- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.02%

-

CrO Content (%):

-

0.01%

-

SiC Content (%):

-

85%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

RBTSC

-

Brand Name:

-

Robert

-

Size:

-

Customers' Requirement

-

Sample:

-

Available

-

Application:

-

Non-ferrous Metal Smelting, Steel

-

Fe2O3:

-

0.1%-0.3%

-

HS Code:

-

28492000

-

Refractoriness Under Load @0.2MPa:

-

1700℃

-

Cold Crushing Strength:

-

80MPa

-

Bulk Density:

-

2.6g/cm3

-

Apparent Porosity:

-

10%

-

Thermal conductivity:

-

8-15(W/m.k)

Quick Details

-

SiO2 Content (%):

-

10%

-

Al2O3 Content (%):

-

0.10%

-

MgO Content (%):

-

0.02%

-

CaO Content (%):

-

0.02%

-

CrO Content (%):

-

0.01%

-

SiC Content (%):

-

85%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

RBTSC

-

Brand Name:

-

Robert

-

Size:

-

Customers' Requirement

-

Sample:

-

Available

-

Application:

-

Non-ferrous Metal Smelting, Steel

-

Fe2O3:

-

0.1%-0.3%

-

HS Code:

-

28492000

-

Refractoriness Under Load @0.2MPa:

-

1700℃

-

Cold Crushing Strength:

-

80MPa

-

Bulk Density:

-

2.6g/cm3

-

Apparent Porosity:

-

10%

-

Thermal conductivity:

-

8-15(W/m.k)

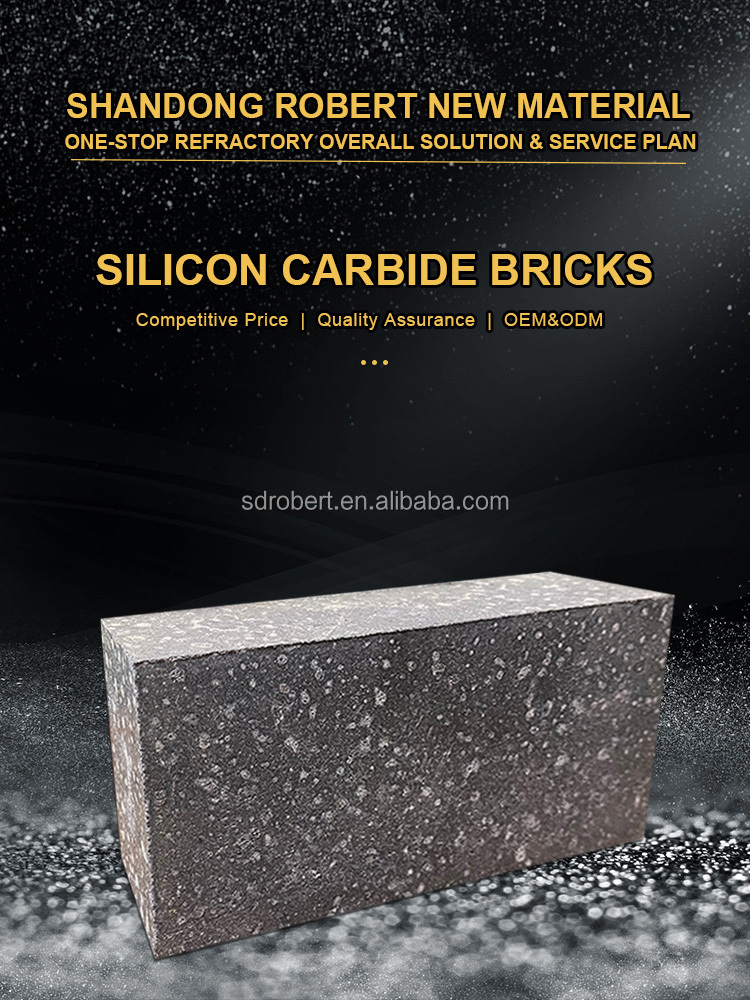

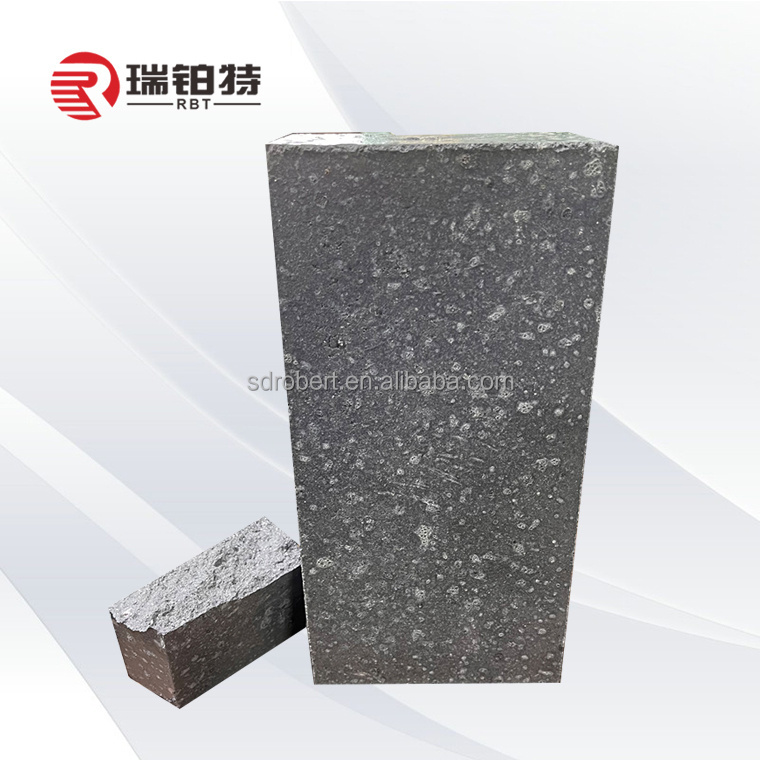

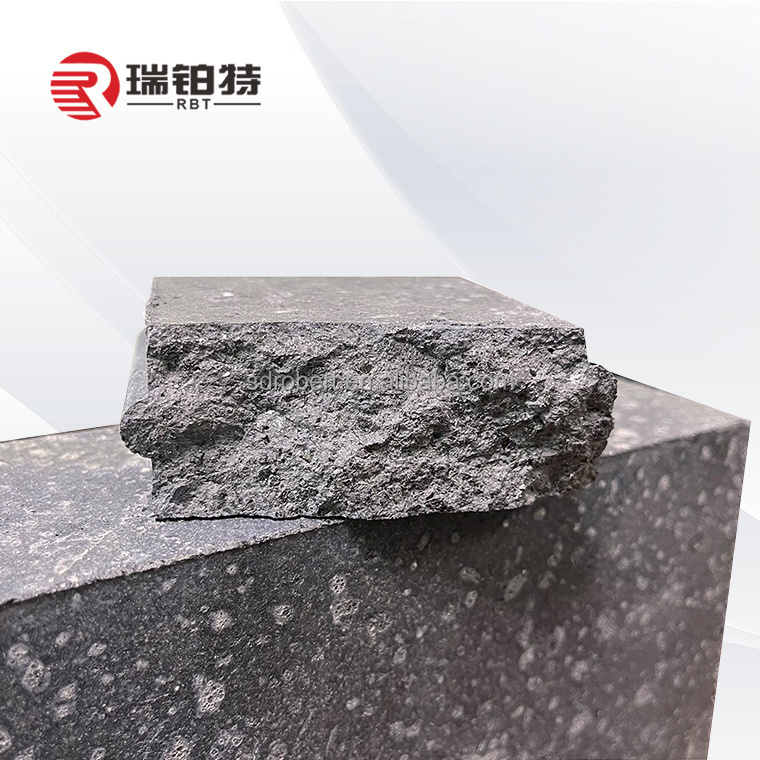

Product Description

Silicon carbide bricks

is a refractory material made of SiC as the main raw material. Mohs hardness is 9. It is relatively stable to acidic slag. It contains 72% to 99% SiC. It is divided into

clay-bonded, Si3N4-bonded, Sialon-bonded, β-SiC-bonded, Si2ON2-bonded and recrystallized silicon carbide bricks

. It is mainly used to make non-ferrous metallurgical retorts, aluminum casting molds, electric furnace linings and heat exchangers.

Features

1. Excellent oxidation resistance

2. Thermal shock stability

3. Compact structure

4. High temperature volume stability

5. High temperature flexural strength

2. Thermal shock stability

3. Compact structure

4. High temperature volume stability

5. High temperature flexural strength

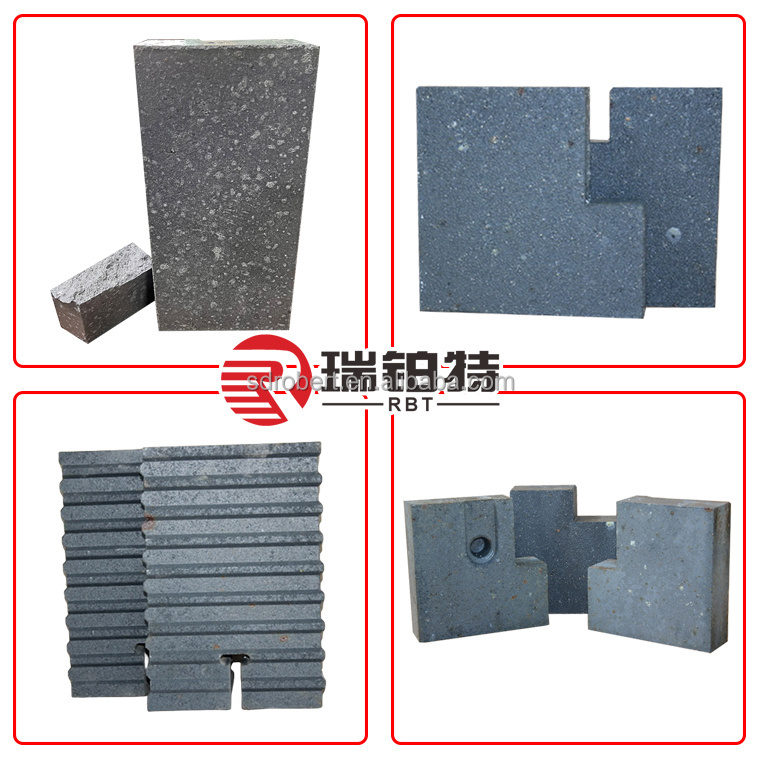

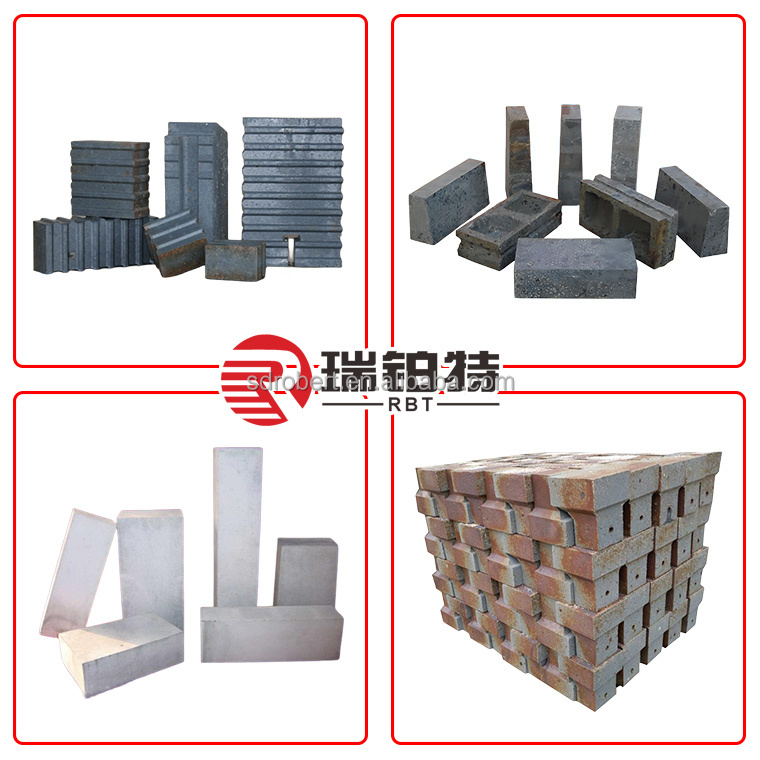

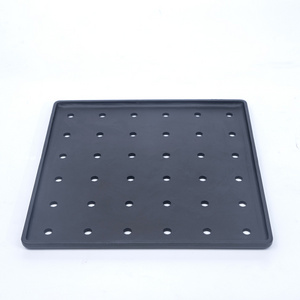

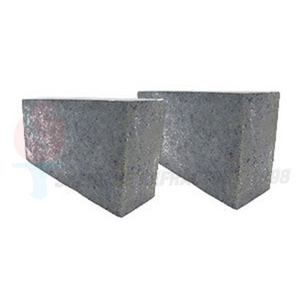

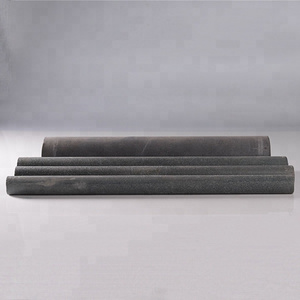

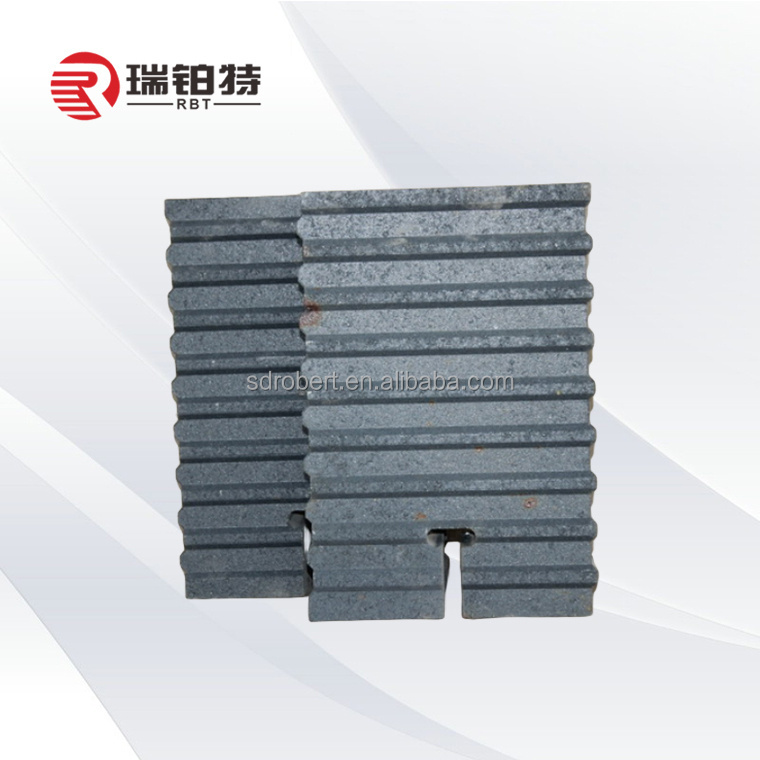

Details Images

Standard Bricks

Standard Bricks

Special Shaped Bricks

Special Shaped Bricks

Special Shaped Bricks

Special Shaped Bricks

Special Shaped Bricks

Special Shaped Bricks

Special Shaped Bricks

Special Shaped Bricks

Si3N4-bonded S

ilicon Carbide Bricks

Product Index

|

INDEX

|

RBTSC

|

|

Refractoriness(℃) ≥

|

1750

|

|

Bulk Density(g/cm3) ≥

|

2.60

|

|

Apparent Porosity(%) ≤

|

10

|

|

Cold Crushing Strength(MPa) ≥

|

80

|

|

Thermal conductivity(W/m.k)

|

8-15

|

|

Refractoriness Under Load@ 0.2MPa(℃) ≥

|

1700

|

|

SIC(%) ≥

|

85

|

|

SiO2(%) ≥

|

10

|

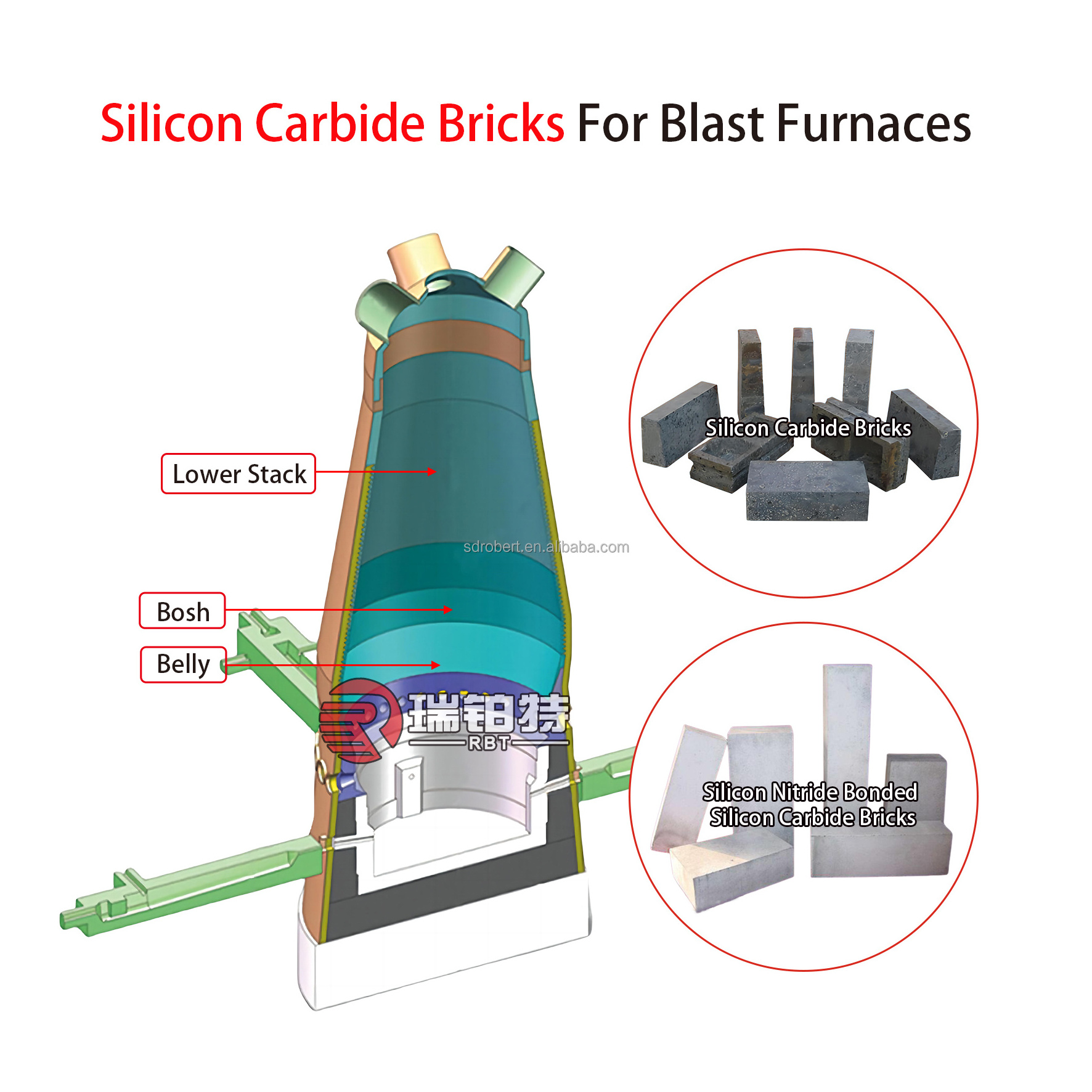

Applications

1. Can be used in metallurgical steel drum linings, nozzles, plugs, blast furnace bottoms and bosses, water-cooled slide rails in heating furnaces;

2. Non-ferrous metal smelting stills, distillation tower trays, side walls of electrolyzers, smelting metal crucibles;

3. Silicic acid shelf boards and flameproof materials for salt industry kilns;

4. Oil and gas generators and organic waste combustion furnaces in the chemical industry;

5. Kiln furniture for high-tech ceramics, aluminum electrolytic cell linings, molten aluminum conduits, and kiln furniture for ceramic kilns, large and medium-sized blast furnaces lower body, furnace waist and belly, aluminum refining furnace lining, zinc distillation tank lining, etc.

Blast Furnace

Ceramic Kiln

Rotary Kiln

Chemical Industry

Package&Warehouse

Hot Searches