- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V/110V

-

Power:

-

80

-

Dimension(L*W*H):

-

Customized Design

-

Weight (KG):

-

550

-

Application:

-

Surface Treatment

-

Keywords:

-

Complete Set

-

After Warranty Service:

-

Video Technical Support Online Support

-

Advantage:

-

Stable

-

Technology:

-

Advanced

-

Function:

-

metal surface treatment

-

Spraying method:

-

HVOF spray

-

After-sales Service Provided:

-

1 year

-

Package:

-

Wooden Package

-

Power supply:

-

3 Phases

Quick Details

-

Machine Type:

-

surface coating machine, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Coating Equipment, Other

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

guagnzhou sanxin

-

Voltage:

-

380V/220V/110V

-

Power:

-

80

-

Dimension(L*W*H):

-

Customized Design

-

Weight (KG):

-

550

-

Application:

-

Surface Treatment

-

Keywords:

-

Complete Set

-

After Warranty Service:

-

Video Technical Support Online Support

-

Advantage:

-

Stable

-

Technology:

-

Advanced

-

Function:

-

metal surface treatment

-

Spraying method:

-

HVOF spray

-

After-sales Service Provided:

-

1 year

-

Package:

-

Wooden Package

-

Power supply:

-

3 Phases

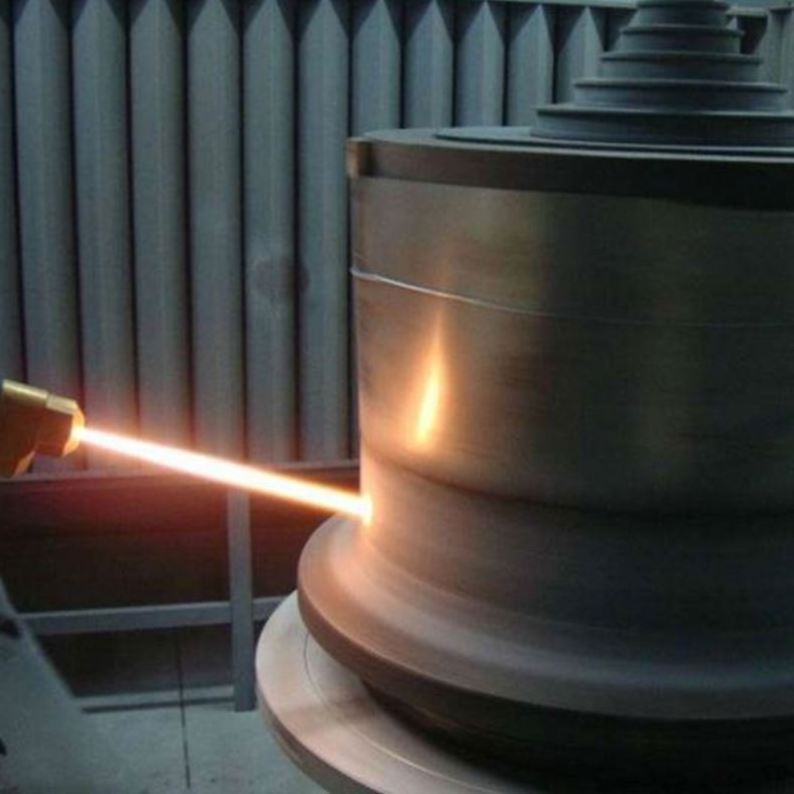

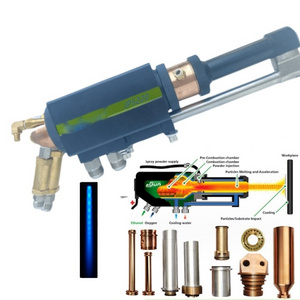

HVOF Flame Spraying Euqipment

This series of HVOF Spraying equipment is designed for thermal spraying Metal, Alloy and Ceramic coating to surface treatment process. It can apply for small parts, large workpiece coating or spraying, Mechanical Spraying, project construction spraying or coating the Metal, Oxide, Alloy, Carbide, Nitride, Boride and Complex powders. The HVOF spraying Line consists of Spraying Gun, Control Cabinet, Powder feeder, and Water Chiller and also required joint pipes.

HVOF Flame Spraying Equipment Parameters:

|

HVOF spray equipment |

SX- -5000 gas fuel HVOF |

BP-6000 Kerosene HVOF |

||

|

coating material |

WC,Ni-Cr chrome carbide etc |

WC,Ni-Cr chrome carbide etc |

||

|

Fuel |

Oxygen & Propane |

oxygen & kerosene |

||

|

powder feeding gas |

Nitrogen or Argon |

Nitrogen or Argon |

||

|

airflow parameter |

pressure |

flow |

pressure |

flow |

|

fuel |

0.65Mpa |

88L/min |

1.2Mpa |

15-24L/min |

|

oxygen |

11Mpa |

305L/min |

1.6Mpa |

800-1500L/min |

|

powder feeding gas |

0.8-1.2Mpa |

18L/min |

1.2Mpa |

18L/min |

|

powder feeding velocity |

160g/min |

180g/min |

||

|

Powder coating size |

15-45μm |

10-45μm |

||

|

Coating Strength |

>60MPa |

>80MPa |

||

|

Spraying speed |

2700℃ |

3000℃ |

||

|

PLC control |

Siemens brand |

Siemens brand |

||

|

Compressor |

Dual drive, American Copeland |

|||

Spraying Coating Application : Cookware, Textile Machinery, Steel, Petrochemical, Electricity, Farm Machinery, Heavy Machinery, Paper Making machinery, New Energy (Lithium Battery, Hydrogen production), Precious Metal, Artificial Medicine, Bearing, Aerospace, Military, University Research Institute

Our Services

1.Upon customer request,we can dispatch one or two technicians to customer's factory for commisioning.

2.We can supply the vedio of installation and commisioning for equipment and also guide customer how to operate until equipment working in good condition.

3.Support customer dispatch their technician to come to our factory for free learning of equipment operation.

We can also supply the coating processing service

Wear-resistant,High temperature tesistance,Anti-corrosion,Insulation,Magnetic inductive,Self-lubricating,Wear sealing,Anti-stick and wear-resistant,repair coating.

Packaging & Shipping