2.

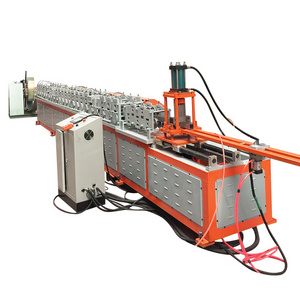

With hand wheels easy adjust for feeding different thickness raw material.

3.

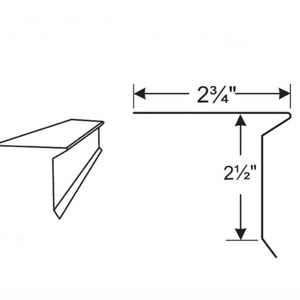

The platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.