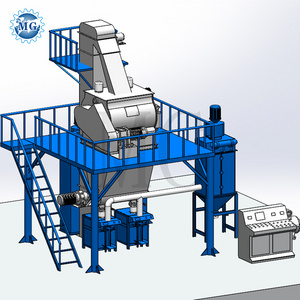

Simple and small dry packaging tile mortar production line is suitable for personal investment, and the output can reach 1-5t/h.

Simple and small dry powder mortar production line (also known as simple dry powder mortar factory, small putty production line)

is on the basis of efficient ribbon powder mixing machine, adding spiral elevator, finished product storage tank, automatic

filling and packaging machine, electric control cabinet and other configurations, to form an effective and reasonable, easy to

operate production line.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V-440V, 50/60Hz

-

Power:

-

15-220kw

-

Dimension(L*W*H):

-

Working Site

-

Weight:

-

2000 kg

-

Features:

-

Convenient Operation

-

Keyword:

-

Dry Powder Mortar Mixing Plant

-

Product name:

-

Simple Dry Powder Mixing Machine

-

Capacity:

-

1-10 T/h

-

Usage:

-

Putty Powder Packing Machine

-

Advantage:

-

Convenient Operation

Quick Details

-

Application:

-

Dry Mortar Production Line

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

tongding

-

Voltage:

-

220V-440V, 50/60Hz

-

Power:

-

15-220kw

-

Dimension(L*W*H):

-

Working Site

-

Weight:

-

2000 kg

-

Features:

-

Convenient Operation

-

Keyword:

-

Dry Powder Mortar Mixing Plant

-

Product name:

-

Simple Dry Powder Mixing Machine

-

Capacity:

-

1-10 T/h

-

Usage:

-

Putty Powder Packing Machine

-

Advantage:

-

Convenient Operation

Equipment Parameter

|

Model

|

Host Motor

|

Capacity(T/H)

|

|

MINI-1000

|

7.5

|

1-3

|

|

MINI-2000

|

11

|

2-6

|

|

MINI-3000

|

15

|

3-9

|

|

MINI-5000

|

22

|

5-10

|

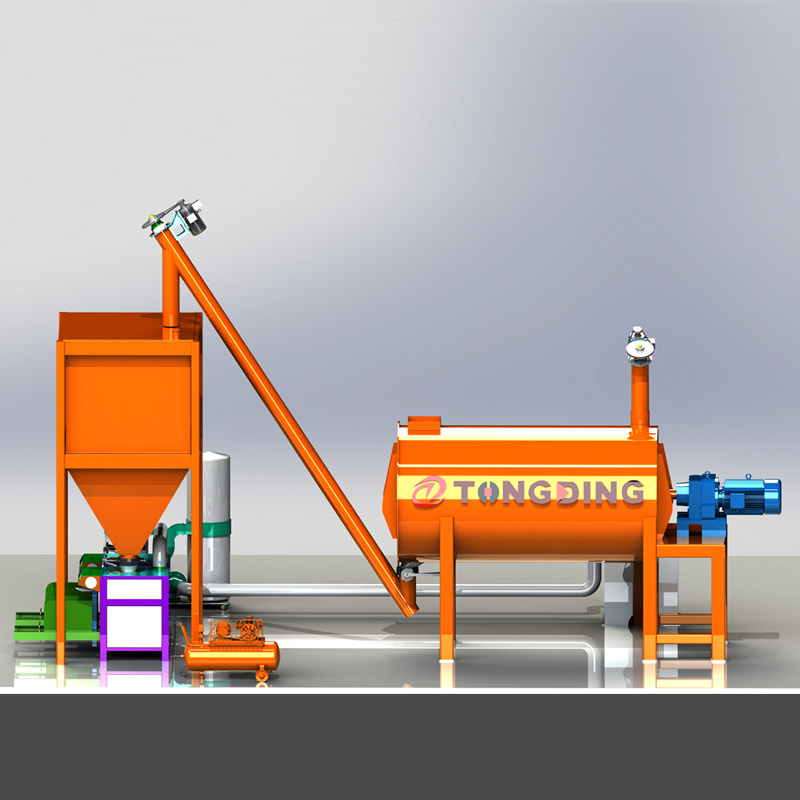

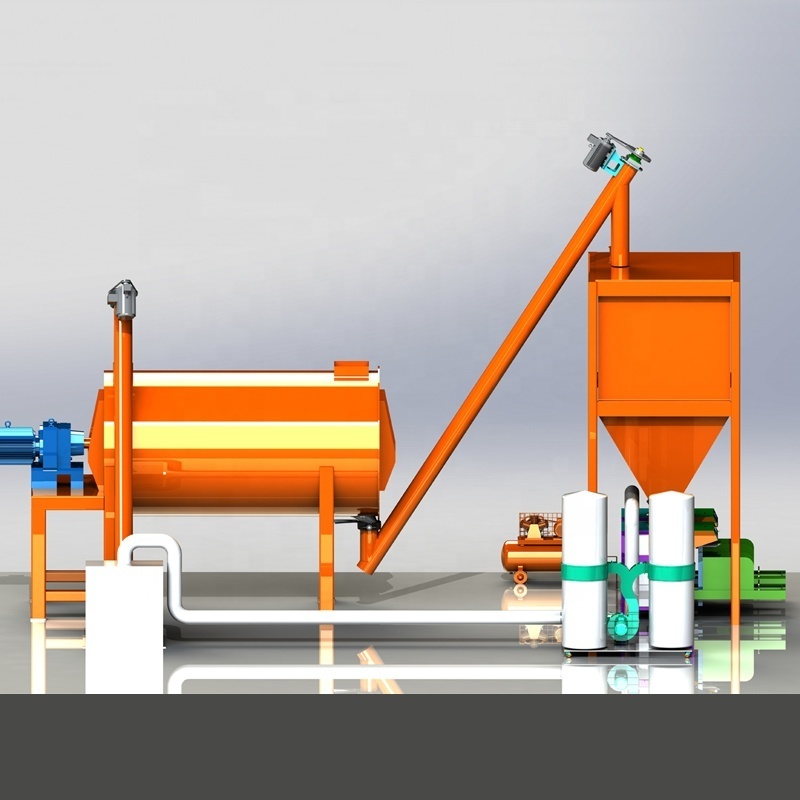

Simple and small dry packaging tile mortar production line is suitable for personal investment, the output can reach 1-10t/h. Simple and small dry powder mortar production line (also known as simple dry powder mortar factory, small putty production line) is on the basis of efficient ribbon powder mixing machine, adding spiral elevator, finished product storage tank, automatic filling and packaging machine, electric control cabinet and other configurations, to form an effective and reasonable, easy to operate production line.

* We support a variety of different models, semi-automatic types, the semi-automatic type output from 1t/h to 10t/h.

* Fully automatic models, daily output of 20 tons, 30 tons, 40 tons, 50 tons, 70 tons, 100 tons, and more than 100 tons.

Detail Presentation

01 Feeding Port

Function:

Feed raw materials and additives though the feeding port into the 1st screw convey.

02 1st Screw Conveyor

Function:

Conveying materials to the mixer.

Feature:

1) The spiral blade adopts wear-resistant steel;

2)

The

patent sealing device to prevent the bearings into the dust.

03 Dry Powder Mixer

Function:

Completely mix the raw materials and additives into ideal mixing effect.

Feature:

1. The spiral belt wear resistant steel, has a long service life;

2. It is backed by wheel drive settings, to prevent shaft breaking;

3. The motor reducer adopts direct type, stable quality, energy saving and environmental protection.

04 2nd Screw Conveyor

Function:

Conveying materials to the finished product hopper.

Feature:

1) The spiral blade adopts wear-resistant steel;

2) The patent sealing device to prevent the bearings into the dust.

1) The spiral blade adopts wear-resistant steel;

2) The patent sealing device to prevent the bearings into the dust.

05 Simple Dust Collector

Function:

Collect dust more effectively.

Features: Separation of impurities.

Features: Separation of impurities.

06 Finished Product Hopper

Function:

To store the finished product,

and equipped with automatic vibration device to ensure that materials can enter the packaging

system quickly

.

07 Packing Machine

Function:

Intelligently pack the finished products in bags.

Alternatives:

1.Valve bag packing machine;

2.Open bag packing machine;

3.Ton bag packing machine;

4.Bulk packing machine.

1.Valve bag packing machine;

2.Open bag packing machine;

3.Ton bag packing machine;

4.Bulk packing machine.

Application Fields

Simple small dry mortar production line (also known as simple dry mortar plant, small putty production line) can be used for the production of the following products.

1. Bonding mortar, such as tile binder, gap filler, tile grout.

2. Rendering mortar, such as inner and outer rendering mortar, paint putty, coloring.

3. Decorative mortar, insulation mortar, etc.

4. Masonry mortar, ordinary masonry mortar, concrete masonry mortar, AAC brick masonry mortar, etc.

5. Floor mortar, such as ordinary floor mortar, self-leveling mortar, etc.

6. Special mortar, such as repair mortar, waterproof mortar, flexible anti-crack mortar, etc.

Case poster

Hot Searches