- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

Standard

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Heating element

-

Grade:

-

Nichrome

-

Ni (Min):

-

80

-

Model Number:

-

NiCr 80/20

-

Brand Name:

-

NK

-

Certificate:

-

ROHS, ISO 9001

-

OEM:

-

Accept

-

Wire:

-

0.018mm-10.0mm

-

Ribbon:

-

0.05*0.2-2.0*6.0mm

-

Strip:

-

0.5*5.0mm-5.0*250mm

-

Condition:

-

Bright, Annealed, Soft

-

Surface Treatment:

-

Hydrogen annealing

-

Resistance tolerance:

-

±3%

-

Feature:

-

High nickel, high resistance

-

Material:

-

Fine raw material

Quick Details

-

Resistance (μΩ.m):

-

1.09

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

Standard

-

Elongation (≥ %):

-

Standard

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

Heating element

-

Grade:

-

Nichrome

-

Ni (Min):

-

80

-

Model Number:

-

NiCr 80/20

-

Brand Name:

-

NK

-

Certificate:

-

ROHS, ISO 9001

-

OEM:

-

Accept

-

Wire:

-

0.018mm-10.0mm

-

Ribbon:

-

0.05*0.2-2.0*6.0mm

-

Strip:

-

0.5*5.0mm-5.0*250mm

-

Condition:

-

Bright, Annealed, Soft

-

Surface Treatment:

-

Hydrogen annealing

-

Resistance tolerance:

-

±3%

-

Feature:

-

High nickel, high resistance

-

Material:

-

Fine raw material

Best Selling

Product Description

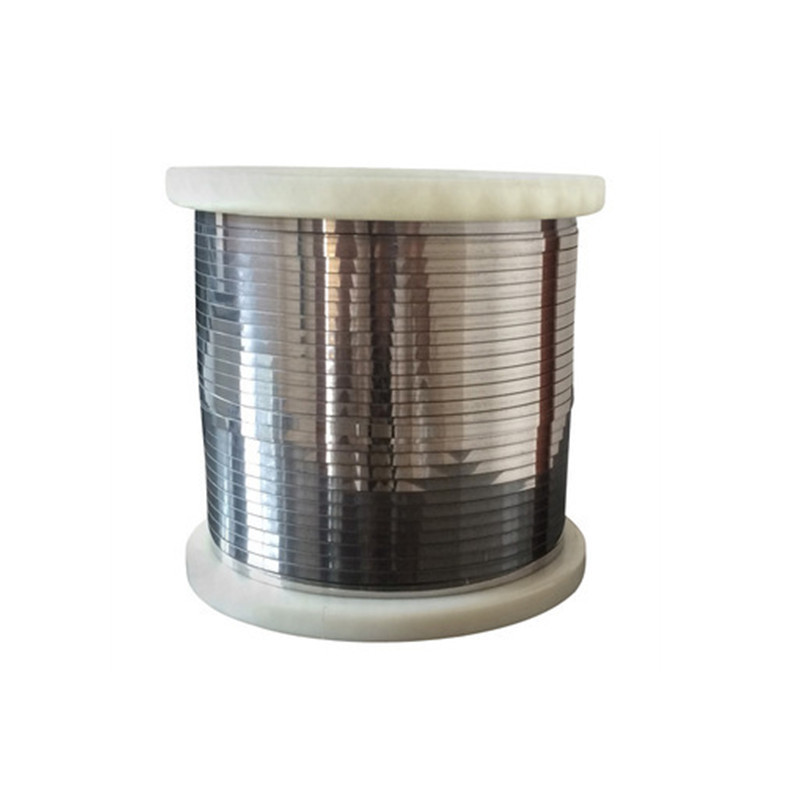

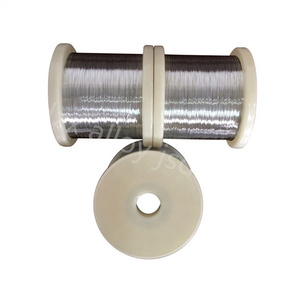

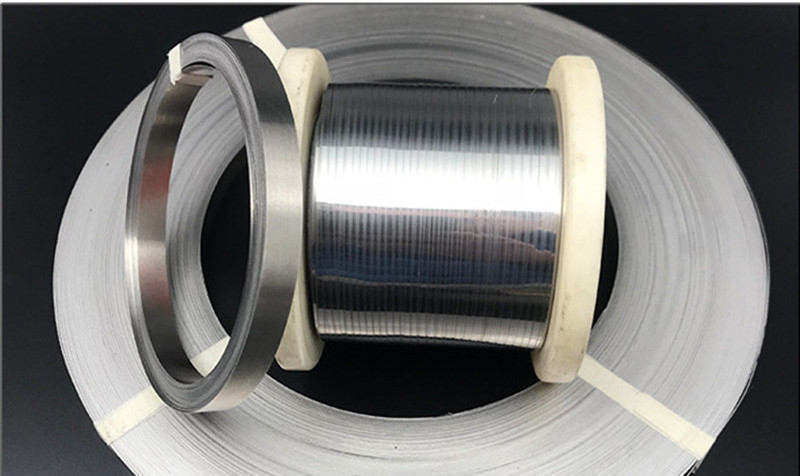

NK stable resistance ni80 3kg spool 0.45mm 25 gauge nichrome 80 20 wire

Nichrome alloy includes pure nickel, NiCr alloy, Fe-Cr-Al alloy and copper nickel alloy.

Nickel chrome alloys: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20

FeCrAl alloy: 0Cr25Al5, 0Cr23Al5, 0Cr21Al4, 0Cr27Al7Mo2, 0Cr21Al6Nb, 0Cr21Al6.

Copper nickel alloy: CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi23, CuNi30, CuNi44, Constantan,CuMn12Ni

Our Nichrome alloy are

in the form of

round wire, flat wire, coil, strip

.

Nichrome Grade:

Ni80Cr20, Ni90Cr10, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20

80/20 Nichrome wire

is a non magnetic alloy with a high melting point and corrosion resistance. Because of its good workability

and high temperature strength, It is widely used for heavy duty applications in the electric appliance industry.

and high temperature strength, It is widely used for heavy duty applications in the electric appliance industry.

Nichrome wire sizes are:

Wire: 0.018mm-10mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

Bar: 10-100m

Wire: 0.018mm-10mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

Bar: 10-100m

Composition and Main Properties of Nichrome Alloy

|

Alloy Nomenclature Performance

|

|

Cr20Ni80

|

Cr30Ni70

|

Cr15Ni60

|

Cr20Ni35

|

Cr20Ni30

|

|

|

Main composition

|

Ni

|

Rest

|

Rest

|

55.0-61.0

|

34.0-37.0

|

30.0-34.0

|

|

|

|

Cr

|

20.0-23.0

|

28.0-31.0

|

15.0-18.0

|

18.0-21.0

|

18.0-21.0

|

|

|

|

Fe

|

≤1.0

|

≤1.0

|

Rest

|

Rest

|

Rest

|

|

|

Max. continuous service temp. of element(ºC)

|

|

1200

|

1250

|

1150

|

1100

|

1100

|

|

|

Resistivity at 20ºC (μΩ·m)

|

|

1.09

|

1.18

|

1.12

|

1.0

|

1.04

|

|

|

Density(g/cm3)

|

|

8.40

|

8.10

|

8.20

|

7.90

|

7.90

|

|

|

Thermal conductivity (KJ/m·h·ºC)

|

|

60.3

|

45.2

|

45.2

|

43.8

|

43.8

|

|

|

Coefficient of lines expansion(α×10-6/ºC)

|

|

18.0

|

17.0

|

17.0

|

19.0

|

19.0

|

|

|

Melting point approx.( ºC)

|

|

1400

|

1380

|

1390

|

1390

|

1390

|

|

|

Elongation at rupture(%)

|

|

>20

|

>20

|

>20

|

>20

|

>20

|

|

|

Micrographic structure

|

|

austenite

|

austenite

|

austenite

|

austenite

|

austenite

|

|

|

Magnetic properties

|

|

nonmagnetic

|

nonmagnetic

|

Weak magnetic

|

Weak magnetic

|

Weak magnetic

|

|

Application

Application of nichrome alloy wire

A Resistance Alloy used in electrical heating application. It is recommended for use in dry air applications up to 2150 degrees F with good hot strength. It is an alloy of nickel and chromium with high electrical resistance; used for resistance heating elements. Nichrome 80/20 is an ideal material, because it has relatively high resistance and forms an adherent layer of chromium oxide when it is heated for the first time. Material beneath the wire will not oxidize, preventing the wire from breaking or burning out.

* These elements are commonly found in precision heating applications such as Medical Diagnostics, Satellite, and Aerospace

* Electrical appliance industry

* Ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular elements, cartridge elements

A Resistance Alloy used in electrical heating application. It is recommended for use in dry air applications up to 2150 degrees F with good hot strength. It is an alloy of nickel and chromium with high electrical resistance; used for resistance heating elements. Nichrome 80/20 is an ideal material, because it has relatively high resistance and forms an adherent layer of chromium oxide when it is heated for the first time. Material beneath the wire will not oxidize, preventing the wire from breaking or burning out.

Applications:

* These elements are commonly found in precision heating applications such as Medical Diagnostics, Satellite, and Aerospace

* Electrical appliance industry

* Ironing machines, water heaters, plastic moulding dies, soldering irons, metal sheathed tubular elements, cartridge elements

Related Products

Nichrome 80 20 wire 30ft/spool

Nichrome 70 wire 30ft/spool

Nichrome 90 wire 30ft/spool

NiFe 30 wire 30ft/spool

A1 wire 30ft/spool

Hot Searches