- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

5.5 kw

-

Dimension(L*W*H):

-

10*1.5*3.5m

-

Weight (KG):

-

1000

-

Product name:

-

rice husk dryer

-

Yield:

-

400-500kg/h

-

the moisture content before drying:

-

40%

-

Production line:

-

crusher, ball mill, carbonization furnace , pellet mill etc

-

Supply:

-

factory supply directly

-

OEM:

-

acceptable

-

Energy consumption:

-

low

-

Operation:

-

smooth and stable

-

Structure:

-

advanced and reasonable

-

Weight:

-

1500 kg

Quick Details

-

Type:

-

Hot Air Furnace

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Voltage:

-

380v

-

Power:

-

5.5 kw

-

Dimension(L*W*H):

-

10*1.5*3.5m

-

Weight (KG):

-

1000

-

Product name:

-

rice husk dryer

-

Yield:

-

400-500kg/h

-

the moisture content before drying:

-

40%

-

Production line:

-

crusher, ball mill, carbonization furnace , pellet mill etc

-

Supply:

-

factory supply directly

-

OEM:

-

acceptable

-

Energy consumption:

-

low

-

Operation:

-

smooth and stable

-

Structure:

-

advanced and reasonable

-

Weight:

-

1500 kg

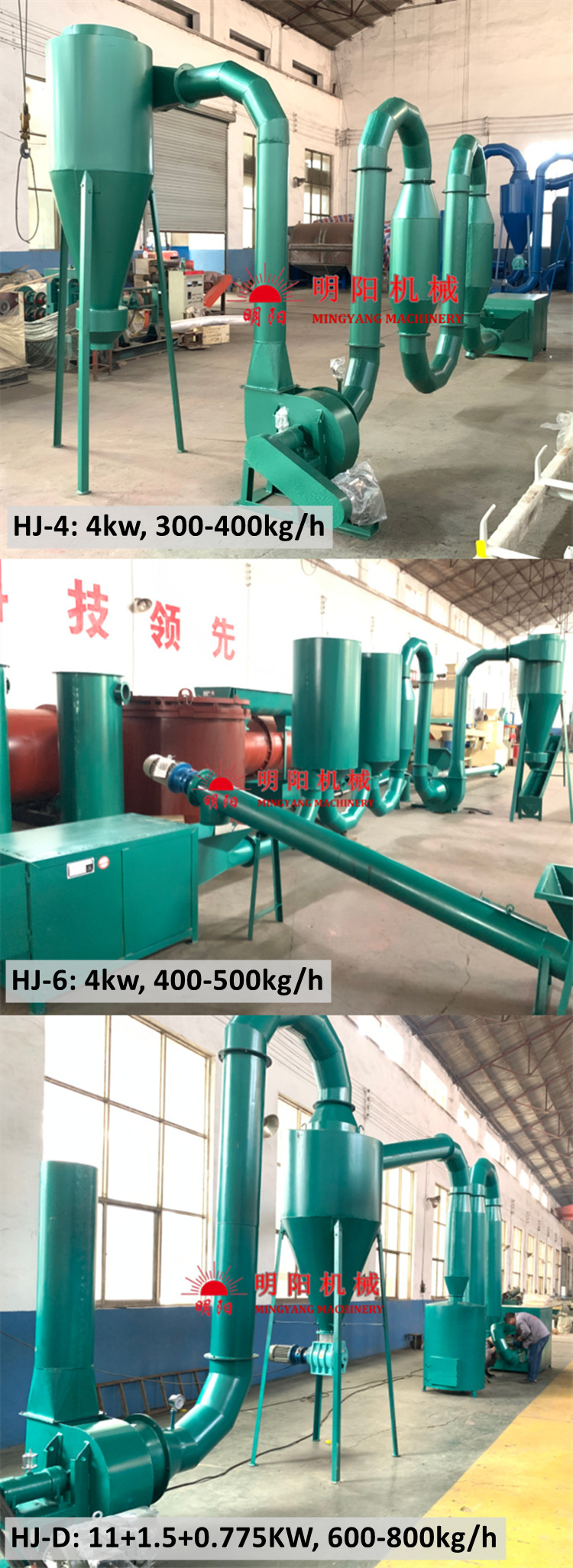

No pollution rice husk dryer wooden powder drying equipment sawdust drier

Simple description of the rice husk dryer:

rice husk dryer can dry the materials mainly using the hot wind produced by the hot blast stove, the machine is applied to the material in dispersed state which contains high moisture humidity, such as the saw dust, grainor straw. If the moisture is very high and the output demand is very big, we can use the two drier together, the materials can lose a lot of moisture through the firs outlet of the first drier.

Structure of the rice husk dryer:

The drier is consisted of hot wind stove(ready by customer), screw feeder, buffer, blower, the pipe sand cyclone. The work process is that the air flow is formed through the negative pressure of blower, the materials enter into the pipe through the screw feeder, so that the hot wind and materials mix together, and the moisture is seperated from the materials when passing the cyclone. At last, the material are dried.

Working basis of the rice husk dryer:

1. The wet materials are put into the hopper. Then the fuel boiler generates hot air which mixes with wet materials and then is sucked into the pipes by the exhausted blower (draft fan) quickly.

2. The hot air is going to through the curving pipes, thus wet materials can get fully dried during the drying process.

3. After the wet materials get dried, the dried materials are expelled out by the exhausted blower.

Parameters of the rice husk dryer:

| Model | Power | Capacity | The moisture content before drying | Weight |

| HJ-4 | 4kw | 300-400kg/h | 35% | 1000kg |

| HJ-6 | 4kw | 400-600kg/h | 40% | 1500kg |

| HJ-8 | 11kw | 600-1000kg/h | 40-50% | 2500kg |

1. Make sure the material size is within 3-5mm, If not in this scope, choose one kind of crusher is necessary according to your raw material;

2. Make sure the material moisture content is within 8-12%, If not in this range, it's necessary to use one drying machine according to your raw material moisture content

3. Finished the two steps below, this step is to make the wod briqquette machine which under high temperature and pressure and use the screw propreller and heating ring and forming tube to make the briquette. The briqquette can be square, pentagon and hexagon. So please tell me first which shape you prefer;

4. This step is to make charcoal briquette by using the carbonization. And the charcoal briquette is widely used in many fields, such as BBQ, home heating, industrial boiler etc with high heating value. So this is your best choice to choose this line.