- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GNS, GNS

-

Model Number:

-

G44

-

Type:

-

Acetic

-

Tack-free:

-

≤9 min

-

Storage temperature:

-

+5°C to +25°C

-

Application:

-

Installing, fixing insulating of door and window frames

-

Curing time:

-

≤24 hrs

-

Packing:

-

24 pcs/ctn

-

Certificate:

-

ISO 9001: 2008

-

Component:

-

One component Silicone Sealant

-

Storage life:

-

9 months

-

OEM:

-

Avliable

Quick Details

-

CAS No.:

-

9009-54-5

-

Other Names:

-

silicone sealant

-

MF:

-

Mixture

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GNS, GNS

-

Model Number:

-

G44

-

Type:

-

Acetic

-

Tack-free:

-

≤9 min

-

Storage temperature:

-

+5°C to +25°C

-

Application:

-

Installing, fixing insulating of door and window frames

-

Curing time:

-

≤24 hrs

-

Packing:

-

24 pcs/ctn

-

Certificate:

-

ISO 9001: 2008

-

Component:

-

One component Silicone Sealant

-

Storage life:

-

9 months

-

OEM:

-

Avliable

GNS G44 TVS & Butt Joint Silicone Sealant

Product Description

GNS G44 is a one part, high performance silicone sealant with ultimate tensile strength, mechanical properties for curtain wall, Total Vision System (TVS) and architectural applications. It has very good weathering resistance, durability, sealing and bonding properties.

Typical Use

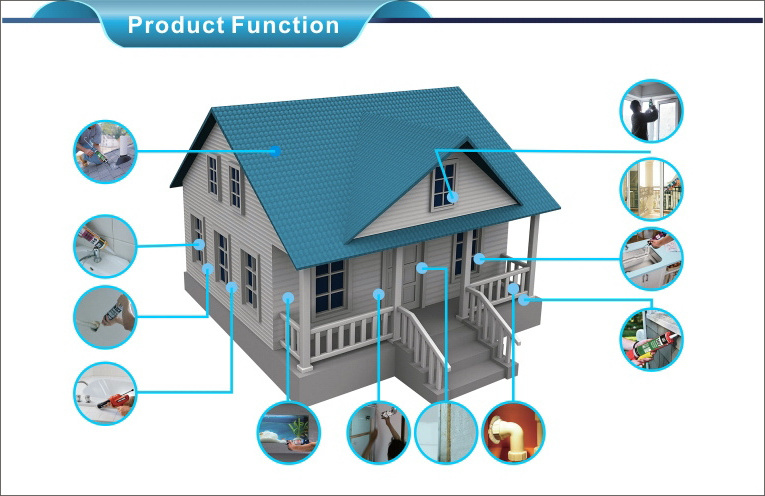

For Total Vision System (TVS).

Aquarium, big fish tank and general decorative usages.

Skylinghts, canopies and general glazing.

For butt-joints and corner joints.

For special architectural glazing.

Non-oily wood and some other construction materials.

Application

Apply to clean ,dry and grease-free surfaces. Cut the nozzle at 45°angle to the desired shape and size. Screw nozzle on the cartridge. Place cartridge in the caulking gun. Apply sealant into the base of the joint so that it can completely fill the joint. Tool the surface of the joint immediately after sealant application to provide a smooth even finish and ensure the sealant wets both sides of the joint. Remove the masking tape after tooling. Do not disturb the joint for 48 hours. Avoid contact with various cleaning agents for solvents (e.g. bleach) whilst sealant is curing.

PERFORMANCE DATA

|

Test Parameter |

Unit |

Result |

|

As Supplied Tested at 23 ℃ and 50% RH |

||

|

Specific Gravity |

g/ml |

0.99±0.02 |

|

Flow (sag or slump) |

mm |

0 |

|

Extrusion Rate Skin Time |

ml/minute minute |

130 5~10 |

|

Tack-free Time |

hour |

≤1.0 |

|

Curing time (5mm) |

hour |

≤8 |

|

As Cured-after 21 days at 23 ℃ and 50% RH |

||

|

Durometer Hardness, Shore A |

Points |

30 |

|

Movement Capability |

% |

± 25 |

|

Tensile/Modulus at 50% Elongation |

Mpa |

0.32 |

|

Tensile/Modulus at 100% Elongation |

Mpa |

0.38 |

|

Ultimate Tensile Strength Ultimate Elongation at Break |

Mpa % |

0.45 300 |