- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Sure

-

Dimension(L*W*H):

-

4.0*3.3*2.1m

-

Weight:

-

3000 KG

-

Product name:

-

Spiral Freezer SF200

-

Capacity:

-

200kg/h

-

Application:

-

Food Quick Frozen Machine

-

Inlet /outlet Temperature:

-

+15 degree Celsius /-18 degree Celsius

-

Refrigerant:

-

R404A

-

Freezer Type:

-

Air cooled

-

Refrigeration Capacity:

-

37.22 KW (+40 degree C/-40 degree C)

-

Compressor Model:

-

BITZER S6H-20.2Y 2-stage*2 sets

-

Evaporating Area:

-

360 square meters

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

36.0 kw

-

Cooling Capacity:

-

200kg/h

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Sure

-

Dimension(L*W*H):

-

4.0*3.3*2.1m

-

Weight:

-

3000 KG

-

Product name:

-

Spiral Freezer SF200

-

Capacity:

-

200kg/h

-

Application:

-

Food Quick Frozen Machine

-

Inlet /outlet Temperature:

-

+15 degree Celsius /-18 degree Celsius

-

Refrigerant:

-

R404A

-

Freezer Type:

-

Air cooled

-

Refrigeration Capacity:

-

37.22 KW (+40 degree C/-40 degree C)

-

Compressor Model:

-

BITZER S6H-20.2Y 2-stage*2 sets

-

Evaporating Area:

-

360 square meters

-

Marketing Type:

-

Ordinary Product

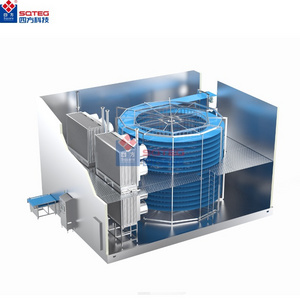

Product Application:

Sprial freezers are mostly used for flour food freezing,meat freezing,seafood freezing,and prepared food freezing .

Main fetures:

Thoroughly sanitary freezing environment

1 According to HACCP sanitary safety concept, the inner is designed for simple cleaning and maintenance, fully conforming to food sanitary requirements.

2 The internal body and mesh belt are made of stainless steel SUS304.

3 With hydrophilic film, the fins of heat exchanger can be avoided from harmful powder of alumina.

4 All roller wheel, turn hub,and guideway are made of sanitary ultra-high molecular weight polyethylene.

Advantages:

1 Arc air deflector, uniform inner temperature and efficient working capacity;

2 Fined type evaporator, exchanging heat efficiently and cooling down quickly keep reliable and stable;

3 Advanced design in guarantee stable running;

4 Strict manufacture installation to ensure accuracy and reliability;

5 Multiple alarm system to eliminate incipient fault .

Main component:

1. Stainless steel conveyor belt:

The conveyor belt is made of food grade stainless steel. The surface of belt is flat and neat. There are baffle edges on both sides of belt, which can prevent the products from dropping down.

2.Insulation panels:

PUF sandwich panels, 150mm thick with 42kg/m3 density, laminated both sides by stainless steel sheet.

3.Door:

Equipped with double seals and frame heating system

4.Inner structure:

The drum is designed in squirrel cage structure, and the components on which touching with conveyor belt are in arc shape. We inlaid the column bar of drum with UHMW-PE (ultra high molecular weight polyethylene) materials which have a good wear-resistance performance.

5.Driving device:

Speed reducer + Variable speed controller

6.Evaporator and fan:

Both the fins and tubes are made of aluminum alloy. The frame structure of evaporator is made of food grade stainless steel. The air-box of axial fan is made of food grade stainless steel while the fan blades are made of aluminum alloy.

7.Belt tension device:

We adopt floating axle weight as belt tension device. The tension degree of conveyor belt can be adjusted.

8.Water slot (water plate) and drainage design:

The water slot will be installed on top of floor panels. It is made of food grade stainless steel. The water slot has proper slope to facilitate water discharging and avoid defrosting water penetrating into the floor panels.

9.Inlet device and outlet device:

Both the inlet device and outlet device are made of food grade stainless steel.

10.Control panel:

We adopt Schneider or Siemens electrical components.

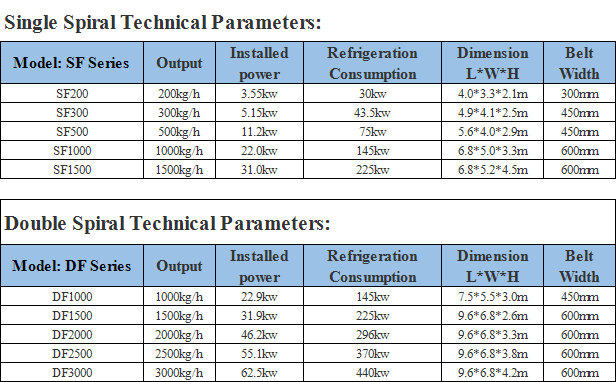

Main technology parameters of spiral freezer as below:

| NO. | ITEM | CONTENT |

| 1 | Equipment Type | Spiral Freezer SF200 |

| 2 | Belt Material | Food grade stainless steel |

| 3 | Output Capacity | 200kg/h |

| 4 | Inlet Temperature | +15 degree Celsius |

| 5 | Outlet Temperature | -18 degree Celsius |

| 6 | Inner Temperature | -38±3 degree Celsius |

| 7 | Cabinet Dimension | 4000mm*3300mm*2100mm L*W*H |

| 8 | Qty of Tiers | 9 tiers |

| 9 | Drum Diameter | 1260mm |

| 10 | Tier Pitch | 125mm, 65mm effective |

| 11 | Refrigeration Consumption | 36KW (+40 degree C/-40 degree C) |

| 12 | Evaporating Area | 360 square meters |

| 13 | Compressor Model | BITZER S6H-20.2Y 2-stage*2 sets |

| 14 | Refrigeration Capacity | 37.22 KW (+40 degree C/-40 degree C) |

| 15 | Refrigerant | R404a |

| 16 | Condensing Type | Air cooled |

| 17 | Installed Power for Spiral Freezer | 3.55 KW |

| 18 | Installed Power for Compressor Unit | 33.6KW |