- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1680*1160*2330mm

-

Max. Grinding Diameter:

-

202mm

-

Max. Grinding Length:

-

202mm

-

Certification:

-

ISO9001

-

Power:

-

6kw

-

Weight:

-

1750kg

-

Color:

-

White

Quick Details

-

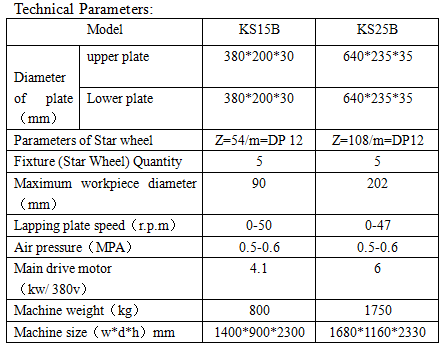

Model Number:

-

KS25B

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KIZI

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1680*1160*2330mm

-

Max. Grinding Diameter:

-

202mm

-

Max. Grinding Length:

-

202mm

-

Certification:

-

ISO9001

-

Power:

-

6kw

-

Weight:

-

1750kg

-

Color:

-

White

KIZI provides the most efficient and reliable solutions for flat lapping and polishing of components utilized in medical,mechanical seals, ceramic,automotive optical,photonic,MEMS,wafer and compound semi-conductor applications and other industrial markets.

Series B double-sided lapping machine

Usage:

This machine is mainly for double-sided lapping and polishing of hard, fragile materials like metal and non-metal ones,especially for optical glass, crystals, quartz wafer,sapphire glass, lithium niobate,gallium arsenide, ceramic chips, ferrite, silicon wafer, valve plate, friction plate, stain sealings, cylinder piston ring, oil pump vane .

Features:

1.The use of Japanese "SMC" pneumatic components gains segmentation precision pressure control, which is suitable for coarse grinding, mill grinding, fine grinding and polishing technic.

2.

The use of touch-screen interface, Swiss “ABB” and PLC program control system

ensures the stability and safety of the machine and the system is compatible with grating thickness control system with best resolution of 0.001mm.

3. Usage of Japanese “NSK”spindle shafting achieves precision and durability of the machine.

4. The operation would be more convenient since one handle can control the fast and slow rising and descending of upper plate.

5.Unique safety retaining mechanism could prevent the emergency of plate falling caused by accident expiration and power failure.

6.

Unique automatic floating positioning device

fo upper plate reduces the trouble caused by staggering and proofreading dics.

7.

Ring gear and the retaining plate semi-automatic lifting system

not only gives convenience to place and take workpiece and occlusal gear, but also could change the cruise to meet the matching requirement of high and low positions.

8.

The operation of the whole machine drived by mono motor

, which makes perfect match for upper plate, lower plate , center wheel and speed. The cruise achieves forward and reversal and meets the demand of disc repair technic.

1. Factory with competative price,high quality and stability

2. R&D Dep. with 20 technicians, 5 of them in decades experience

3. Free charge of customer sample making

4. Completed After sales service and expertise support from Taiwan

1. Company

2.Workshop

3.Lab

4.Our exhibition

Packing Details : Packing, 1pcs/carton

Delivery Details : Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: No, we could not offer the machine sample for free charge but

can provide free proofing for the customer.