- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or Customizable

-

Power:

-

35KW to 400KW (customized)

-

Dimension(L*W*H):

-

L4500mm*W5000mm*H3000mm or customizable

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Coating application/coating substrate:

-

metal , glass and plastic products

-

Raw coating material:

-

Titanium , chrome, Aluminum, Brass, Zirconium,etc.

-

Coating application field:

-

Stainless steel products, glass, ceramic, chrome plated products

-

Coating color:

-

Golden, rose golden, black, dark black,champagne, Brown,etc.

-

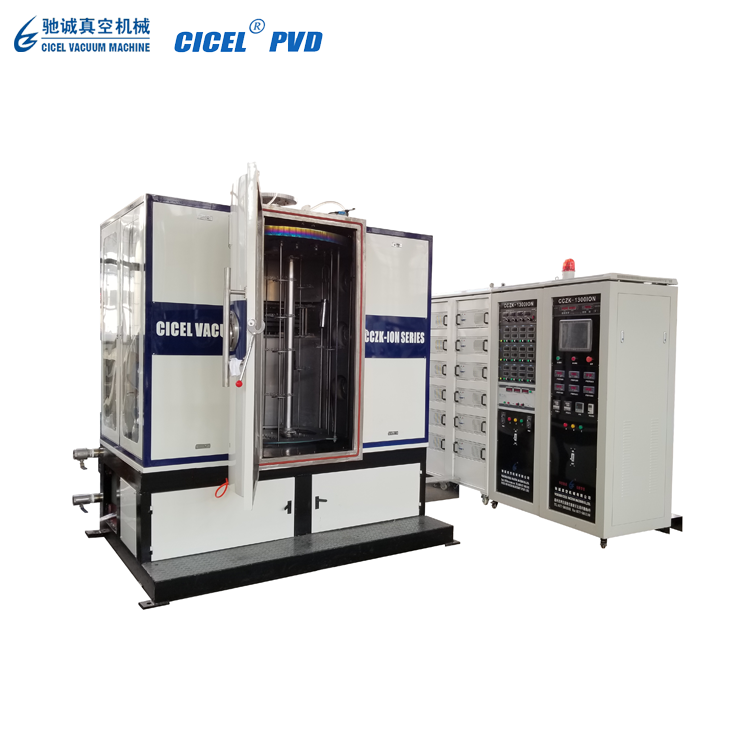

Coating technology:

-

Multi-arc Ion PVD coating technology

-

Installation and training:

-

Free oversea installing and training service

-

Control mode:

-

PLC+Touch screen+Alarm system , Full Automatic

-

vacuum system:

-

Diffussion pump/ molecular pump+roots pump+rotary vacuum pump

-

Ultimate vacuum:

-

5*10-4pa

-

Weight:

-

3ton to 25tons

-

Certification:

-

ISO9001:2015 & CE&TUV

Quick Details

-

Machine Type:

-

vacuum coating

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

CICEL

-

Voltage:

-

380V or Customizable

-

Power:

-

35KW to 400KW (customized)

-

Dimension(L*W*H):

-

L4500mm*W5000mm*H3000mm or customizable

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Coating application/coating substrate:

-

metal , glass and plastic products

-

Raw coating material:

-

Titanium , chrome, Aluminum, Brass, Zirconium,etc.

-

Coating application field:

-

Stainless steel products, glass, ceramic, chrome plated products

-

Coating color:

-

Golden, rose golden, black, dark black,champagne, Brown,etc.

-

Coating technology:

-

Multi-arc Ion PVD coating technology

-

Installation and training:

-

Free oversea installing and training service

-

Control mode:

-

PLC+Touch screen+Alarm system , Full Automatic

-

vacuum system:

-

Diffussion pump/ molecular pump+roots pump+rotary vacuum pump

-

Ultimate vacuum:

-

5*10-4pa

-

Weight:

-

3ton to 25tons

-

Certification:

-

ISO9001:2015 & CE&TUV

You are here: Home >> CCZK-ION series PVD multi arc vacuum coater

Vaccum Magnetron Sputtering Glass Mirror Coating Line/device for PVD system/vacuum chroming finishing machines

|

configuration Model |

CCZK-700-ION |

CCZK-1000-ION |

CCZK-1300-ION |

CCZK-1600-ION |

CCZK-1800-ION |

CCZK-2000-ION |

CCZK-2200-ION |

|

Chamber size(MM) |

D700*H700 |

D1000*H1200 |

D1300*H1500 |

D1600*H1800 |

D1800*H2000 |

D2000*H2400 |

D2200*H4000 |

|

Vacuum system |

Diffusion pump/Molecular pump + Roots pump + Double stage direct driver Rotary pump + Holding pump + Cryogenic pump(optional) |

||||||

|

Arc power supply |

7th generation 4sets |

7th generation 8sets |

7th generation 12sets |

7th generation 16sets |

7th generation 20sets |

7th generation 24sets |

7th generation 40sets |

|

Arc source |

7th generation 4sets |

7th generation 8sets |

7th generation 12sets |

7th generation 16sets |

7th generation 20sets |

7th generation 24sets |

7th generation 40sets |

|

Bias power supply |

12KW |

20KW |

30KW |

40KW |

60KW |

60KW |

80KW |

|

Gas MFC system |

4-way intake sys |

4-way intake sys |

4-way intake sys |

4-way intake sys |

4-way intake sys |

4-way intake sys |

4-way intake sys |

|

Baking system |

Up to 350C |

Up to 350C |

Up to 350C |

Up to 350C |

Up to 350C |

Up to 350C |

Up to 350C |

|

Control system |

IPC + PLC+HMI Full automatic + Remote control system ( optional) |

||||||

|

Ultimate vacuum |

5.0*10-4pa |

5.0*10-4pa |

5.0*10-4pa |

5.0*10-4pa |

5.0*10-4pa |

5.0*10-4pa |

5.0*10-4pa |

|

Total power |

50KW |

75KW |

145KW |

190KW |

250KW |

305KW |

455KW |

|

Coating Cycle time |

Around 15 to 50 mins one cycle ( Depending on the coating film layer of different coating products) |

||||||

|

Delivery container size |

1set 20GP |

1set 20GP |

1set 20GP |

1set 40HQ |

1set 40HQ |

1set 20FR 1set 40GP |

1set 20FR 2sets 40HQ |

|

Machine installing time |

7days (1engineer) |

7days (1engineer) |

7days (1engineer) |

10days (2engineers) |

10days (2engineers) |

15days (2engineers) |

20days (2engineers) |

|

Customized Size is available |

Customized |

||||||