- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

high

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

senke

-

Voltage:

-

380V/415V/440V

-

Dimension(L*W*H):

-

4000*1500*3100

-

Weight:

-

8000 kg

-

Warranty of core components:

-

Other

-

Product name:

-

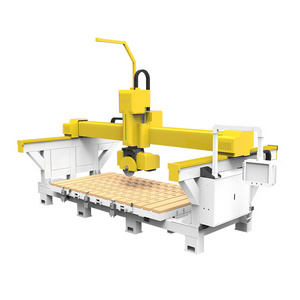

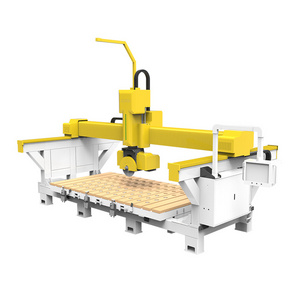

Bridge Saw Cnc Stone Cutting Machine

-

Function:

-

Stone Engraving Carving Cutting

-

Application:

-

Stone Marble Granite Quartz Sandstone

-

Control system:

-

NC Studio

-

Feature:

-

5 Axis Cnc Stone Carving Machine

-

Color:

-

Customer Needing

-

Description:

-

Cnc Bridge Stone Cutting Machine

-

Advantage:

-

High Efficent

-

Max Cutting Length:

-

4800mm

-

Blade diameter:

-

400-700mm

Quick Details

-

Type:

-

Stone Cutting Machine

-

Power:

-

120KW

-

Cutting thickness (max):

-

10.5mm

-

Production Capacity:

-

high

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

senke

-

Voltage:

-

380V/415V/440V

-

Dimension(L*W*H):

-

4000*1500*3100

-

Weight:

-

8000 kg

-

Warranty of core components:

-

Other

-

Product name:

-

Bridge Saw Cnc Stone Cutting Machine

-

Function:

-

Stone Engraving Carving Cutting

-

Application:

-

Stone Marble Granite Quartz Sandstone

-

Control system:

-

NC Studio

-

Feature:

-

5 Axis Cnc Stone Carving Machine

-

Color:

-

Customer Needing

-

Description:

-

Cnc Bridge Stone Cutting Machine

-

Advantage:

-

High Efficent

-

Max Cutting Length:

-

4800mm

-

Blade diameter:

-

400-700mm

Products Description

In a groundbreaking development, the stone industry has been revolutionized by the introduction of a state-of-the-art 5-axis bridge saw stone cutting machine. This cutting-edge technology promises to redefine the way stone fabrication is carried out, offering unprecedented levels of precision, efficiency, and versatility for manufacturers and artisans alike.

The 5-axis bridge saw employs cutting-edge robotic arms and advanced software algorithms to achieve intricate cuts and shapes on various types of stones, including granite, marble, and quartz. Unlike traditional 3-axis saws, which can only cut in three directions, this new machine can move its blade in two additional axes, allowing for complex, three-dimensional cuts that were once thought impossible.

One of the most significant advantages of this machine is its ability to streamline the stone fabrication process. With the inclusion of additional axes, operators can now perform multiple cuts in a single setup, drastically reducing material waste and production time. This leap in efficiency not only enhances productivity but also offers substantial cost savings for manufacturers.

The 5-axis bridge saw also introduces a level of precision that was previously unattainable. Its advanced technology enables cutting with micron-level accuracy, ensuring a seamless fit for intricate designs and reducing the need for manual adjustments. This precision enhances the overall quality of finished products, meeting even the most demanding customer specifications.

Moreover, the machine's user-friendly interface and intuitive programming make it accessible to both experienced operators and novices. The software enables users to import digital designs and convert them into precise cutting paths, simplifying the production process and eliminating potential errors.

Industry experts predict that this breakthrough technology will not only transform the manufacturing landscape but also open up new possibilities for stone artisans and designers. The 5-axis bridge saw enables them to bring their creative visions to life with unprecedented freedom, allowing for intricate artistic designs that were once constrained by the limitations of traditional cutting methods.

Environmental considerations have also been taken into account during the machine's development. By optimizing the cutting process and minimizing material wastage, the 5-axis bridge saw significantly reduces the environmental impact associated with stone fabrication.

Already, the machine has received acclaim from early adopters in the stone industry. Manufacturers have reported increased productivity, reduced lead times, and improved overall output quality, solidifying the 5-axis bridge saw's position as an indispensable asset in the modern stone fabrication facility.

As demand for customized and intricately designed stone products continues to rise, the 5-axis bridge saw is poised to become a standard tool in the stone industry. Its ability to combine precision, efficiency, and environmental consciousness marks a new era in stone fabrication, propelling the industry towards greater heights of innovation and success.

In conclusion, the introduction of the 5-axis bridge saw stone cutting machine represents a monumental advancement in the stone industry. With its ability to perform complex cuts with unprecedented precision, improve efficiency, and inspire creativity, this revolutionary technology is reshaping the way stones are crafted and pushing the boundaries of what was once thought possible in stone fabrication.

5 Axis cutting system

7.5kw water cooling spindle、Cutting saw support bevel cut

Turnover platform

1.5kw Dorna servo system

Japan Shimpo reducer

Strong heavy stable welded machine tructure body

|

Model

|

|

SKS-5 axis

|

|

|

|||

|

Working area (X*Y)

|

|

3200x2000mm

|

|

|

|||

|

Voltage

|

|

380V Three phase 50/60hz

|

|

|

|||

|

Spindle

|

|

7.5kw water cold spindle

|

|

|

|||

|

Motor power

|

|

11kw

|

|

|

|||

|

Rotate of working platform

|

|

0-80 degree

|

|

|

|||

|

Motor

|

|

1500w servo and drive

|

|

|

|||

|

Guide rail

|

|

Imported high precision 30mm guide rail transmission

|

|

|

|||

|

Reducer

|

|

Japan Shimpo high precision reducer

|

|

|

|||

|

Blade diameter

|

|

350-450mm with A axis support bevel 45 degree cutting

|

|

|

|||

|

Maximum cutting thickness

|

|

80mm

|

|

|

|||

|

Lubrication system

|

|

Auto Lubrication

|

|

|

|||

|

Infrared ray

|

|

Equipped with laser infrared probe, showing cutting path

|

|

|

|||

|

Water cooling system

|

|

Yes, Special water circulating working system

|

|

|

|||

Woking Samples

Customer Feedback

Hot Searches