- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

no

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LTD

-

Model Number:

-

LC1001

-

Type:

-

Gel/Paste

-

product name:

-

rtv electrical sealant

-

Feature:

-

anti-seismic,anti-corona,anti-leakage and aging

-

Relative Density (g/cm3):

-

1.6~1.65

-

Adhesion (cps):

-

80000~90000

-

Hardness(Shore A):

-

35~45

-

Conductivity (W/mk):

-

≥1.2

-

Voltage Resistivity:

-

3*1015

-

Certificate:

-

ROHS REACH

-

flame retardant grade:

-

V0

-

temperature resistance:

-

60 ~ 280

Quick Details

-

CAS No.:

-

no

-

Other Names:

-

RTV silicone adhesive

-

MF:

-

no

-

EINECS No.:

-

no

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LTD

-

Model Number:

-

LC1001

-

Type:

-

Gel/Paste

-

product name:

-

rtv electrical sealant

-

Feature:

-

anti-seismic,anti-corona,anti-leakage and aging

-

Relative Density (g/cm3):

-

1.6~1.65

-

Adhesion (cps):

-

80000~90000

-

Hardness(Shore A):

-

35~45

-

Conductivity (W/mk):

-

≥1.2

-

Voltage Resistivity:

-

3*1015

-

Certificate:

-

ROHS REACH

-

flame retardant grade:

-

V0

-

temperature resistance:

-

60 ~ 280

High Power Led Lamps Semi-Flowing Heat-Resistant Silicone Adhesive Sealant Silicone Glue Electrically Rtv Electrical Sealant

| Product Name | High Power Led Lamps Semi-Flowing Heat-Resistant Silicone Adhesive Sealant Silicone Glue Electrically Rtv Electrical Sealant |

| Model | LC1001 |

| Conductivity (W/m) | ≥1.2 |

| Features | Good adhesion/High thermal conductivity/Single part |

| Hardness(Shore A) | 35~45 |

| Sample | Freely Offered |

| Usage | Heat transfer/fixing/V0/sealant |

| Appearance | White,Semiliquid |

| Application | LED/Electrical power/Microwave oven/Electronic components... |

| Adhesion (cps) | 80000~90000 |

| Curing Time | 3~7d |

| MOQ | 50 Pcs |

| Lead time | Within 1-3 working days |

| Payment | Paypal/WU/TT/Trade Assurance/Money Gram/Cash |

| Shipping |

DHL/UPS/FedEx/Aramex/EMS/HK Post |

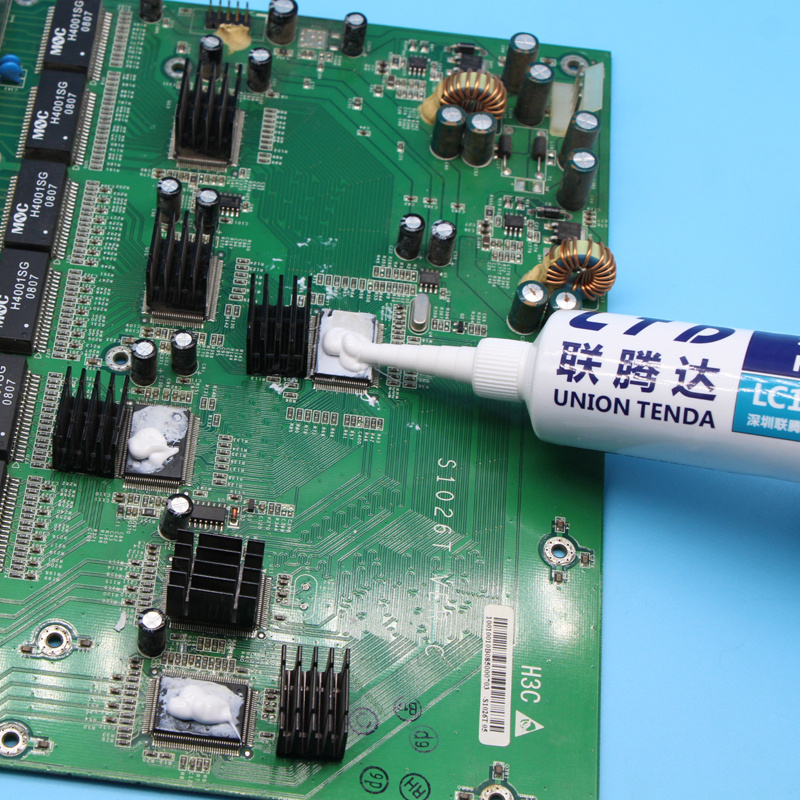

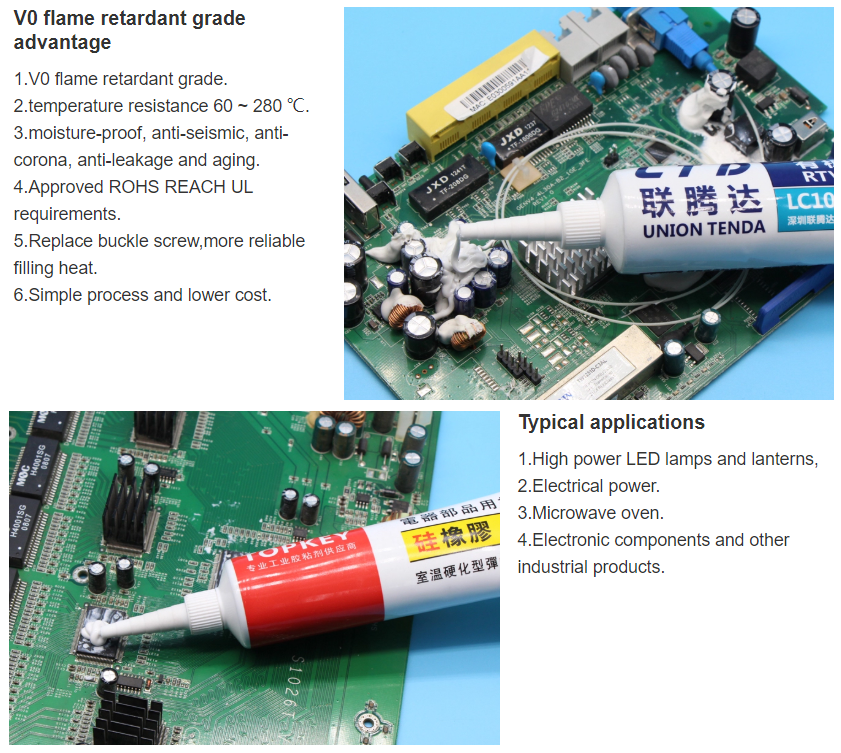

LC1001 Thermal Conductive Silicone Glue

LC1001 is the semi-flowing heat-resistant silicone adhesive sealant which is made of special silicone rubber material the addition of thermal powders. With excellent conductivity,V0 flame retardant grade, excellent temperature resistance, can be in the range of 60 ~ 280 ℃ Long-term use. As well as good adhesion, long term use will not fall off, will not produce Contact gap to reduce thermal conductivity, moisture-proof, anti-seismic, anti-leakage and aging .The properties are widely used for the adhesion and sealing of the electronic components with high thermal conductivity, which is a single part of the ac etone oxime type, It can be cured silicone rubber and conforms to the requirements of ROHS REACH UL.

Typical Applications

High power LED lamps and lanterns, electrical power, microwave oven, electronic components and other industrial products of thermal conductive adhesive sealing, alternative thermal conductive silicone used in high-power electric module and radiator thermal conductivity between fixed filling adhesive, no card buckle screw, more reliable filling heat, simple process and lower cost.

Applying Process

1. Surface clean : Clean the surface of the adhesive object and remove the rust, dust and oil.

2. Sizing: Twist the cap of the hose, squeeze the gel into the clean surface, and make it natural.

3. Curing: Place the bonded or sealed parts in the air while them to solidify naturally. Curing is a process from surface to the internal, within 24 hours (at room temperature and 55% relative humidity) will cure the depth of the 2 ~ 4 mm, if the site location is deeper that completely curing time will be postpone, especially it is not easy to come into contact with air. if the temperature is low, cure time also will be postpone .Prior to further processing or wrapping the bonded parts, it is recommended that the user wait long enough to ensure that the adhesion and integrity of the adhesion are not affected.

Note : After the operation is completed, the unused glue should be tightened immediately and sealed. When used again, if the seal has a little bit of skin, remove it. In the process of storage, a small amount of curing phenomenon may occur in the pipe mouth, which can be used normally unaffected the product performance.

Physical Properties:

|

Performance Evaluation |

LC1001 |

|

|

Uncured |

Appearance |

White, Semiliquid |

|

Relative Density (g/cm3) |

1.6~1.65 |

|

|

Adhesion (cps) |

80000~90000 |

|

|

TFT min (min℃) |

≤10 |

|

|

Curing Time(d) |

3~7 |

|

|

Curing Type |

One component deethanol type |

|

|

Cured |

Tensile Strength(MPa) |

≥1.5 |

|

Elongation at Break (%) |

200~400 |

|

|

Hardness(Shore A) |

35~45 |

|

|

Shear Strength(MPa |

≥1.0 |

|

|

Peel Strength(N/mm |

≥5 |

|

|

Linear Shrinkage(%) |

≤0.5 |

|

|

Conductivity (W/m·k) |

≥1.2 |

|

|

Voltage Resistivity (Ω·cm) |

3×1015 |

|

|

Dielectric strength (kV/m· m) |

20 |

|

|

Permittivity (1.2MHz) |

2.8 |

|

Packing Specification: 100ML/ 100PCS/Carton,300ML/ 25PCS/Carton,2.6L/4PCS/Carton

Q1: What's the thermal conductivity test method given on the data sheet ?

Q5: How to ship the orders ?

kindly tell us before shipping out. Q6: What's the leading time ? A6: Sample order costs 1~3 workdays and 3~7 workdays for mass production.