- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Boqiao, Boqiao

-

Model Number:

-

YH9151AB, YH9151AB

-

Type:

-

Two Component, Two Component

-

Product name:

-

Potting Glue For Electronic

-

Keywords:

-

electronic potting glue

-

Viscosity:

-

40000-45000

-

Advantage:

-

Suitable High Temperate Climates

-

MOQ:

-

1 KG

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

Quick Details

-

CAS No.:

-

67763-03-05

-

Other Names:

-

epoxy resin and hardener

-

MF:

-

mSiO2 nH2O

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Boqiao, Boqiao

-

Model Number:

-

YH9151AB, YH9151AB

-

Type:

-

Two Component, Two Component

-

Product name:

-

Potting Glue For Electronic

-

Keywords:

-

electronic potting glue

-

Viscosity:

-

40000-45000

-

Advantage:

-

Suitable High Temperate Climates

-

MOQ:

-

1 KG

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

BEFORE YOU BUY

NOTE!!!!!!

Before you place order, please contact me to confirm shipping cost!

Product Description

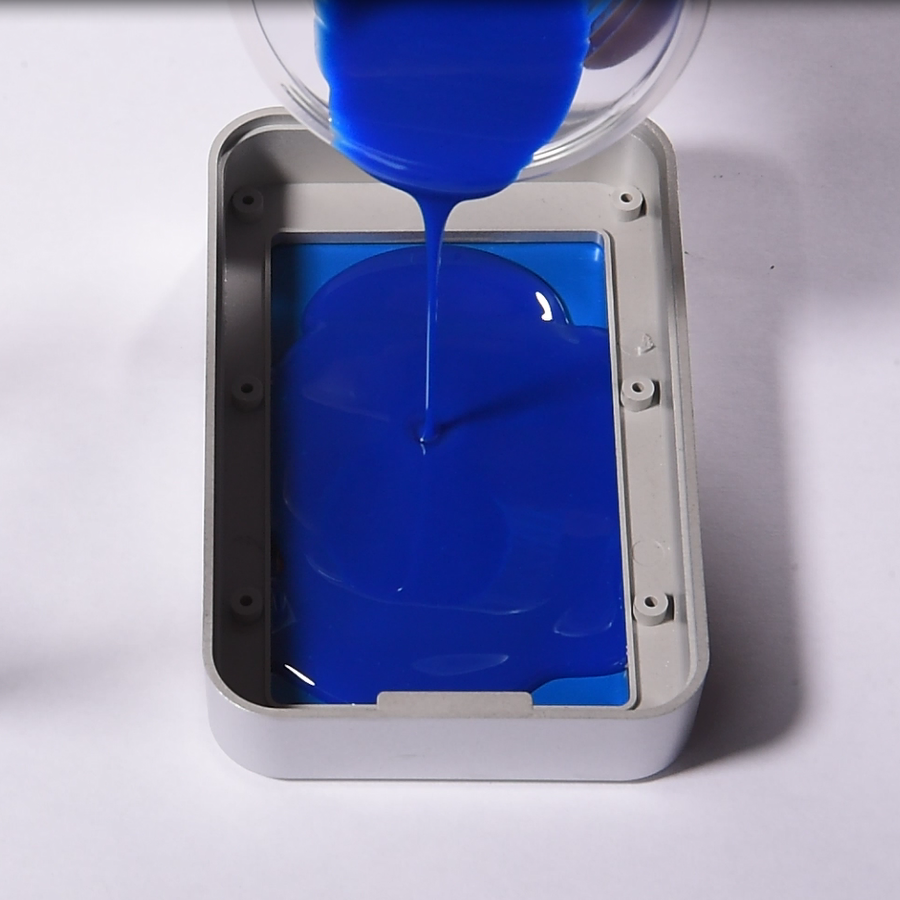

Electrical Epoxy Resin

High Thermal Conductivity

YH-9151A/B is a two-component epoxy system, white, potting glue, low viscosity, good fluidity, good leveling, with the following characteristics: 1. This product is a white epoxy potting compound with low viscosity, good fluidity and easy penetration into the gap of the product; 2. It can be cured at room temperature or medium temperature, or heated, and the curing speed is moderate; 3. No bubbles, smooth surface, high heat resistance, good gloss and high hardness after curing;

Scope of use

1. It can be used for any electronic or other products that need perfusion sealing, encapsulation protection, insulation and moisture-proof; 2. Widely used in the potting of transformers, sensors, buzzers, atomizers, negative ion generators, aquarium pumps, ignition coils, power modules, electronic controllers and other electronic components; 3. Especially recommended for priming of motor coils.

Technical indicators

|

Test items

|

unit

|

YH-9151A

|

YH-9151B

|

|

Exterior

|

--

|

white liquid

|

Transparent liquid

|

|

Density

|

25℃,g/cm3

|

1.70~1.80

|

1.13~1.16

|

|

Viscosity

|

25℃,mPa.s

|

9000~13000

|

100~300

|

It is recommended to wear protective equipment such as gloves, masks and goggles during use. In order to achieve the best performance of the product, it should be accurately weighed during use.

Instructions

|

Test Conditions

|

Test Conditions

|

Measurements

|

|

Mixing ratio (A:B)

|

weight ratio

|

5:1

|

|

mixed viscosity

|

25℃

|

2000-3000mPa.s

|

|

Available time

|

25℃ (mixing amount 800g)

|

20-30 minutes

|

1. Weighing: In order to achieve the best performance of the product, it is recommended to use a high-precision electronic scale for accurate weighing. 2. Mixing: Mix the weighed materials A and B and stir them evenly; during manual stirring, ensure that the resin on the wall and bottom of the container is fully dispersed. 3. Pouring: Pour the mixed materials A and B into the object to be poured, and cure at room temperature or medium temperature. 4. Recommended curing process: normal temperature/12-16 hours, heating at 50-60℃, 3-4 hours, heating, +100℃/2h. 5. The more the amount of glue mixed together, the faster the reaction will be, the faster the curing speed will be, and it may be accompanied by a lot of heat. Please pay attention to controlling the amount of glue at one time The time will also be shortened, and the mixed glue should be used up in a short time as much as possible; 6. Before using in large quantities, please try a small amount first to master the use skills of the product to avoid mistakes; 7. After pouring, the glue will gradually penetrate into the gap of the product. If necessary, please carry out the second pouring;

8. During the curing process, please keep the environment clean to prevent impurities or dust from falling onto the surface of the uncured glue.

Parameters after curing

|

project

|

unit or condition

|

Measurements

|

|

Hardness

|

SHORE-D

|

80±3

|

|

Volume resistivity

|

25℃,Ω.cm >1.35×1015

|

>1.35×1015

|

|

Surface resistivity

|

25℃, Ω

|

>1.2×1014

|

|

Dielectric strength

|

25℃, Kv/mm

|

>25

|

|

Dielectric Constant (50Hz)

|

--

|

4.80-5.30

|

|

Dielectric loss

|

Tδ

|

0.03-0.05

|

|

Tensile strength

|

MPa

|

25-30

|

|

Bending strength

|

MPa

|

72-85

|

|

Impact strength

|

KJ/m

2

|

30--35

|

|

Glass transition temperature Tg

|

°C

|

78

|

|

Temperature resistance

|

°C

|

-45-+135

|

Note: The above performance data is based on 24 hours of complete curing test at room temperature, and is only for reference when customers use it. It cannot fully guarantee that all the above values can be achieved in a specific environment. Please use the measured data as the standard.

Emergency measures

Eye contamination from resin, hardener or mixture should be flushed immediately with clean tap water for 10 to 15 minutes. A doctor should then be consulted. Material smeared or splashed on the skin should be wiped off and the contaminated area washed and treated with a cleansing cream. In the event of severe irritation or burns, a physician should be consulted. Contaminated clothing should be changed immediately.

storage & packing

|

Part A

|

Part B

|

Other (can be customized)

|

|

5KG/25kg Bucket

|

5KG/bucket

|

1kg/2kg/5kg/20kg

|

The product should be stored and sealed in a cool and ventilated environment at 25 ° C; the hardener is relatively sensitive to moisture in the air and should be sealed in time when not used up.

Company profile

Hot Searches