- Product Details

- {{item.text}}

Quick Details

-

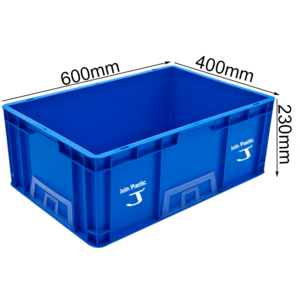

Capacity:

-

500-2000kg

-

Product name:

-

turnover box

-

Material:

-

Steel Q235

-

Color:

-

Standard blue color, can be customized

-

Outer size:

-

1200*1000*897mm, or customized

-

Inner size:

-

1080*900*700mm

-

Iron plate thickness:

-

1.2mm

-

Bottom square tube size:

-

40*40*1.5mm

-

Upright square tube size:

-

40*40*2mm

-

Static load:

-

1000kg, or customized

-

Surface finish:

-

powder coating

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KINGMORE

-

Model Number:

-

KM-18

-

Capacity:

-

500-2000kg

-

Product name:

-

turnover box

-

Material:

-

Steel Q235

-

Color:

-

Standard blue color, can be customized

-

Outer size:

-

1200*1000*897mm, or customized

-

Inner size:

-

1080*900*700mm

-

Iron plate thickness:

-

1.2mm

-

Bottom square tube size:

-

40*40*1.5mm

-

Upright square tube size:

-

40*40*2mm

-

Static load:

-

1000kg, or customized

-

Surface finish:

-

powder coating

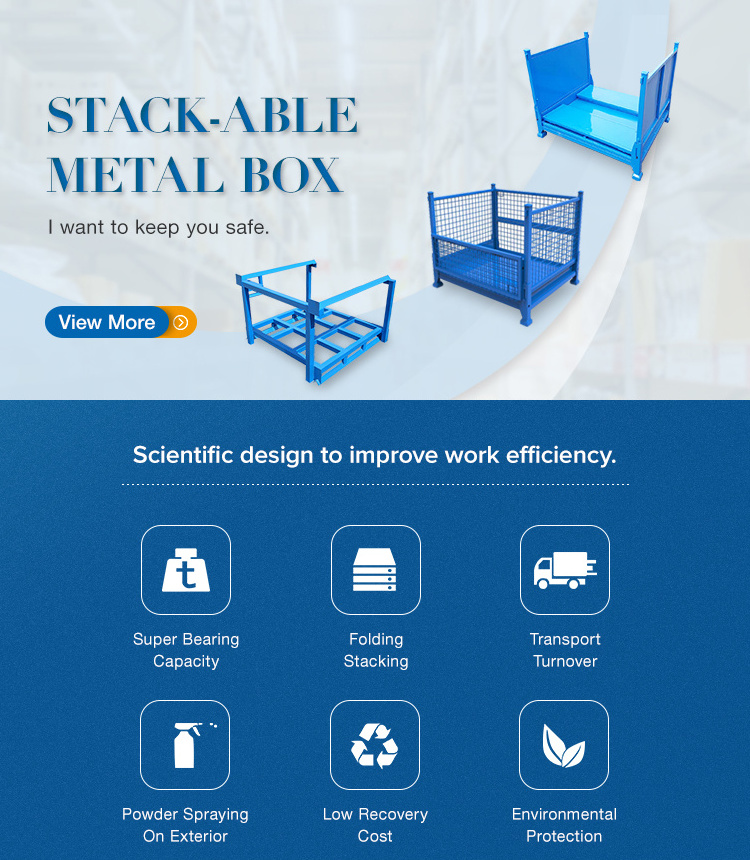

Industrial metal storage cage stackable warehouse turnover boxes with strong carrying capacity

|

Name |

Industrial metal storage cage stackable warehouse turnover boxes with strong carrying capacity |

|

Outer size |

1200*1000*897mm, or customized |

|

Inner size |

1080*900*700mm |

|

Iron plate thickness |

1.2mm |

|

Bottom square tube size |

40*40*1.5mm |

|

Upright square tube size |

40*40*2mm |

|

Material |

Q235 |

|

Static load |

1000kg, or customized |

|

Surface treatment |

powder coating |

|

Surface color |

blue or customized |

Specifications of stack-able metal box

The material box is also called turnover box or reinforced storage cage. It mainly bears some heavy duty products, could be fold-able and stack-able to effectively use the storage space. It also features low recycling costs.

Material box is widely used in manufacturing-type processing enterprises, product warehouse, logistics storage centers and other occasions. They are an important part of modern logistics storage equipment. The material box has various structural forms, convenient and flexible use, and strong carrying capacity. The bins can usually be stacked on top of each other, or can be matched with a forklift to flow in the area, casters can be installed at the bottom, and it can be lifted, shifted and dropped with the crane.

The bottom of the material box adopts a frame-type rigid structure, which is welded by a steel panel and steel legs. The bottom frame is usually made of rectangular and square tubes by welding. The columns are generally square tubes, and the surrounding is made of high-quality steel and rectangular tubes. The surface treatment of the bin adopts shot blasting technology, which can better remove rust and oil, eliminate the problem of sewage pollution caused by the previous pickling and phosphating, and meet the environmental protection requirements, which is beneficial to the export of steel bins. In the later period, high temperature spray baking technology is used to make the product look neat, beautiful and durable.