- Product Details

- {{item.text}}

Quick Details

-

Cutting Area:

-

1500mmX3000mm / 2000mmX4000mm

-

Cutting Thickness:

-

0.5-40mm

-

Control Software:

-

Cypcut/Cyptube

-

Place of Origin:

-

China

-

Brand Name:

-

OPTIC

-

Weight (KG):

-

2700 KG

-

Core Components:

-

All

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Function:

-

Cutting Metal Materials

-

Type:

-

Fiber Lasr Cutting

-

Laser source:

-

Raycus IPG NLIGHT Laser Source

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Power supply:

-

380V/50HZ

-

Control system:

-

Cypcut Control System

-

Laser head:

-

Raytools

Quick Details

-

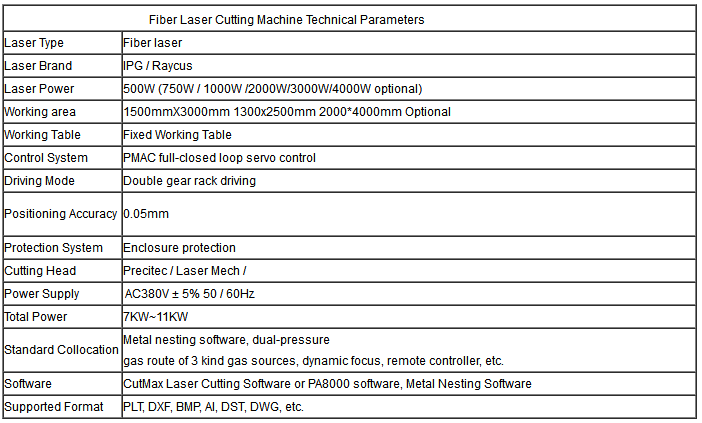

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

0-40000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Cutting Area:

-

1500mmX3000mm / 2000mmX4000mm

-

Cutting Thickness:

-

0.5-40mm

-

Control Software:

-

Cypcut/Cyptube

-

Place of Origin:

-

China

-

Brand Name:

-

OPTIC

-

Weight (KG):

-

2700 KG

-

Core Components:

-

All

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Function:

-

Cutting Metal Materials

-

Type:

-

Fiber Lasr Cutting

-

Laser source:

-

Raycus IPG NLIGHT Laser Source

-

Working area:

-

1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm

-

Power supply:

-

380V/50HZ

-

Control system:

-

Cypcut Control System

-

Laser head:

-

Raytools

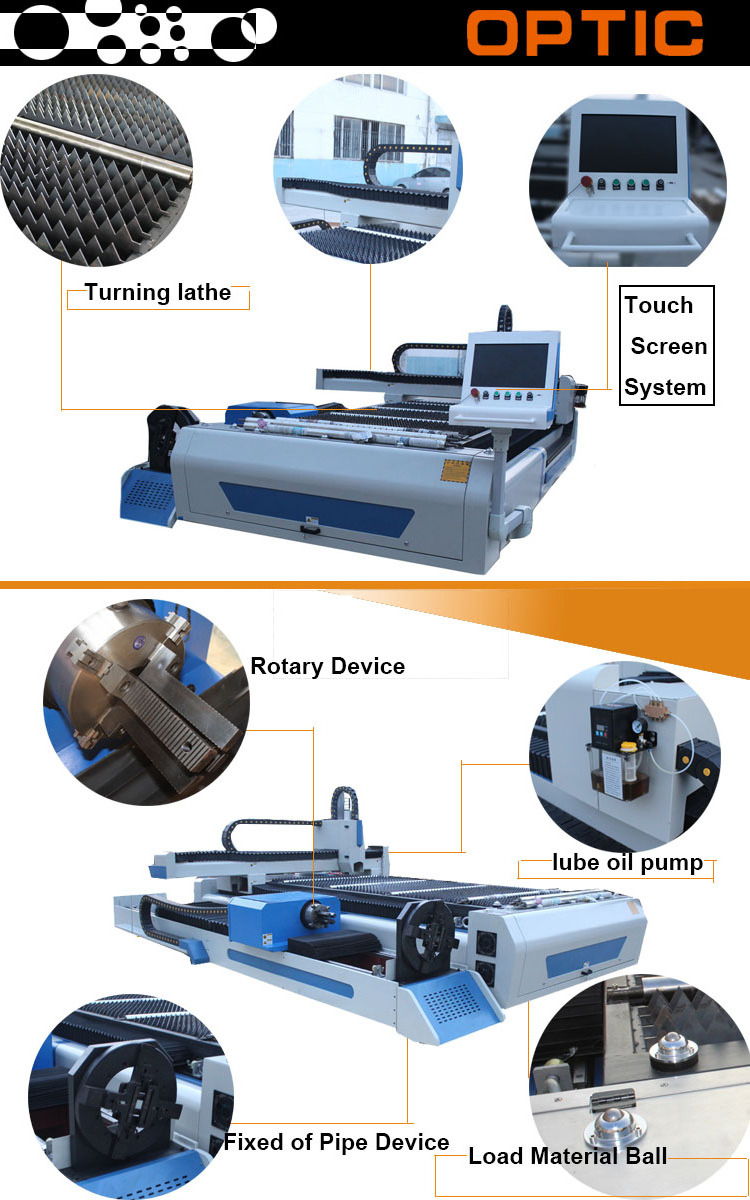

China Shenzhen manufactory Plate and pipe laser die cutting machine for hot sale

Fiber Laser Cutting Machine Advantages

1) Fiber laser cutting is the fastest process for thin sheet metal.

2) A “clean cut” surface quality is obtained.

3) Reflective materials like aluminium,copper and brass can be cut with ease.

4) Parts process cost is very low.

5 ) Little to no maintenance costs.

6) Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long periods. There are no other consumable costs.

7) Resonator life is over 100,000 working hours.

8) Double ball screw close-loop system and imported open-type CNC system, ensure high accuracy and high working efficiency during high speed cutting.

9) Standard collocation of 2KW fiber laser and optional 500W-4000W fiber laser Standard collocation of 500W fiber laser and optional 1000W IPG or N-light fiber. Low operating and maintenance costs. Achieve long-term return on investment and revenue maximization.

10) Enclosure design conforms to CE standard for reliable and safe processing. Pallet changer is convenient for material uploading and unloading, improving efficiency.Open structure is easy and convenient for material uploading and unloading.Drawer collecting device makes receiving materials more convenient.

Cutting thickness as reference :

500W: 3mm stainless steel, 6mm carbon steel.

750W: 4mm stainless steel, 8mm carbon steel

1000W:6mm stainless steel, 10mm carbon steel

2000W:8mm stainless steel, 20mm carbon steel

2000w-4000w are the high laser power,suitable for thick metal materials cutting