- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

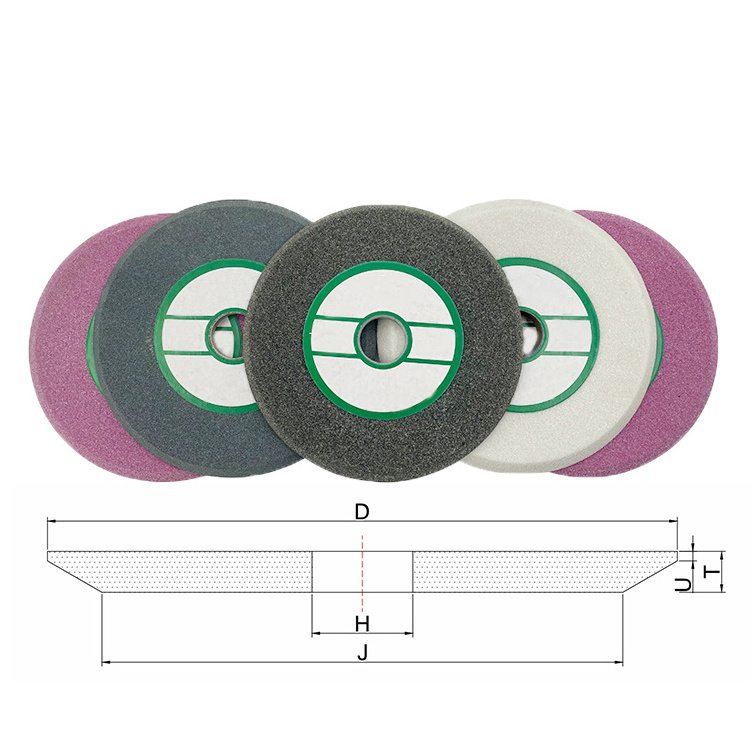

bevel edge grinding wheel

-

Product name:

-

White corundum bevel edge grinding wheel

-

Material:

-

brown corundum, white corundum, green silicon carbide, chrome corundum

-

Bond:

-

Ceramic. Vitrified

-

Grit:

-

#46, #60, #80

-

Hardness:

-

P

-

Speed:

-

35M/S

-

weight:

-

1.1kg

-

Color:

-

Pink Green White Black

-

application:

-

sharpening disc for band blades resharpening machines

-

Product shape:

-

bevel edge corundum wheel (PDX)

Quick Details

-

Type:

-

Abrasive Disc

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Model Number:

-

bevel edge grinding wheel

-

Product name:

-

White corundum bevel edge grinding wheel

-

Material:

-

brown corundum, white corundum, green silicon carbide, chrome corundum

-

Bond:

-

Ceramic. Vitrified

-

Grit:

-

#46, #60, #80

-

Hardness:

-

P

-

Speed:

-

35M/S

-

weight:

-

1.1kg

-

Color:

-

Pink Green White Black

-

application:

-

sharpening disc for band blades resharpening machines

-

Product shape:

-

bevel edge corundum wheel (PDX)

Products Description

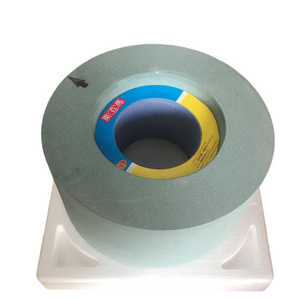

Band saw corundum grinding wheel

*Made of corundum, it has high hardness, good toughness and beautiful appearance.

*It is suitable for grinding metal materials with medium strength and high tensile strength

.

*Such as ordinary carbon steel, alloy steel, malleable cast iron, hard bronze, etc.

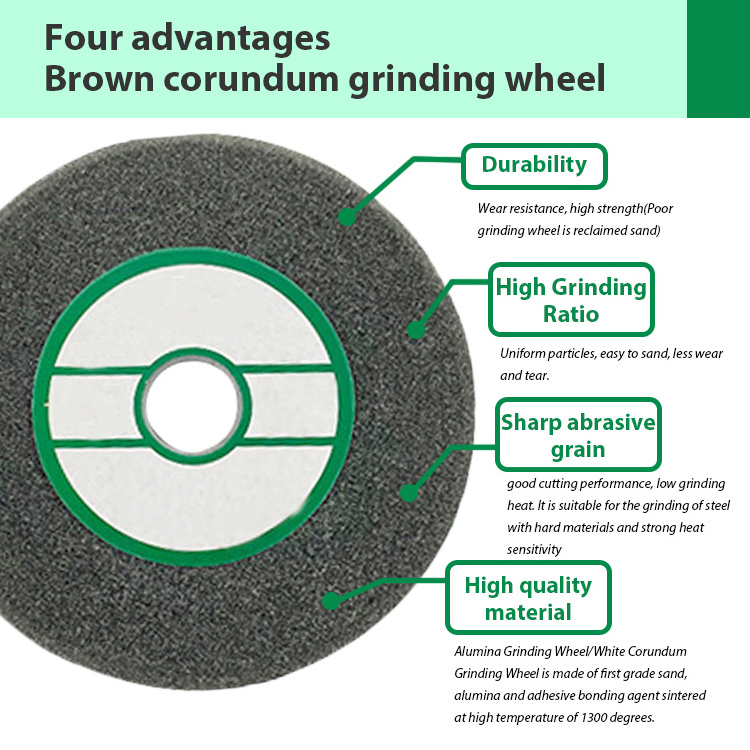

Product Features.

1. It can grind tools quickly and without burrs.

2. For workbench and floor machine. The grinding wheel is balanced and canoperate normally.

3. It has uniform and closely bonded particles, which is suitable for providing a smooth and professional appearance.

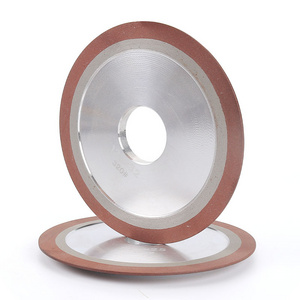

Alumina Grinding Wheel,High hardness, abrasive grains are easily broken, sharp edges and corners, good cutting

performance, low grinding heat, etc. It is suitable for the grinding of steel with hard materials and strong heat sensitivity.

Such as the grinding of hardened steel, high carbon steel, general high speed steel, alloy steel, etc. Mainly used for grinding and forming waste of tools, cutting tools, dies, gears, threads, thin-walled parts, etc

performance, low grinding heat, etc. It is suitable for the grinding of steel with hard materials and strong heat sensitivity.

Such as the grinding of hardened steel, high carbon steel, general high speed steel, alloy steel, etc. Mainly used for grinding and forming waste of tools, cutting tools, dies, gears, threads, thin-walled parts, etc

Small knowledge of material usage:

1. Brown fused alumina (A): suitable for carbon steel, alloy steel, malleable cast iron, hard bronze, etc.

2. White corundum (WA): Suitable for grinding thread grinding materials such as hardened steel, alloy steel, high-speed steel, high-carbon steel, etc.

3. Chrome corundum (PA): suitable for internal grinding of cutting tools, measuring tools, instrument threads, tool steel, stainless steel, quenched workpieces, tool grinding, etc.

4. Green silicon carbide (GC): suitable for hard and brittle materials such as cemented carbide, optical glass, ceramics, gems, and agate.

|

Product size:

|

diameter 150mm, 200mm, 250mm customized size

|

|

|

Product material:

|

brown corundum, white corundum, green silicon carbide, chrome corundum, customized materials

|

|

|

Bonding agent:

|

ceramic bond

|

|

|

Product shape:

|

single edge grinding wheel

|

|

|

Size, hardness, granularity and material can be customized according to customer requirements

|

|

|

Diameters of 150mm, 200mm,

250mm

support customized sizes

Application

Safety several work description:

1. Select the grinding wheel with the spindle revolution of the grinder. Please check the grinding wheel before installation.Do not use it if any cracks or damages are found

2.The clearance between the inner hole of the grinding wheel and the spindle should not be too tight, which is generally controlled between 0.05~0.10 mm. When tightening the nut, do not tighten it too tightly

3, The shield used by the grinder should cover at least half of the diameter of the grinding wheel

4. After the grinder is started, it must be idled for at least 2 minutes. During idling, the operator should stand in a safe position, and it is strictly forbidden to stand in front of the grinding wheel or in the tangent direction

5. The rotation direction of the grinder should be correct, so that the grinding debris can only fly downward from the grinding wheel. Grinding is carried out after the grinder rotates smoothly. If the grinder runout is obvious, it should be stopped in time for dressing

6, The initial grinding can not be too hard, in order to avoid uneven grinding wheel force and accidents. Two people are not allowed to sharpen a knife on the same grinding wheel at the same time

7. It is strictly prohibited to use side grinding to avoid grinding wheel crushing. Do not grind copper, lead, wood and other things to prevent the grinding wheel from impingement

8, The sharpening time is long tool, should be timely cooling, to prevent hot hand

9. Regularly trim the surface balance of the grinding wheel. Keep it properly after use, do not knock against it, keep grinding wheel dry

10, always wear personal protective equipment, mask, eye mask, work cap, etc

11. Follow the instructions

Hot Searches