- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

Huazhan

-

Model Number:

-

Wear-resistant Pipe

-

Name:

-

Ceramic Wear-resistant Straight Pipe

-

Keyword:

-

Wear-resistant Steel Pipe

-

Diameter:

-

68-630mm

-

Wall Thickness:

-

8-10mm

-

Wear-resistant Layer Thickness:

-

4-6mm

-

Application:

-

Electric power, steel, metallurgy, mining, coal, cement and ect

-

Color:

-

Customized Colors

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Round

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

Huazhan

-

Model Number:

-

Wear-resistant Pipe

-

Name:

-

Ceramic Wear-resistant Straight Pipe

-

Keyword:

-

Wear-resistant Steel Pipe

-

Diameter:

-

68-630mm

-

Wall Thickness:

-

8-10mm

-

Wear-resistant Layer Thickness:

-

4-6mm

-

Application:

-

Electric power, steel, metallurgy, mining, coal, cement and ect

-

Color:

-

Customized Colors

Huazhan

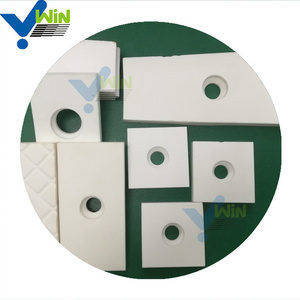

Ceramic Wear-resistant Straight Tube

Products Description

Composite ceramic steel pipe is a new type of composite material with international advanced level that was successfully developed and industrialized in the national "863" high-tech technology plan.

The product is manufactured by the self-propagating high-temperature synthesis method (SHS), which uses the aluminothermic reaction to exothermicly melt the reactants, and separates Al2O3 and Fe under the action of centrifugal force.

The composite tube is corundum ceramic (AL2O3) layer from the inside to the outside, Transition layer and steel pipe layer. The corundum ceramic layer is a dense corundum ceramic formed at a high temperature above 2000 ℃to form a firm metallurgical bond with the steel pipe through the transition layer.

Feature:

It has good corrosion resistance, wear resistance, high strength, toughness, and strong resistance to mechanical shock and thermal shock. comprehensive performance. And can carry out turning, grinding and welding and other processing. So far, no composite material has such excellent comprehensive properties.

|

Ceramic-lined composite straight tube parameters

|

|

|

|

|

|

|

|

|||||||

|

Number

|

pipe diameter

|

pipe wall thickness

|

Wear-resistant layer thickness

|

Number

|

pipe diameter

|

pipe wall thickness

|

Wear-resistant layer thickness

|

|||||||

|

1

|

68

|

8

|

4

|

18

|

168

|

8

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

10

|

4

|

|||||||

|

2

|

70

|

8

|

4

|

19

|

180

|

8

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

10

|

4

|

|||||||

|

3

|

73

|

8

|

4

|

20

|

194

|

8

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

10

|

4

|

|||||||

|

4

|

76

|

8

|

4

|

21

|

203

|

8

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

10

|

4

|

|||||||

|

5

|

83

|

8

|

4

|

22

|

219

|

10

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

12

|

5

|

|||||||

|

6

|

89

|

8

|

4

|

23

|

245

|

10

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

12

|

5

|

|||||||

|

7

|

95

|

8

|

4

|

24

|

273

|

10

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

12

|

5

|

|||||||

|

8

|

102

|

8

|

4

|

25

|

299

|

10

|

4

|

|||||||

|

|

|

10

|

4

|

|

|

12

|

5

|

|||||||

|

9

|

108

|

8

|

4

|

26

|

325

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

10

|

114

|

8

|

4

|

27

|

351

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

11

|

121

|

8

|

4

|

28

|

377

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

12

|

127

|

8

|

4

|

29

|

402

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

13

|

133

|

8

|

4

|

30

|

426

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

14

|

140

|

8

|

4

|

31

|

480

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

15

|

146

|

8

|

4

|

32

|

500

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

16

|

152

|

8

|

4

|

33

|

530

|

12

|

5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

17

|

159

|

8

|

4

|

34

|

630

|

12

|

5.5

|

|||||||

|

|

|

10

|

4

|

|

|

14

|

6

|

|||||||

|

|

|

|

|

|

|

|

||||||||

Application:

Ceramic-steel composite pipes have been widely used in electric power, steel, metallurgy, mining, coal, cement and aluminum casting industries. The use of power plant coal powder, ash and mine tailings, iron ore powder transportation, mine backfilling, etc. shows that its service life is longer than Ordinary steel pipes are more than 10 times higher.

Product Packaging

Hot Searches