- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hezhi

-

Use:

-

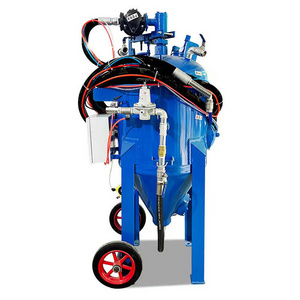

Shot blasting / Sand Blasting

-

Size:

-

Min 0.2mm

-

Appearance:

-

spherical / round

-

Usage:

-

shot peening; sand blasting, polishing; derusting; cleaning

-

Packing:

-

25kg/bag

Quick Details

-

Type:

-

blasting media, abrasive

-

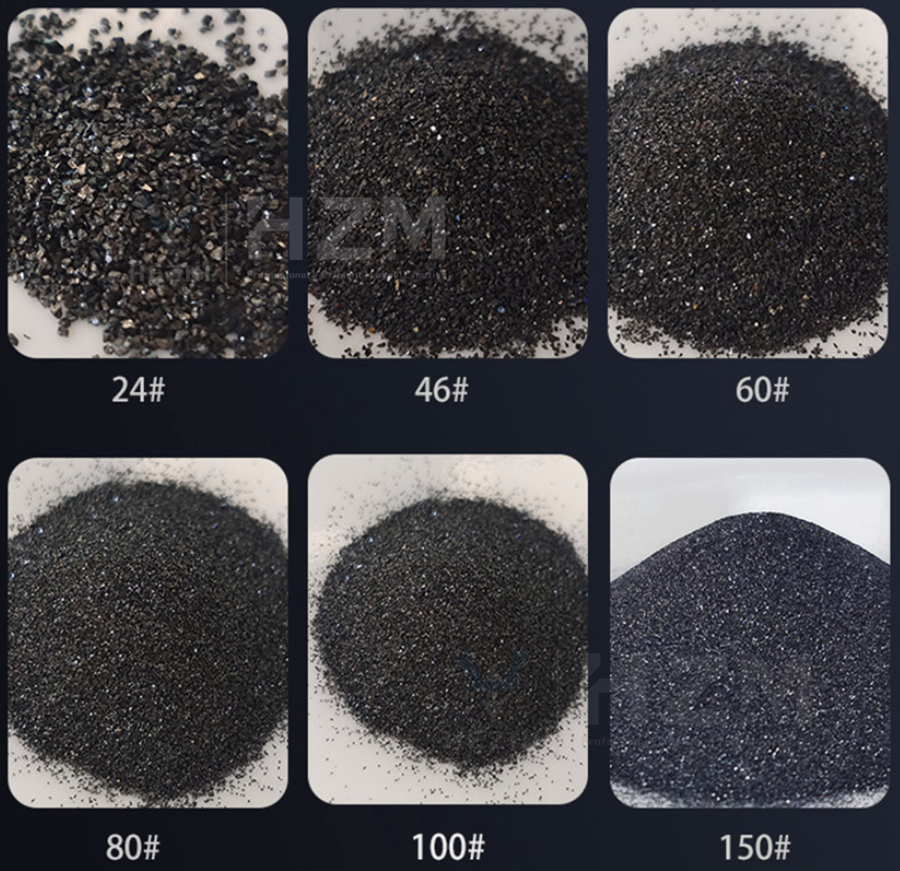

Abrasive Grain Sizes:

-

Min 0.2mm

-

Warranty:

-

1 year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hezhi

-

Use:

-

Shot blasting / Sand Blasting

-

Size:

-

Min 0.2mm

-

Appearance:

-

spherical / round

-

Usage:

-

shot peening; sand blasting, polishing; derusting; cleaning

-

Packing:

-

25kg/bag

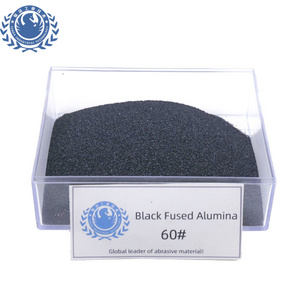

Black corundum is also known as low-aluminum corundum. The main raw material is aluminum oxide (AI2O3) with a content of 70% to 80%. It contains more impurities such as silicon oxide and titanium oxide. It is a gray-black crystal and is characterized by a low content of Al2O3. , And a certain amount of Fe2O3 (about 10%), moderate hardness, high toughness, high temperature resistance, and stable thermal performance. Widely used in sandblasting cleaning of sandblasting machines.

Melting point (°C) 2050

The maximum temperature (°C) 1850

True Density (g/cm3) ≥ 3. 50

Linear expansion coefficient (0-1600 °C) 7-9

High content industry calcined black fused alumina Application

Products cover Moulding Equipment,Sand Reclamation Equipment, Sand Mixer, Dust Collector and full-line Shot Blasting Machines.

We owned 3600m2 work shop area for production with 2x10 cranes.

Another 2600m2 space is planned for extension.

ISO9001 is achieved. Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3D Solidworks is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer, our staff and our company.

Choose Hezhi,Get factory price and reliable Machinery!

Q

: How many days do you need to produce this machine?

A

: It depends on the size of the machine. Usually

20days -30days for shot blasting machine and sand machine,45days for production line equipment.

Q:

How to control your quality ?

A:

First of all, we have professional technical team to design the machine. And we have strict production system, the quality inspection department will check the quality regularly.

For the smaller machine we will install the machine at our workshop to make sure it can work well.

For the bigger machine, we will install the machine for our customers until it can work well

Q:

What's your machine quality guarantee?

A:

Usually it's one year. We will choose the world famous brand components to keep our machine in perfect working condition.

Q:

Can you instal the machine overseas?How long will it take?

A:

YES, we have rich-experienced install team to instal the machine for our customers worldwide.