- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CCJ-13

-

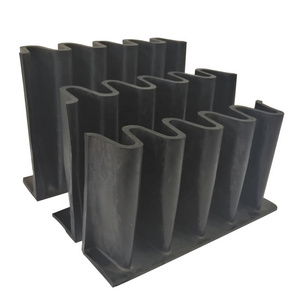

Product Name:

-

Side Wall Rubber Conveyor Belt

-

Length:

-

Customer's Option

-

Material:

-

Fabric and rubber

-

Color:

-

Black

-

Size:

-

Customized Size

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

CCJ

-

Model Number:

-

CCJ-13

-

Product Name:

-

Side Wall Rubber Conveyor Belt

-

Length:

-

Customer's Option

-

Material:

-

Fabric and rubber

-

Color:

-

Black

-

Size:

-

Customized Size

Other Recommendations for Your Business

Product Description

|

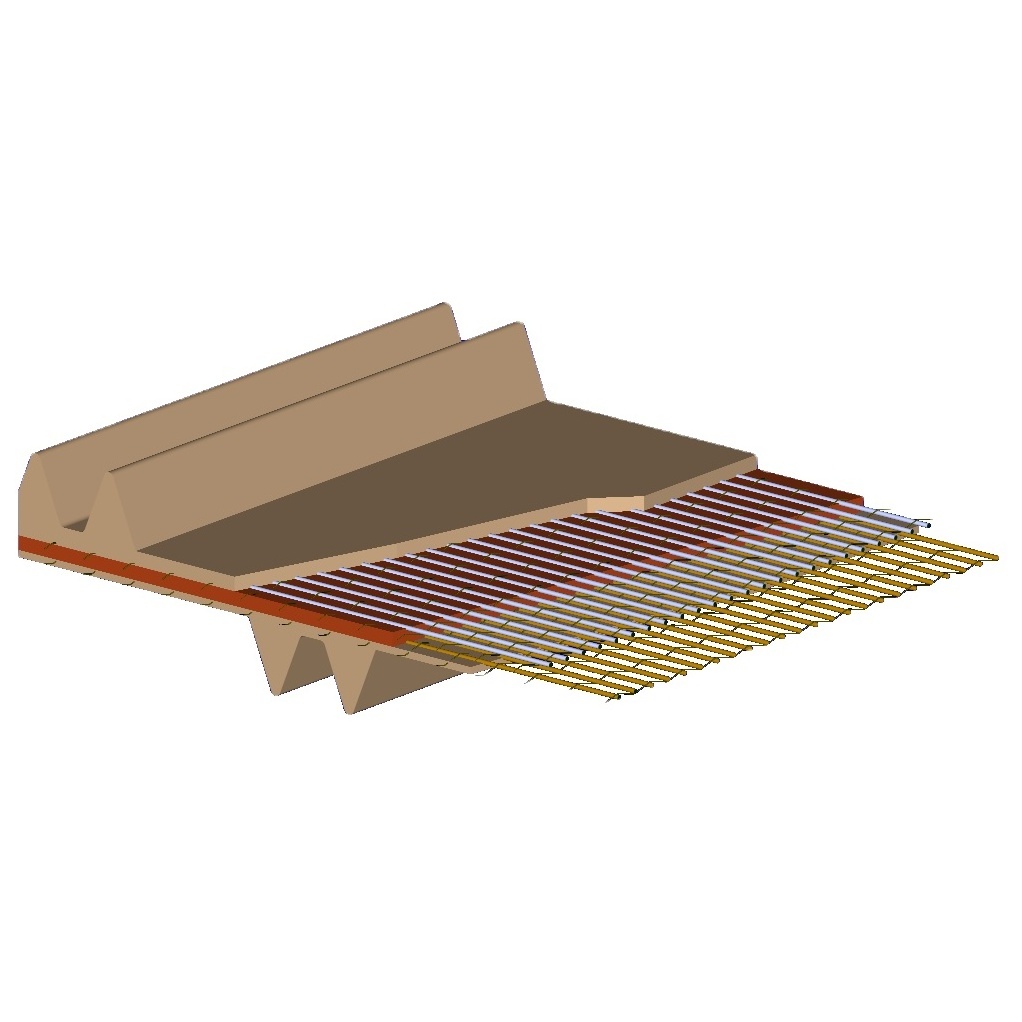

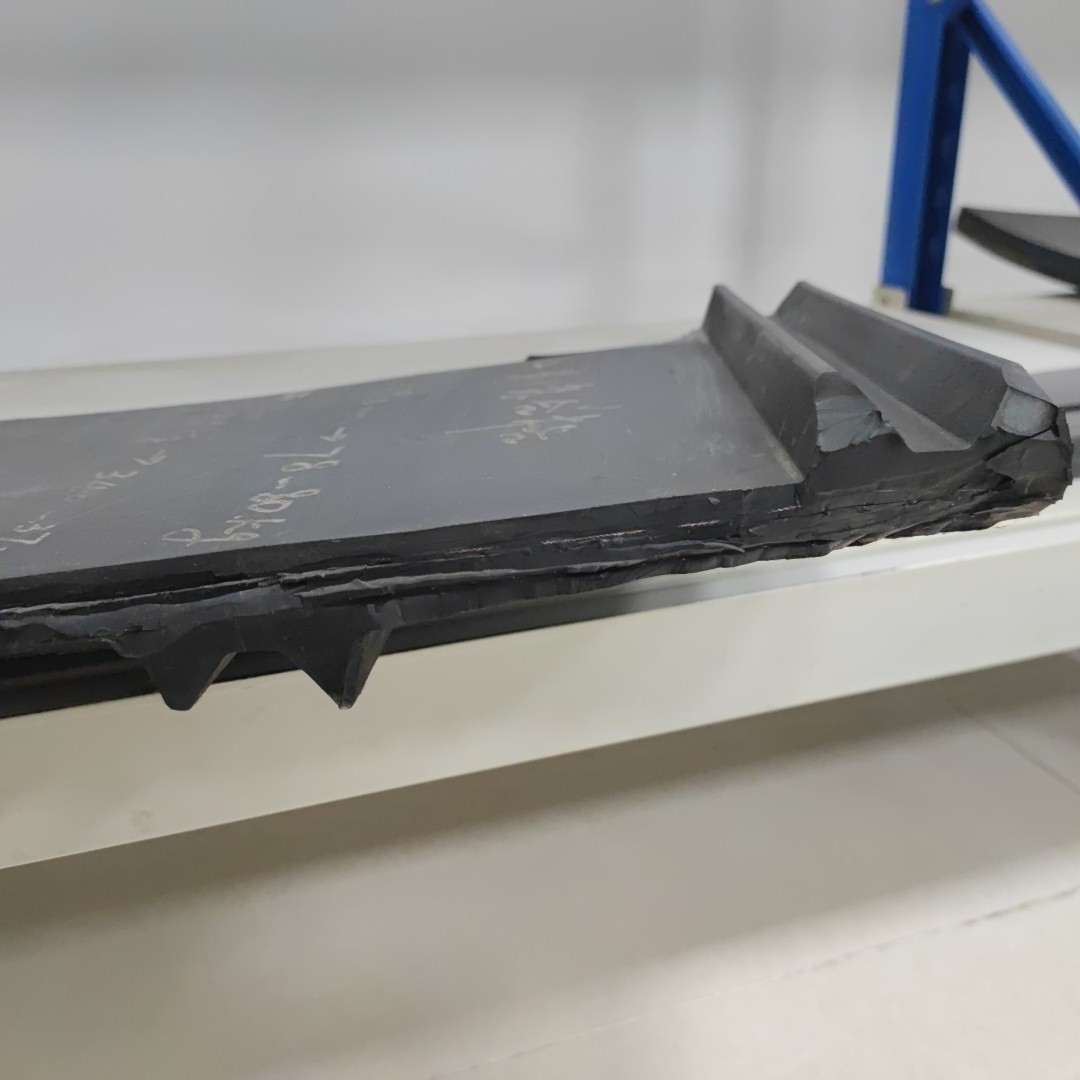

Product model

|

CCJ-13

|

|

Product name

|

Cable belt

|

|

Skeleton material

|

ST/EP

|

|

Colour

|

Black

|

|

Size

|

Custom

|

|

|

High Wear Resistance

|

|

|

High breaking load

|

|

|

Low elongation at working load

|

|

|

Aging proof

|

|

|

60°±5°(cable traction)

|

|

|

50°±5°(option cable ;plastic and pipe traction etc.) )

|

|

|

80°±5°(custom)

|

|

Max. temperature

|

+100℃

|

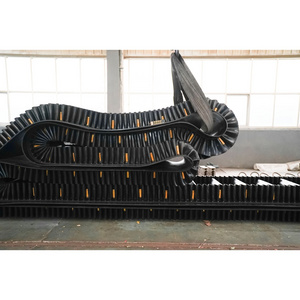

Features:

1.Simple and robust

2.Conveying lengths from 1 km (0.62 miles) to 30 km (18.64 miles)

3.Able to negotiate horizontal curves down to 500 meters radii

4.Conveying capacity from 500 mtph to 4000 mtph

5.Speeds from 3.0 meters per second to 7.5 meters per second

6.Wide range of material with varying properties including density and lump size (e.g.coal, bauxite, potash, limestone ,copper ore ,nickel ore and iron ore)

.No intermediate transfer points.

2.Conveying lengths from 1 km (0.62 miles) to 30 km (18.64 miles)

3.Able to negotiate horizontal curves down to 500 meters radii

4.Conveying capacity from 500 mtph to 4000 mtph

5.Speeds from 3.0 meters per second to 7.5 meters per second

6.Wide range of material with varying properties including density and lump size (e.g.coal, bauxite, potash, limestone ,copper ore ,nickel ore and iron ore)

.No intermediate transfer points.

Applications:

Cable belt conveyors are ideal for:

1.Long distance conveying

2.Where trucking material is costly

3.Site conditions with:

1)Difficult and rugged terrain

2)Temperature extremes

3)Extreme elevation changes ,steep inclines of steep declines(18 degrees max)

4)Corridor restrictions (properly acquisition ,right of way ,water crossings ,road crossings, power line crossings ,animal

crossings)

1.Long distance conveying

2.Where trucking material is costly

3.Site conditions with:

1)Difficult and rugged terrain

2)Temperature extremes

3)Extreme elevation changes ,steep inclines of steep declines(18 degrees max)

4)Corridor restrictions (properly acquisition ,right of way ,water crossings ,road crossings, power line crossings ,animal

crossings)

Applicable industries

1.Mining

2.Aggregates

3.Bulk ports and terminals

1.Mining

2.Aggregates

3.Bulk ports and terminals

CMH offers rubber conveyor belts with different characteristics

Heat Resistant Conveyor Belt

Cold Resistant Conveyor Belt

Oil Resistant Conveyor Belt

Cable Belt

Low Rolling Resistance(LRR) Conveyor Belt

Pipe Conveyor Belt

Production Process and Quality Control

Step 1:

Raw material inspection

Rubber Compound test

ST Steel Cord Test

Step 2:

Advance equipment to guarantee quality from the details

Mixing

process

Rubber is a mixture of a variety of ingredients, but the strong viscosity of rubber leads to various ingredients are difficult to directly mix evenly, need to be added to the mixer repeatedly stirred, mixed evenly.

Calendering process

The heated mixed rubber is produced into the desired rubber sheet semi-finished product by rotating and horizontally setting the gap between two rollers in a relative and horizontal manner.

Forming process

The rubber sheet semi-finished product obtained by calendering is made into the required semi-finished product by the forming mechanism according to different specifications.

Step 3:

Vulcanization Process

Step 4: Finished Product and

Technical data test

Finished belt

Relative inspection in production

Test the appearance, size, mechanical properties and other aspects of the conveyor belt produced to ensure that it meets the standard requirements.

Application

Ports

Cement

Quarry

Steelworks

Copper mine

Power Plant

Packing & Delivery

Hot Searches