- Product Details

- {{item.text}}

Quick Details

-

Air Consumption:

-

12m3/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SINOGROUT

-

Voltage:

-

220V/380V/400V/415V/440V/660V 50Hz/60Hz, 220V/380V/400V/415V/440V/660V 50Hz/60Hz

-

Power:

-

5.5 KW

-

Dimension(L*W*H):

-

1700*900*1150mm

-

Weight:

-

850 kg

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Electric dry Shotcrete Concrete spraying machine price

-

Drive mode:

-

Electric motor

-

Operating air pressure:

-

0.2-0.4Mpa

-

Other drive mode:

-

Diesel engine or Air motor drive is available

-

Wet shotcrete machine:

-

Available

-

Service life of steel rotor plate:

-

3000sq meter

-

Service life of sealing plate:

-

800sq meter

-

Application:

-

slope stabilization,basement walls,concrete repair,etc.

Quick Details

-

Max. Conveying Distance:

-

Horizontal:200m Vertical: 20m

-

Max Aggregate Size:

-

20mm

-

Hose Inner Diameter:

-

51 mm

-

Air Consumption:

-

12m3/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SINOGROUT

-

Voltage:

-

220V/380V/400V/415V/440V/660V 50Hz/60Hz, 220V/380V/400V/415V/440V/660V 50Hz/60Hz

-

Power:

-

5.5 KW

-

Dimension(L*W*H):

-

1700*900*1150mm

-

Weight:

-

850 kg

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Electric dry Shotcrete Concrete spraying machine price

-

Drive mode:

-

Electric motor

-

Operating air pressure:

-

0.2-0.4Mpa

-

Other drive mode:

-

Diesel engine or Air motor drive is available

-

Wet shotcrete machine:

-

Available

-

Service life of steel rotor plate:

-

3000sq meter

-

Service life of sealing plate:

-

800sq meter

-

Application:

-

slope stabilization,basement walls,concrete repair,etc.

Products Description

The SPZ series concrete shotcrete machine are an anchor shotcrete support equipment for shotcrete,the features are well-structured,Perfect and stable performance. Easy to apply and maintain and durable.It’s good at mine,tunnel,culvert,subway,slope support,hydropower engineering underground engineering and shotcrete construction of coal mine high gas mine roadway.

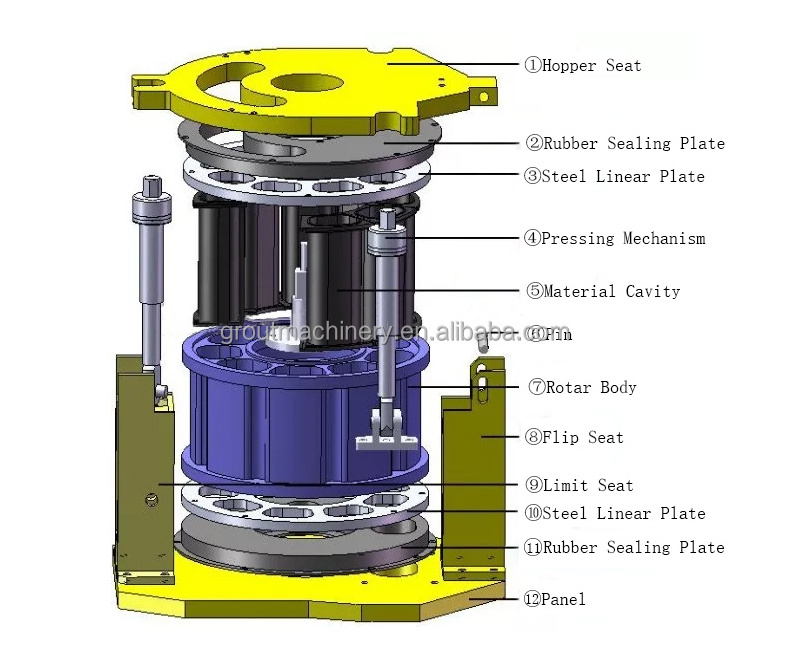

The working principle of the SPZ series concrete shotcrete machine:

The SPZ series concrete shotcrete machine is mainly composed by the driving device, rotorassembly , Airway system,injection system,electrical control box. Mixed materials are discharged from the mixer into the shotcrete vibrating screen mesh feeding hopper,Injected into the rotor body through the feeder then to the outlet,compressed air is introduced from the air chamber to blow the material into the discharge elbow,at same time another compressed air is introduced by the cyclone,the material is blown away in a multi-headed wind spiral state accelerate, and output rotation, float,to the material pipe,Then,add some water or liquid accelerator and spray it out.

Technical Parameters

|

Dry Shotcrete Machine

|

|

|

|

|||

|

Model

|

SPZ-3

|

SPZ-5

|

SPZ-7

|

|||

|

Spray Capacity

|

3m³/h

|

5m³/h

|

7m³/h

|

|||

|

Horizontal

|

200m

|

200m

|

200m

|

|||

|

Vertical

|

20m

|

20m

|

20m

|

|||

|

Water Cement Ratio

|

<0.4

|

<0.4

|

<0.4

|

|||

|

Max. Aggregate Size

|

Ø20mm

|

Ø20mm

|

Ø20mm

|

|||

|

Operating Air Pressure

|

0.4-0.6mpa

|

0.4-0.6mpa

|

0.6-0.8mpa

|

|||

|

Air Consumption

|

3-4m³/min

|

6-8m³/min

|

12m³/min

|

|||

|

Power

|

3kw

|

5.5kw

|

7.5kw

|

|||

|

Size

|

1040*550*950mm

|

1300*705*1300mm

|

1700*900*1150mm

|

|||

|

Weight

|

260kg

|

600kg

|

850kg

|

|||

Features of dry shotcrete machine

1.Through-rotor,Smooth discharge,efficiency.

2.Four-point elastic Compensation Compression,good sealing effect,less dust,Wearing parts reinforce.

3.Low-pressure high-speed vortex air transport,overcome sticking in material conveying,plugging and pulse distraction.The material flow is uniform, continuous and stable.

4.New nozzle,outlet elbow device,improve spray effect,less rebound,high quality spray layer.

5.The shotcrete chassis can be assembled into a tire type,skid type and rail wheel type of various gauges

2.Four-point elastic Compensation Compression,good sealing effect,less dust,Wearing parts reinforce.

3.Low-pressure high-speed vortex air transport,overcome sticking in material conveying,plugging and pulse distraction.The material flow is uniform, continuous and stable.

4.New nozzle,outlet elbow device,improve spray effect,less rebound,high quality spray layer.

5.The shotcrete chassis can be assembled into a tire type,skid type and rail wheel type of various gauges

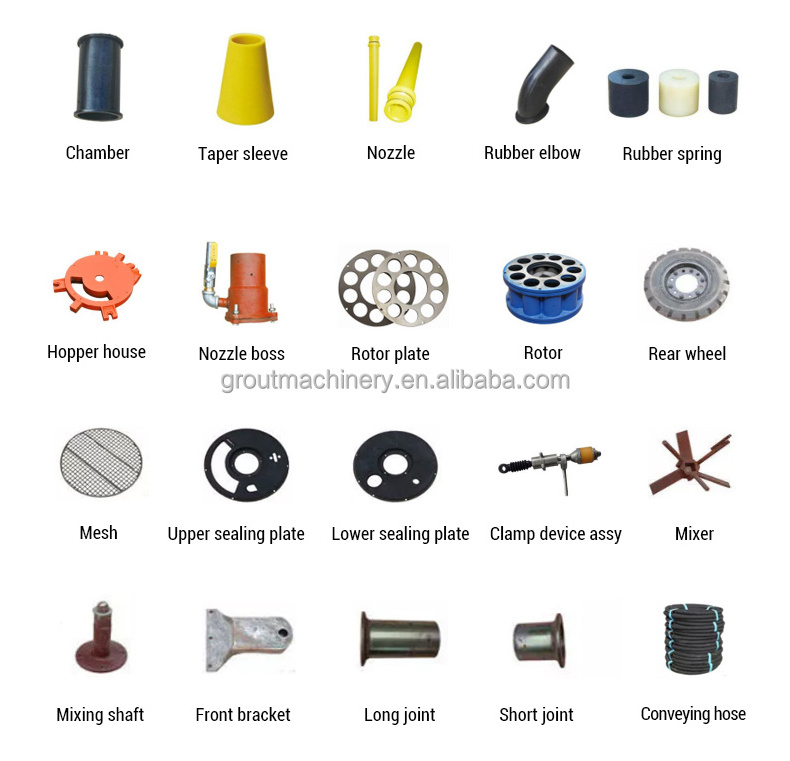

Details Images

Application

Pictures of the

dry shotcrete machine

Related Products

Factory Show

Hot Searches