Q1:Can you accept OEM?

A1: Yes, we can. We had 12years OEM experience.

Q2:Can you make a general proposal for us if we have no technical engineer?

A2: Yes, sure. We can offer the professional suggestions and proposal design

for you freely.

Q3: How long is the delivery time?

A3: Most simple and standard type is 10- 30days after receive deposit, non-standard

design depends on per order.

Q4: How about your machine quality control ?

A4: 48 hours testing before the shipment, there is a specialized quality control engineer

to check the processing quality for each step and strictly obey the ISO,CE rules.

Q5:Are you manufacture company or trade company?

A5: We are pure manufacture.

Q6:How about price?

A6:We have our own factory and can give you the competitive price. Besides,

we have a policy that " for saving time and absolutely honest business attitude,

we quote as low as possible, discount can be given according to quantity".

Q7:What is your payment terms?

A7:T/T or L/C; by T/T 30% as down payment, 70% by T/T before delivery, L/C at sight.

Q8:What is the workshop size required?

A8:The production line Can be put in straight line and also can change the direction according to

your factory size.We can design the layout according to your factory size.

Q9: Can I mix different models in one container?

A9: Yes, different models can be mixed in one container, but the quantity of each model should

not be less than MOQ.

Q10: What is your warranty terms?

A10: We offer different warranty time for different products. Please contact with us for detailed

warranty terms.

Potato cleaning and peeling machines offer several advantages in commercial food processing settings:

1. Time-saving: Cleaning and peeling potatoes by hand can be a time-consuming task, especially when dealing with large quantities. Potato cleaning and peeling machines can process a significant number of potatoes in a short amount of time, saving labor and increasing productivity.

2. Consistent Results: These machines are designed to clean and peel potatoes uniformly, ensuring consistent results. This is particularly important for commercial operations where consistent quality is crucial for customer satisfaction.

3. Increased Efficiency: Potato cleaning and peeling machines are designed to remove dirt, debris, and outer skin efficiently. They can handle a large volume of potatoes in a continuous process, reducing the need for manual labor and increasing overall efficiency.

4. Reduced Labor Costs: By automating the cleaning and peeling process, you can reduce the need for manual labor. This can lead to significant cost savings in terms of wages and employee training.

5. Improved Hygiene: Potato cleaning and peeling machines are typically designed with hygiene in mind. They are made of food-grade materials and are easy to clean and sanitize, reducing the risk of contamination and ensuring food safety.

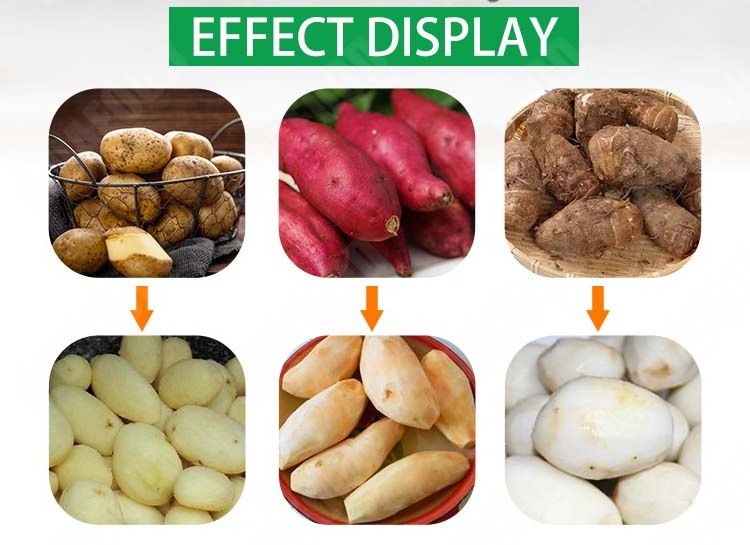

6. Versatility: Some potato cleaning and peeling machines are adjustable and can handle different sizes and varieties of potatoes. This versatility allows you to process various types of potatoes without the need for additional equipment.

7. Minimized Waste: These machines are designed to remove only the outer skin of the potatoes, minimizing waste compared to manual peeling methods. This can help reduce food costs and improve overall efficiency.