- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHIYUE

-

Voltage:

-

customer local voltage

-

Dimension(L*W*H):

-

7400*1950*2800mm

-

Weight (KG):

-

5000 kg

-

rate pressure:

-

16Mpa

-

Main vibration form:

-

Platform Vibration

-

Vibration frequency:

-

4600r/min

-

Molding cycle:

-

15-20 seconds

-

overall power:

-

36kw

-

voltage:

-

according to customer local voltage

-

Color:

-

according to your request

-

Pallet size:

-

1100*550mm

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other

-

Brick Raw Material:

-

Cement,Concrete

-

Production Capacity (Pieces/8 hours):

-

Other, 4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 7200-70400 pcs per 8 hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHIYUE

-

Voltage:

-

customer local voltage

-

Dimension(L*W*H):

-

7400*1950*2800mm

-

Weight (KG):

-

5000 kg

-

rate pressure:

-

16Mpa

-

Main vibration form:

-

Platform Vibration

-

Vibration frequency:

-

4600r/min

-

Molding cycle:

-

15-20 seconds

-

overall power:

-

36kw

-

voltage:

-

according to customer local voltage

-

Color:

-

according to your request

-

Pallet size:

-

1100*550mm

Main technical parameters

|

Overall Dimension

|

7400*1950*2800mm

|

|

vibration frequency

|

0-60HZ

|

|

Vibration Form

|

Platform Vibration

|

|

moulding mode

|

load automatically,vibration moulding

|

|

Pallet Size

|

1100x550mm

|

|

Molding cycle

|

15-20s

|

|

Overall Power

|

32 KW

|

|

Vibration Force

|

80 KN

|

|

Total Mass

|

5000kgs

|

|

Demolding method

|

Hydraulic

|

|

Factory Area

|

1000m2

|

Products Description

1.This machine can use flyash, slag, gangue and other kind industrial residue then with sand, water, crushed stone, cement all kind material to make all kind hollow block, paver brick, solid bricks just changing the moulds. And the percentage of the flyash can reach 70%.

2.The whole process of this machine is controlled by PLC and powered by the hydraulic system. Monitoring with the approach switch, machinery, electric, hydraulic and vibrating system work together to make pallets feeding, material feeding, vibrating, demoulding process work automatically. And its characteristic is high efficient, easy-operated and easy-maintained.

3.All the electrical and hydraulic parts are original imported or with China famous brand. So this machine is stable and with less faults. Also it is can be used many years and easy to maintaining.

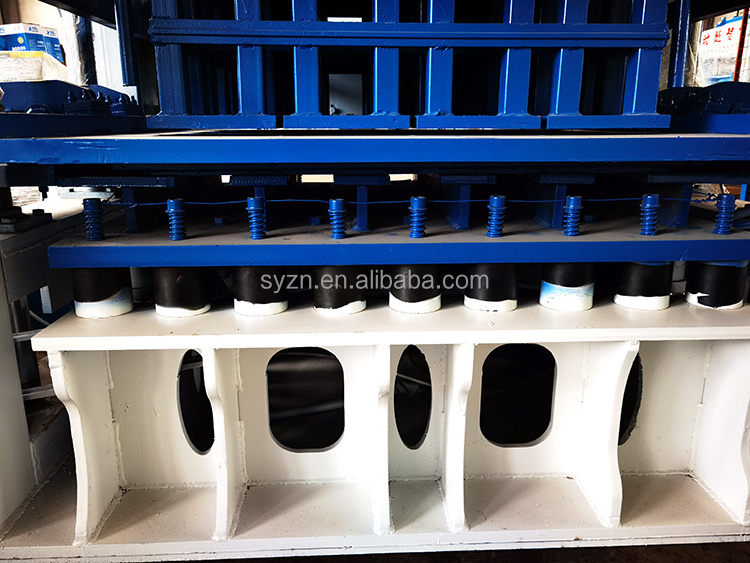

4.Block molding mainly by hydraulic, machinery as sideline, vibrate and press to finish molding blocks. Our machine is assembled with our own patent vibrating system and with high power and frequency.

5.The compressive strength of all blocks more than 15 MPa, compactness is high, impermeability and freeze resistance is better, and excellent capacity of sound insulation, heat insulation and dimensions are precise, the blocks are more consistency and low waster rate.

6.Moulds system is working synchronized and can ensure the products with same thickness and stable.

7.Products come out together then can be stacked efficient and cut off the power consumption and the labour cost.

8. This machine is specially for making standard solid bricks and is the better option for environmental protection and construction equipments.

Electronically controlled intelligent

Automatic process of selection of foreign advanced PLC (Programmable Logic Controller) intelligent control, with products process data input, storage, touch screen, ideal, flexible interactive interface. Imports of electrical and hydraulic components and essentially trouble-free operation, random testing of advanced control systems for remote control of the two systems, fault diagnosis.

Hydraulic system reliability

Preferred technique, well-made hydraulic parts, supporting reasonable hydraulic system, design using independent integrated hydraulic station, avoid the host vibration, dust influence hydraulic system, in order to ensure the reliability of the hydraulic system.

Block machine with strong adaptability

The vertical station mode resonance, automatic FM-AM, and realize the "more function with one machine", through the simple replacement of the mold, the products can quickly adjust production, the maximum extent to meet the market demand, so that the equipment maximize performance.

Component of block machine and function

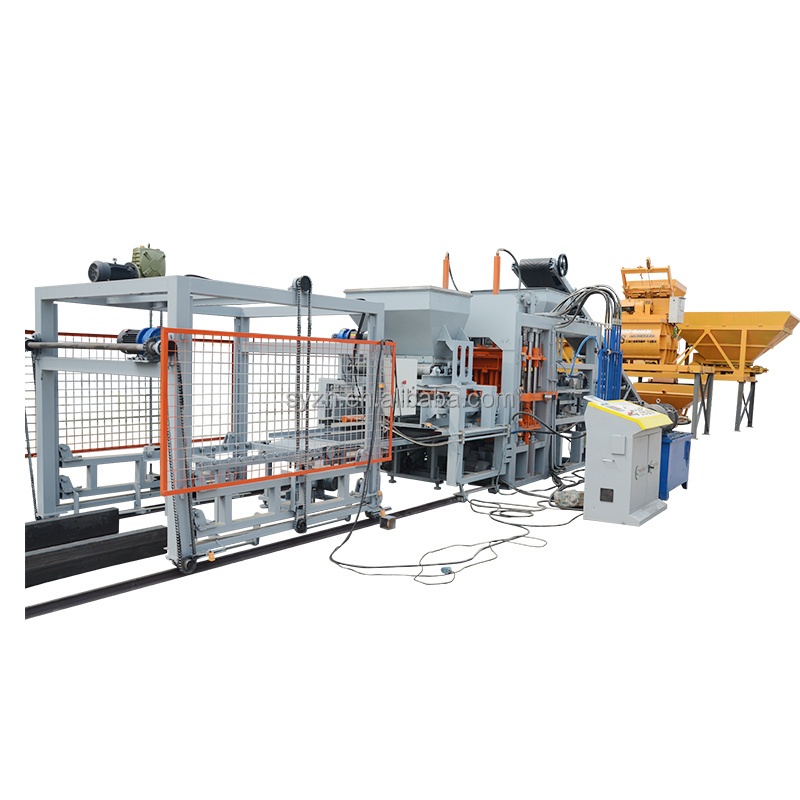

Block machine is consisted of: pallet feed machine, block making machine, storage hopper, conveyor, hydraulic unit, PLC control cabinet

Common blocks theoretical Capacity and common blocks samples

|

Type

|

Size

(mm) |

Molding cycle

|

Qty/Mould

(pcs) |

Qty/hour

(pcs) |

Qty/8hr

(pcs) |

|

Hollow block

|

400x200x200

|

15-20s

|

5

|

900-1200

|

7200-9600

|

|

Hollow block

|

400x150x200

|

15-20s

|

6

|

1080-1440

|

8640-11520

|

|

Solid brick

|

240x115x53

|

15-20s

|

32

|

5760-7680

|

46080-61440

|

|

Rectangular brick

|

200x100x60

|

20-25s

|

25

|

3600-4500

|

28800-36000

|

|

Zigzag brick

|

225x112.5x60

|

20-25s

|

16

|

2304-2880

|

18432-23040

|

Packaging And Shipping

Customer Visiting and customer working site

Hot Searches