- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/400V/415V/450V

-

Power:

-

240KW

-

Certification:

-

CE ISO

-

Application:

-

Chips/Fries

-

Name:

-

Frozen French Fries Processing Line

-

Material:

-

304 Stainless Steel

-

Dry material:

-

content≥20%

-

Sugar:

-

content≤0.4%

-

Length:

-

≥68mm

-

Dimensions:

-

5500*2000*2000mm

-

Heating method:

-

electric

Quick Details

-

Brand Name:

-

TUNE

-

Weight:

-

1500Kg

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V/380V/400V/415V/450V

-

Power:

-

240KW

-

Certification:

-

CE ISO

-

Application:

-

Chips/Fries

-

Name:

-

Frozen French Fries Processing Line

-

Material:

-

304 Stainless Steel

-

Dry material:

-

content≥20%

-

Sugar:

-

content≤0.4%

-

Length:

-

≥68mm

-

Dimensions:

-

5500*2000*2000mm

-

Heating method:

-

electric

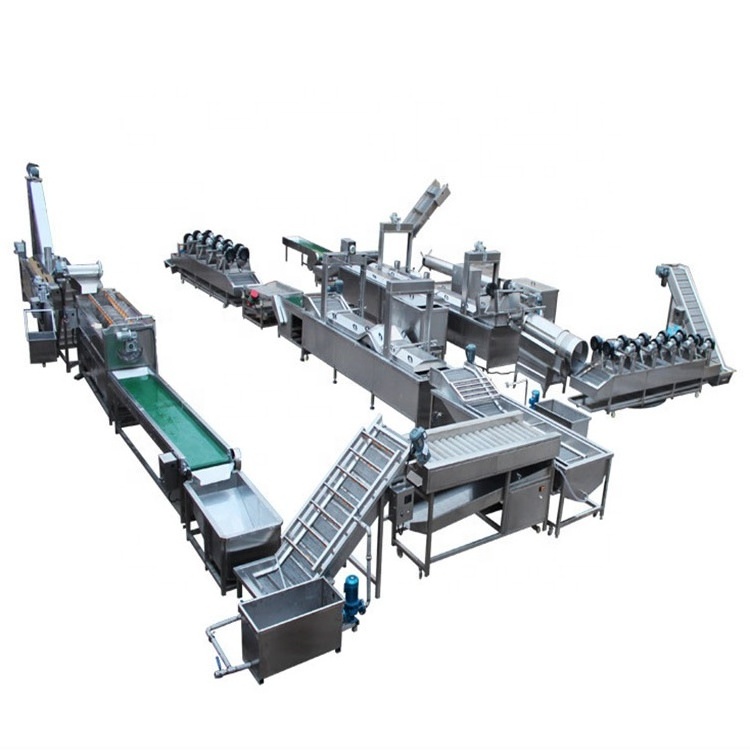

Frozen French Fries Production Line Machine

This fully automatic potato fries production line is mainly composed of potato washing & peeling machine, cutting machine, blanching machine, dehydrator, frying machine, deoiling machine, flavour machine and packing machine. Easy operation, high output and good production effect.French fries seem very smooth and uniform. Besides,the thickness could be adjusted freely. Apart from making potato fries, you could also make Frozen French Fries(equipped with IQF Tunnel Freezer).

The frozen French fries production line process includes: cleaning. Peel. Slices, cleaning, impurities removal, blanching,air-drying, Pre-frying, air-drying, Quick-frozen, packaging.Then store in cold storage. Capacity also can do 100kg, 200kg , 300kg, 500kg,1000kg output One hour.

The Plantain Chips production line process includes: Slices, Frying ,Sugar dipping, second frying,air drying seasoning,packaging.Capacity also can do 50kg, 100kg , 200kg, 300kg output One hour.

The potato chips production line process includes: cleaning. Peel. Slices, cleaning, blanching, air-drying, Frying, air-drying,seasoning, packaging.Capacity also can do 50kg, 100kg , 200kg, 300kg output One hour.

Potato Requirement

Oval in shape Dry material content≥20% Sugar content≤0.4%;

Length ≥68mm Color outside is yellow Color inside is whiteLess and small bud hole

Equipment Description

1. Hoister with water spray

It is used to preclean potato,soften the potato skin, then hoist potatoes into washing and peeling machine.This machine is used to peeling potatoes with hard brush and emery brush; Uneven and corrugated brush can peel the potatoes completely.

3. Inspecting table

This machine is used to pick out potato eyes and dark parts on potatoes by manually. There will be waste material holes and unpeeled potatoes return system.

4. Water bucket elevator

This machine is used to preclean potato, soften the potato skin, then hoist potatoes into washing and peeling machine.

5. Potato cutter

This machine is used to cut potato into sticks, french fries quality depends on fries length and shape, so cutting machine is very important.

6. Rinsing machine

This machine used to washing potato starch and protect potato from oxidation, keep its original color.

7. Blanching machine

This machine is used to deactivate the activity of the oxidase, take off the starch, separate out the reducing sugar, also after blanching,it will get inner soft taste of french fries.

8. Vibration de-water machine

Used to remove water.Also have many holes at the end of machine to leak out small part and waste part potato.

9. Air-dryer machine:Remove water, drying fries

11. Vibrating de-oil machine:This machine is used to de-oil with the vibrating.

12. Cooling line:Use fan to blow off the water on stick surface, then deliver sticks into the freezer.

13. Conveyor :Used between cooling line and quick-freezing machine.

14. Fluidized-type freezer

It is used to quick freezing the french fries in short time, fries center temperature at -18 ℃, Can the maximum keep the original flavor and product quality.

15. Conveyor:Used between quick-freezing machine and packing machine.

16. Automatic weighing and packing machine

It is used to pack the frozen french fries automatically, including bucket Elevator.

|

1:Hoister

|

2400x700x1600mm

|

10:Air-dryer machine

|

6000x1100x1600mm

|

|

2:Washing&peeling machine

|

3400x900x1500mm

|

11:Hoister

|

1800x800x1300mm

|

|

3:Inspecting table

|

4000x800x900mm

|

12:Continuous frying line machine

|

6000x1200x2400m

|

|

4:Potato cutter

|

950x800x950mm

|

13:Oil filter

|

400x400x800mm

|

|

5:Water bucket elevator

|

2400*800*1500mm

|

14:Vibration de-oil machine

|

1800x1000x1200mm

|

|

6:Miscellaneous machine

|

3000x1000x1300mm

|

15:Drying line

|

6000x1100x1600mm

|

|

7:Rinsing line machine

|

4000x1200x1400mm

|

16:Hoister

|

3000x800x2000mm

|

|

8:Blanching line machine

|

6000x1200x1400mm

|

17:IQF Tunnel Freezer

|

8000x3900x2900mm

|

|

9:Vibration de-water machine

|

1800x1000x1200mm

|

18:Automatic weighing and packing machine

|

3000x3000x2600mm

|