

-

300X/300Y/100Zmm

-

Work Range:

-

160X/300Y/100Zmm; @can be customized

-

Repeatability Precision:

-

±0.02mm(X/Y/Z)

-

Work Condition:

-

Temperature 0-40°C / Humidity 20-90%

-

Program record capacity:

-

9999 files, 8000 pints per file

-

Moving speed (mm / sec):

-

0.1-800

-

Magnet parts supplying system:

-

Special magnet parts feeder

-

Voltage:

-

AC110V/220V, 50/60Hz

-

Air pressure:

-

0.4-0.6MPA(4~6kg cm2)

-

Dimension (L*W*H) (mm):

-

480*500*725mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

COBBE

-

Weight (KG):

-

50

-

Marketing Type:

-

Hot Product 2023

-

Axes Range (mm):

-

300X/300Y/100Zmm

-

Work Range:

-

160X/300Y/100Zmm; @can be customized

-

Repeatability Precision:

-

±0.02mm(X/Y/Z)

-

Work Condition:

-

Temperature 0-40°C / Humidity 20-90%

-

Program record capacity:

-

9999 files, 8000 pints per file

-

Moving speed (mm / sec):

-

0.1-800

-

Magnet parts supplying system:

-

Special magnet parts feeder

-

Voltage:

-

AC110V/220V, 50/60Hz

-

Air pressure:

-

0.4-0.6MPA(4~6kg cm2)

-

Dimension (L*W*H) (mm):

-

480*500*725mm

Products Display

Product Description

Features

1)With functions of drawing points, lines, surfaces, arc, circle and consecutive interpolation of irregular curves to realize any 3D non planar trajectory path.

2)The size of glue, speed of glue spread, dispensing time, time of halting dispensing can be set by parameters.

3)The glue outflow is quiet stable, without leaking and dripping.

4)Excellent teaching function to support array, graphical browsing, three dimensional elliptic, common graphical library inserting, group editing and so on.

5)Equipped with 2 kinds of dispensing system, it can be selected to dispense by 2 kinds of different glue at the same or only selected one.

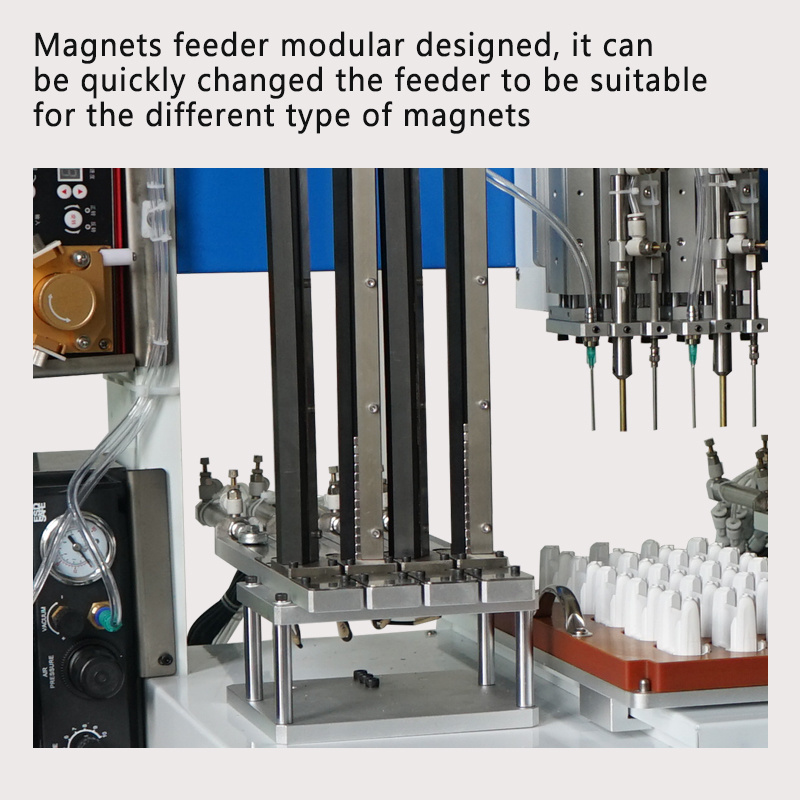

6)It is very flexible for the magnets parts feeding system, it can be supplied 1~4 same mode magnets parts at same time, also can be supplied 1~4 different mode magnets parts at same time.

7)The magnet parts feeder is designed by modules, it is very convenience to change by what you want.

8)Double dispensing heads design, efficiency is increased 2 times.

9)With the function of programming of parameter copy, position correct, position copy, array, batch editing and modification, as well as other fast editing function, can greatly improve editing efficiency and can be easily to operator.

10)Accuracy of ±0.02mm ensures the accuracy of the position during production.

Specification

|

Product Name

|

Glue dispensing and magnets parts assembly Automatic Machine

|

|

|

|

Mode

|

CBCT-331 IIC

|

CBCT-441 IIC

|

|

|

Axis range

|

300X/300Y/100Zmm

|

400X/400Y/100Zmm

|

|

|

|

@Can be customized

|

|

|

|

Work range

|

160X/300Y/100Zmm

|

260X/400Y/100Zmm

|

|

|

Number of Axes

|

3 Axes

|

|

|

|

Number of platform

|

1 sets

|

|

|

|

Number of dispensing head

|

4 sets

|

|

|

|

Number of head of suction magnet parts

|

1~3 sets

|

|

|

|

Moving speed(mm/second)

|

0~800

|

|

|

|

Repeatability precision

|

±0.02mm/(X/Y/Z)

|

|

|

|

Display mode

|

LCD teaching box

|

|

|

|

Motor system

|

precision micro stepping motor

|

|

|

|

Driving mode

|

Precision stepper motor + precision rail + precision belt

|

|

|

|

|

@(optional closed-loop stepper motor)

|

|

|

|

Control system

|

Special controller for dispensing and magnet parts assembling

|

|

|

|

Magnet parts feeding mode

|

Special magnet parts automatic feeder

|

|

|

|

Voltage

|

AC110/220V, 50/60Hz

|

|

|

|

Maximum load weight

|

15kg for work platform

|

|

|

|

Programming file capacity

|

256MB, up to 9999 files, single file up to 8000 points

|

|

|

|

Magnet parts feeding control

|

Air-operated

|

|

|

|

Air pressure

|

0.4 to 0.6MPa(4~6kg cm2) as dry air

|

|

|

|

Working temperature

|

0-40℃

|

|

|

|

Working humidity

|

20-90%

|

|

|

|

External dimensions(L*W*H)

|

480*500*725mm

|

580*600*725mm

|

|

|

Net weight

|

50kg

|

60kg

|

|

Main Products

Hot Searches