- Product Details

- {{item.text}}

Quick Details

-

Effective Volume:

-

4/6/8/10 m3

-

Dimension(L*W*H):

-

12m*1.8m*1.5m

-

Voltage:

-

220v/380v

-

Power:

-

11

-

Applicable Industries:

-

Other

-

Weight (KG):

-

12000

-

Keywords:

-

activated carbon furnaces

-

Raw material:

-

Coconut Shell

-

Usage:

-

Activated Carbon

-

Applicable raw materials:

-

Waste Wood

-

Advantage:

-

Continuous Working Environment Friendly

-

Application:

-

Making Charocal

-

Capacity:

-

0.8-1T/H

-

Feature:

-

High Carbonizing Efficiency

-

Final product:

-

Activited carbon

-

After-sales Service Provided:

-

Online Service

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2024

-

Brand Name:

-

HJ

-

Effective Volume:

-

4/6/8/10 m3

-

Dimension(L*W*H):

-

12m*1.8m*1.5m

-

Voltage:

-

220v/380v

-

Power:

-

11

-

Applicable Industries:

-

Other

-

Weight (KG):

-

12000

-

Keywords:

-

activated carbon furnaces

-

Raw material:

-

Coconut Shell

-

Usage:

-

Activated Carbon

-

Applicable raw materials:

-

Waste Wood

-

Advantage:

-

Continuous Working Environment Friendly

-

Application:

-

Making Charocal

-

Capacity:

-

0.8-1T/H

-

Feature:

-

High Carbonizing Efficiency

-

Final product:

-

Activited carbon

-

After-sales Service Provided:

-

Online Service

Product Description

Specification

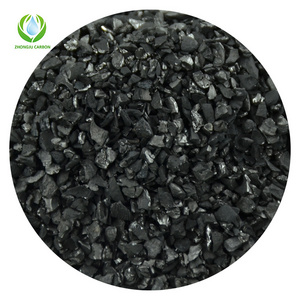

Activated carbon is a functional carbon material made through high-temperature pyrolysis. Due to its large specific surface area, developed pore structure, high adsorption efficiency, and good chemical properties, it is widely used in industry, agriculture, medicine, food and other aspects, such as gas purification , sewage treatment, pharmaceutical industry, sugar production, etc.

|

Model

|

Capacity(kg/h)

|

|

HJ-H5

|

50

|

|

HJ-H8

|

100-150

|

|

HJ-H20

|

250-300

|

|

HJ-H40

|

400-500

|

|

HJ-H50

|

500-600

|

Process technology

1. Crusher : The crusher crushes the raw materials into suitable sizes.

2. Drying (dust removal) : The rotary drum dryer dries the crushed raw materials until the moisture content reaches a suitable range.

3. Continuous carbonization furnace (dust removal) : The raw materials undergo a carbonization process in a continuous carbonization furnace and are finally made into charcoal.

4. Activated carbon stove: After pyrolysis of charcoal at high temperature in an activation furnace, activated carbon is produced.

5. Cooling equipment: The finished activated carbon is cooled and cooled in the cooling equipment.

6. Packaging equipment : The finished activated carbon is bagged and packaged in a unified manner according to different packaging weight requirements.

Features

Ordinary activation furnaces carbon steel furnace tubes will deform at high temperatures of 600 degrees.

The ring ring welded by ordinary carbonization furnace is easy to crack and deform.

Details Images

Common activated carbon

Customer case

Hot Searches