Protective lens protect focal lens avoid damage

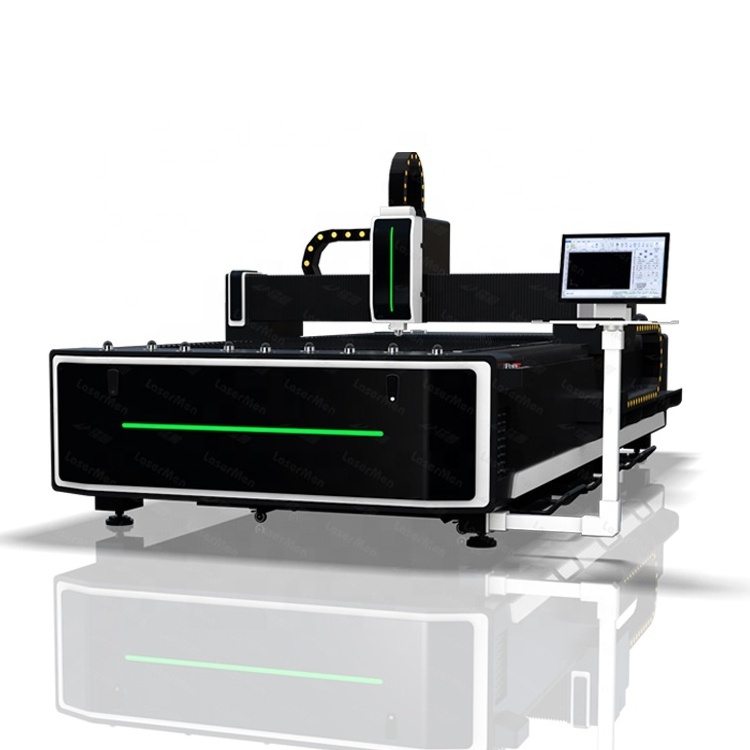

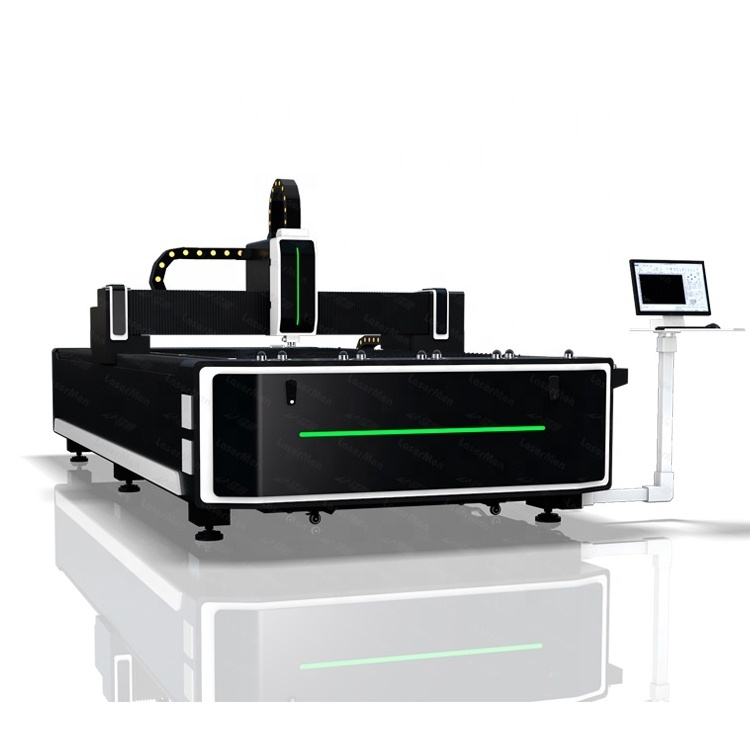

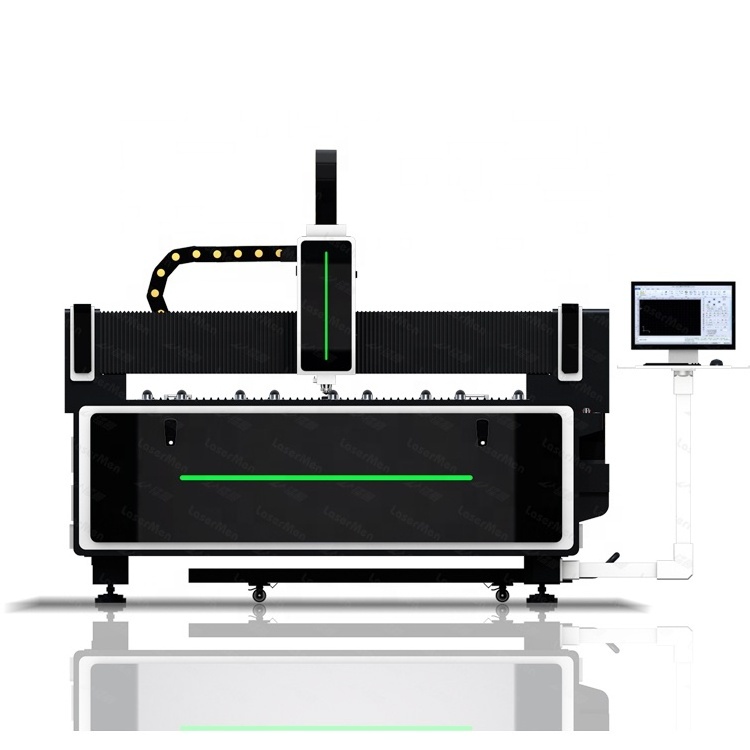

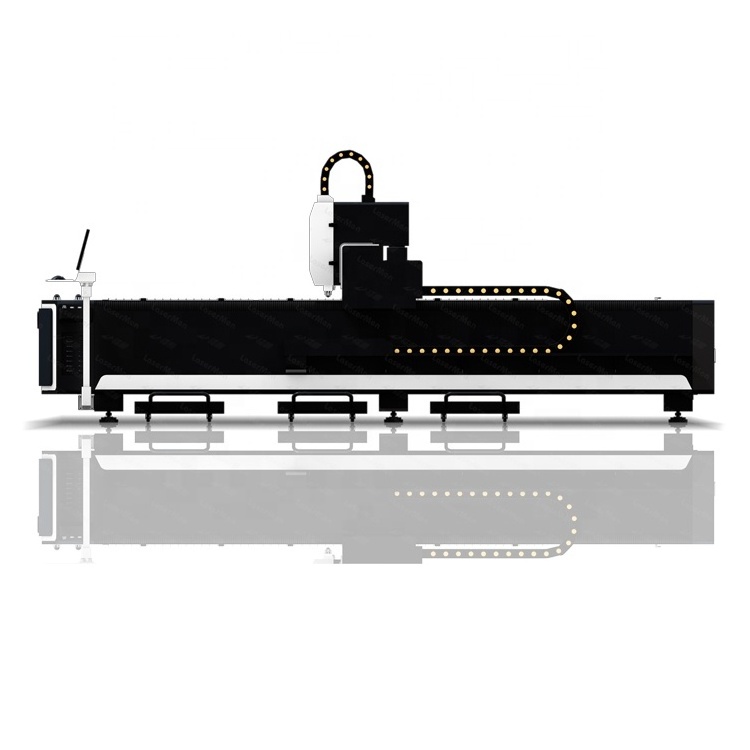

- Product Details

- {{item.text}}

Quick Details

-

Cutting Area:

-

1500mm x 3000mm

-

Cutting Thickness:

-

Depends on materials

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lasermen (LM)

-

Weight (KG):

-

2800 KG

-

Core Components:

-

fiber laser generator

-

Name:

-

carbon steel fiber laser cutting machine

-

Laser power:

-

1000W

-

Machine table:

-

Saw-shape machine table

-

Driving system:

-

Japan servo motors and drivers

-

Working Voltage:

-

380 V± 10% / 50Hz

-

Work Motor:

-

Japan sevro motor

-

Transmission:

-

Gear rack and square guide rail

-

Cooling system:

-

industrial water chiller

-

Control system:

-

CypCut

-

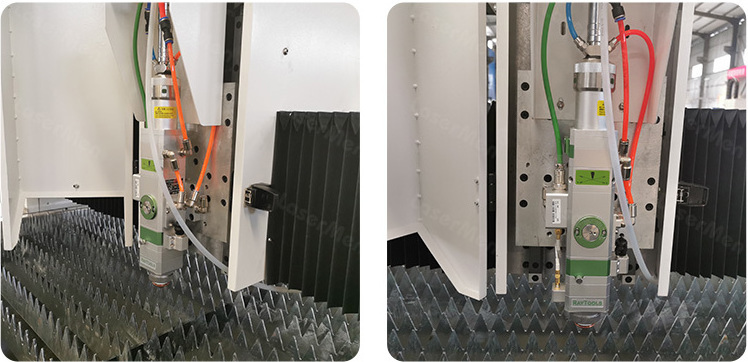

Laser head:

-

Raytools laser head

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

60000mm/min

-

Cooling Mode:

-

WATER COOLING

-

Cutting Area:

-

1500mm x 3000mm

-

Cutting Thickness:

-

Depends on materials

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lasermen (LM)

-

Weight (KG):

-

2800 KG

-

Core Components:

-

fiber laser generator

-

Name:

-

carbon steel fiber laser cutting machine

-

Laser power:

-

1000W

-

Machine table:

-

Saw-shape machine table

-

Driving system:

-

Japan servo motors and drivers

-

Working Voltage:

-

380 V± 10% / 50Hz

-

Work Motor:

-

Japan sevro motor

-

Transmission:

-

Gear rack and square guide rail

-

Cooling system:

-

industrial water chiller

-

Control system:

-

CypCut

-

Laser head:

-

Raytools laser head

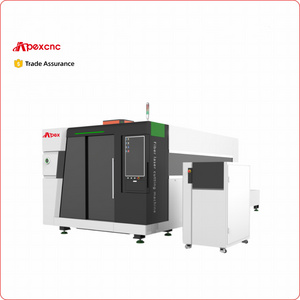

Bottom price Lasermen brand carbon steel fiber laser cutting machine

|

Machine models

|

LM-1530AF

|

|

Working area

|

1500*300mm

|

|

Fiber laser power

|

1000W (1500W/ 2000W / 3000W / 4000W / 6000W are optional)

|

|

Min. Line width

|

0.1mm

|

|

Positioning accuracy

|

0.01mm

|

|

Max. cutting speed

|

30m/min

|

|

Driving mode

|

Servo motors and drivers

|

|

Transmission mode

|

Precise dual gear rack transmission

|

|

Cutting capacity

|

Depending on laser power and material

|

|

Assisting gas

|

Compressed air, oxygen and nitrogen

|

|

Working voltage

|

220V / 380V

|

|

Machine weight

|

2500kgs

|

|

Working condition

|

5-35℃

|

|

Cooling mode

|

Industrial circulation water cooling

|

|

Wavelength

|

1080mm

|

|

Visual positioning

|

Red dot

|

|

Continuous working hours

|

24 hrs

|

Main Features

1.Professional laser cutting control system has the advantages of precise, stable, easy to use (able to layout graphics and pierce fast).

2.Gear rack transmission, double servo motors and drivers in Y, with accelerated speed up to 0.8G, ensures machine high speed as we as high precision.

3.High rigidity heavy machine body, minimizes the vibration during high speed cutting.

4.Adopt top brand fiber laser source, excellent laser beam, stable laser output, and precise cutting.

5.Use Taiwan rails, with higher precision and longer service time.

JPT brand fiber laser source, China famous, more reliable

2. Special wavelength (1080nm), unique ability to cut high-reflective materials, such as aluminum, copper and brass, etc.

3. Electro-optical conversion rate of the laser >25%, much more efficient than that of CO2 laser (<10%), greatly reducing power consumption.

4. Laser transmission through fiber, no transmission loss.

5. Modular design, "plug and play", mini size, easy installation, no maintenance of laser and beam transmission system.

6. Pumping source service life> 100,000

7. Precise quality of laser beam with pretty small divergence angle.

Professional laser cutting head

Laser cutting head is with Z axis height adjuster. The laser head is with capacitive sensing to automatically, stably and rapidly adjust the laser head height during cutting, which ensures it cutting with the same and the best focal length all the time even if the metal sheet is not flat.

A variety of nozzle designs are available to match with different focal length lenses. The laser head can be equipped with different optical lenses which are with different focal length. The focal length and nozzle height can be flexibly adjusted.

The cutting head focal length adjustment precision is 0.01mm.

Laser is invisible, there is red dot showing laser spot position on material.

Raytools protective lens

S&A brand CWFL-1000 is specially applied for cooling 1000w fiber, CWFL-1500 is for 1500w fiber, CWFL-2000 is for 2000w fiber.

S&A brand professional water chiller can be able to cool the fiber laser and optic lenses at the same time, multiple use for saving cost, space and manual move, quite convenient for the user. S&A industrial water chiller is popular for its 2 temperature control modes as constant temperature and intelligent temperature control. Under intelligent mode, the water temperature is adjusted according to ambient temperature. Customers no longer need to worry about the water temperature adjustment of seasonal changes.

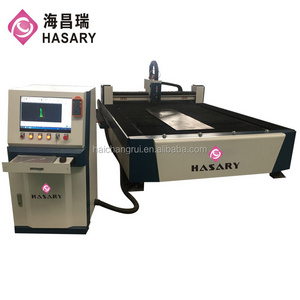

Control system

CypCut laser cutting control system integrates file reading, design, output, and processing control. It's able to complete the entire process from design to processing. The software, installed in an industrial computer, provides a wealth of laser cutting processing parameters, flexible layout and cutting path editing capabilities. Cypcut Control system and software in English language, supporting files: DXF, PLT, AI, LXD, etc. Drawing in the software is ok. Software is with fly cutting mode for cutting same products to save time. The nesting function automatically arranges graphs to leave minimum spaces and save materials.

Transmission system

Machine is with gear rack and linear rail transmission, which ensures machine high speed movement, precision and stability as well. 2 gear racks and 2 rails (25mm width) in Y; 1 gear rack and 2 rails (20mm width) in X. The transmission system is protected by dust shields.

Driving system

We use Japanese YASKAWA servo motors and drivers. Machine X is driven by a 850W motor, Y is driven by two 850W motors, and Z (laser head auto focusing) is driven by a 400W motor.

Auto lubrication

Pressing the handle above the oil box, it automatically lubricate guide rails, which ensures the machine keep moving smoothly and with good precision.

Exhaust fan

Exhaust channel is accessible within the whole machine table range. A 2.2Kw exhaust fan strongly removes the smells and dusts caused by cutting

Gas assist controller

Gas assists cutting either in cutting speed, cutting thickness or cutting effect. For example, oxygen helps to cut faster and thicker; nitrogen helps to get brighter cutting edge. The solenoid valve controls the gas blowing. Gas blows only during cutting, which saves your gas cost.

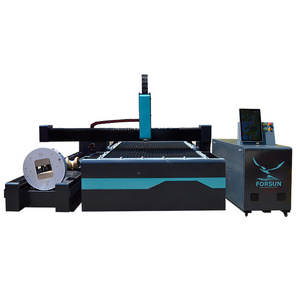

Machine table

Saw-shape machine table

holds metal sheets steady with little touch with metal sheet. The saws are thick and durable. In front and both sides of machine table, there are

rolling balls

for assisting sheets loading.

Operation system

The operation system is user-friendly. Software installed in English language. There are 2 USB flash ports for files import. It can be disassembled to make smaller packing sizes, and easy to install.

The remote control provides fast and convenient operation.

Single nozzle, Concentrated blowing Nitrogen, is suitable for cutting thin metal, such as stainless steel, aluminum and brass, etc

Double nozzle, Evenly blowing Oxygen, is suitable for cutting thick metal, such as carbon steel, etc

Application

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, automobile, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgy equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, and other fields. Professional used to cut sheet metal like carbon/mild steel, stainless steel, aluminum alloy, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminum zinc plate, etc.