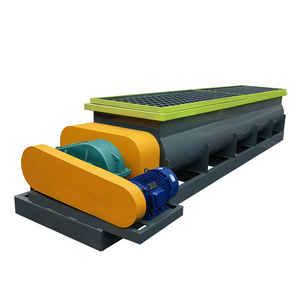

This mixer is suitable for mixing various raw materials such as compound feed, concentrated feed, additive premix, organic and compound fertilizer. The working principle is that the material enters the mixing tank, and is uniformly stirred through the spiral blades installed on a pair of oppositely rotating double shafts.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

China

-

Brand Name:

-

Gate

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

3700*800*750mm

-

Power (kW):

-

12 kW

-

Name:

-

Fast Delivery Micro Mixed npk Fertilizer Machine

-

Keyword:

-

bb fertilizer mixer

-

Function:

-

bb fertilizer mixer

-

Capacity:

-

Customers' Request

-

Mixing type:

-

Scraper Mixer Paddle

-

Mixing speed:

-

35 R/min

-

warranty:

-

5 years

-

Used for goods:

-

Fertilizer Raw Materials

-

Related machine:

-

Fertilizer granulator

Quick Details

-

Barrel Volume (L):

-

1200 L

-

Max. Loading Volume (L):

-

500 L

-

Max. Loading Capacity:

-

1200kg

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

China

-

Brand Name:

-

Gate

-

Voltage:

-

220/380V

-

Dimension(L*W*H):

-

3700*800*750mm

-

Power (kW):

-

12 kW

-

Name:

-

Fast Delivery Micro Mixed npk Fertilizer Machine

-

Keyword:

-

bb fertilizer mixer

-

Function:

-

bb fertilizer mixer

-

Capacity:

-

Customers' Request

-

Mixing type:

-

Scraper Mixer Paddle

-

Mixing speed:

-

35 R/min

-

warranty:

-

5 years

-

Used for goods:

-

Fertilizer Raw Materials

-

Related machine:

-

Fertilizer granulator

Range Of Application

Product Details

|

Product Name

|

Output

|

Size

|

Powder

|

Speed

|

|

GTM-8030D

|

2-8 T/H

|

4950*1650*800

|

18.5KW

|

1450r/min

|

|

GTM-8040D

|

3-10T/H

|

5950*1650*800

|

18.5KW

|

1450r/min

|

|

GTM-1050D

|

6-22t/h

|

226000*1900*1000

|

22KW

|

1450r/min

|

The double-shaft mixer is mainly composed of housing, spiral shaft assembly, driving device, piping, cover plate, chain cover and other components. The shell is mainly welded by plate and section steel and assembled with other components, which is the support of the double-shaft mixer. The shell seal is tight, there will be no flying ash, ash leakage phenomenon.

Working principle

Double shaft mixer using two symmetrical spiral shaft synchronous rotation, in conveying dry ash and other powdery materials at the same time add water stirring, uniform humidifying dry ash powdery materials, so that the humidifying material does not dry ash and does not ooze water droplets, so as to facilitate the humidifying ash loading transport or transfer to other conveying equipment

Cost saving

Double-shaft stirring is faster and more uniform than single-shaft stirring.

The reduction gears are matched to ensure stable mixing.

Low energy consumption, high uniformity of mixed fertilizer, and less material residue.

The mixing speed is uniform, and the noise during the mixing process is low.

The main body of high-quality carbon steel is durable and easy to maintain.

Our Service

Pre-sale

Our account manager will communicate with you the product requirements related to your machine

We offer free product plans, packaging drawings and 3D renderings to save your budget

We will provide our own quotation and proof of our machines

We have a professional R & D department, to provide you with the most professional technical support

We can make granulation experiment according to your raw materials

On sale

1、During the production of the equipment, we will feed back the production progress to you

2、We support customer on-site inspection,video inspection, third party inspection, factory inspection agency inspection

3、

We can provide certificate of origin, customs clearance and other certificates

4、We offer you a free test service before the machine leaves the factory

5、

We also provide equipment packing diagram

After sale

1、If you need to install, we have a professional overseas installation team ,

We will provide you with installation drawings or a video guide for making the installation

2、We support to provide you with free accessories within one year of purchase of machine equipment

3、We will provide a five year warranty on important parts of the equipment

Transaction Customer

Customer evaluation & Production site

This is part of our customer site and customer praise display, if you want to communicate with these customers, please contact us

Hot Searches