- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

220 - 580 mm

-

Ejector Stroke(mm):

-

150 mm

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

570 cm³

-

Injection Rate (g/s):

-

218 g/s

-

Injection Weight (g):

-

518 g

-

Screw Speed (rpm):

-

1 - 195 rpm

-

Screw diameter (mm):

-

55 mm

-

Screw L/D Ratio:

-

21

-

Distance between Tie Bars:

-

575x525 mm

-

Weight (KG):

-

7300

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

492 mm

-

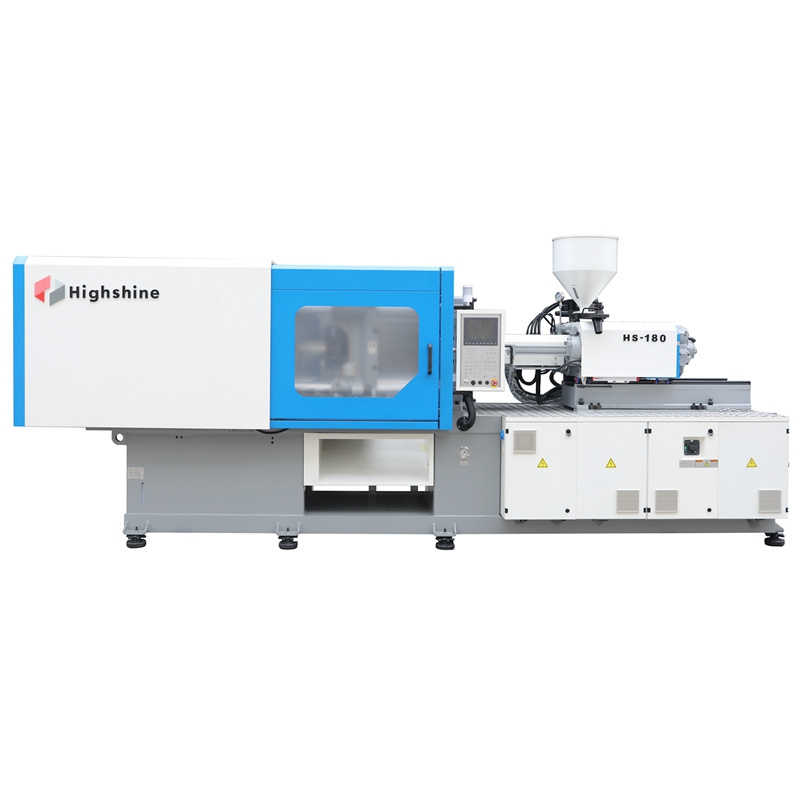

Model Number:

-

HS Series

-

Brand Name:

-

HighShine

-

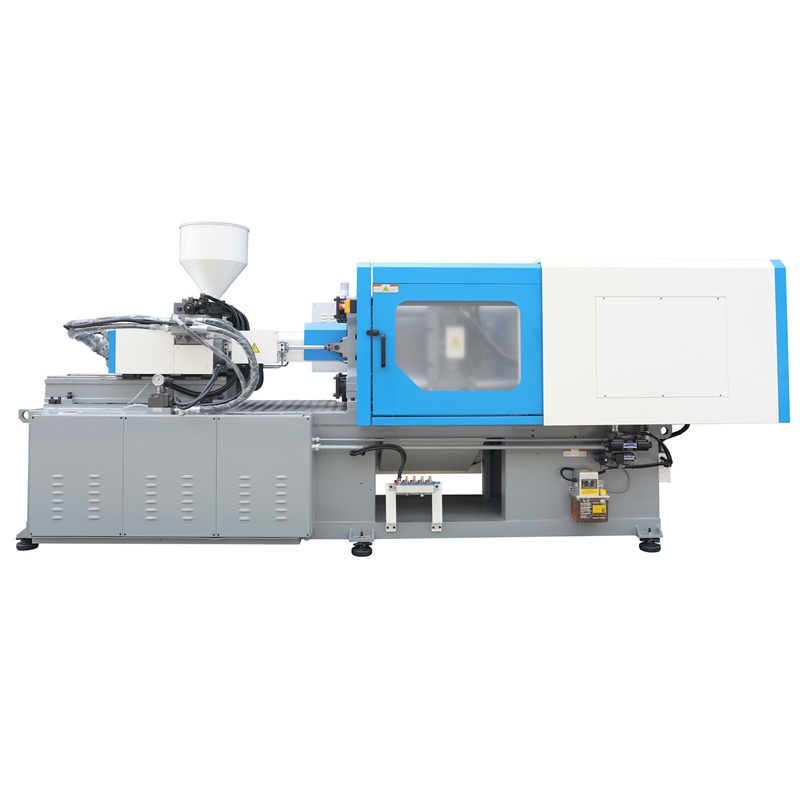

Power (kW):

-

45 kW

-

Product Name:

-

Plastik Enjeksiyon

-

Certification:

-

CE

-

Marketing Type:

-

Hot Sale 2021

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

575mm

-

Distance between Tie Bars(Height)(mm):

-

525mm

-

Plasticizing Capacity(g/s):

-

250

-

Mold Height(mm):

-

220 - 580 mm

-

Ejector Stroke(mm):

-

150 mm

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

570 cm³

-

Injection Rate (g/s):

-

218 g/s

-

Injection Weight (g):

-

518 g

-

Screw Speed (rpm):

-

1 - 195 rpm

-

Screw diameter (mm):

-

55 mm

-

Screw L/D Ratio:

-

21

-

Distance between Tie Bars:

-

575x525 mm

-

Weight (KG):

-

7300

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

492 mm

-

Model Number:

-

HS Series

-

Brand Name:

-

HighShine

-

Power (kW):

-

45 kW

-

Product Name:

-

Plastik Enjeksiyon

-

Certification:

-

CE

-

Marketing Type:

-

Hot Sale 2021

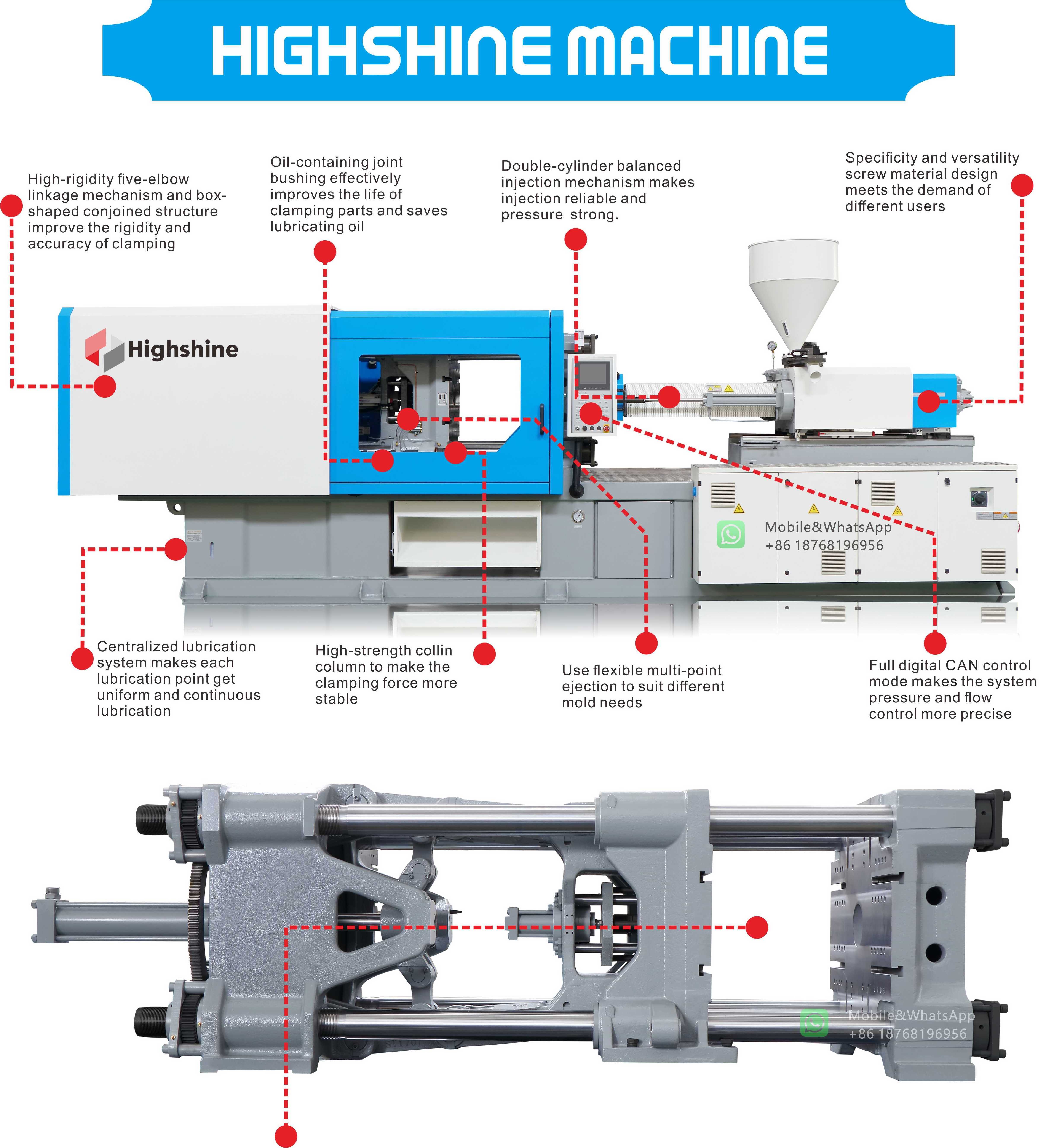

Plastik Enjeksiyon

Contact: Kevin Kong

Mobile/Whatsapp: +8618768196956

Promotion for All orders decided within 10 days:

Free bimetallic screw

Free double linear rails

Free Core Pulling Valve

Free Air Blow Valve

Free Euromap 12/67 Robotic Arm Socket

Available Machine Models:

|

HIGHSHINE

HS INJECTION MOLDING MACHINE |

|||

| Model List |

Clamping

Tonnage |

Distance Between

Tie Bar (HxV) |

Shot weight

(gram) B SCREW |

| UNIT | ton | mm | g |

| HS-110 | 110 | 420X370 | 148 |

| HS-150 | 150 | 470X420 | 252 |

| HS-180 | 180 | 530X470 | 325 |

| HS-220 | 220 | 575X525 | 446 |

| HS-250 | 250 | 575X525 | 518 |

| HS-280 | 280 | 630X580 | 721 |

| HS-350 | 350 | 730X680 | 1225 |

| HS-420 | 420 | 780X730 | 1508 |

| HS-550 | 550 | 880X830 | 2168 |

| HS-650 | 650 | 925X875 | 2774 |

| HS-750 | 750 | 980X950 | 2966 |

| HS-900 | 900 | 1125X1085 | 3574 |

| HS-1200 | 1200 | 1180X1100 | 4805 |

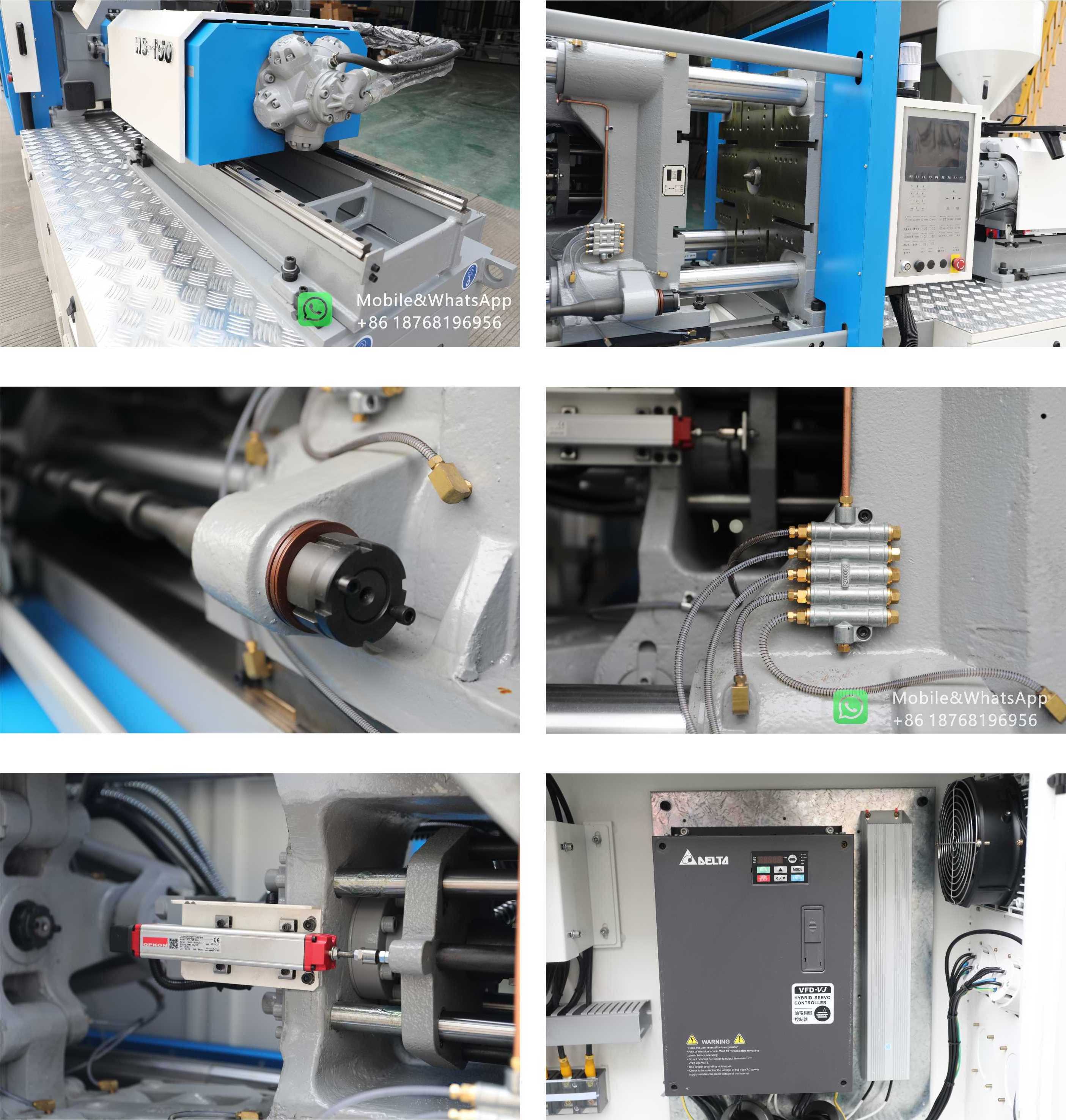

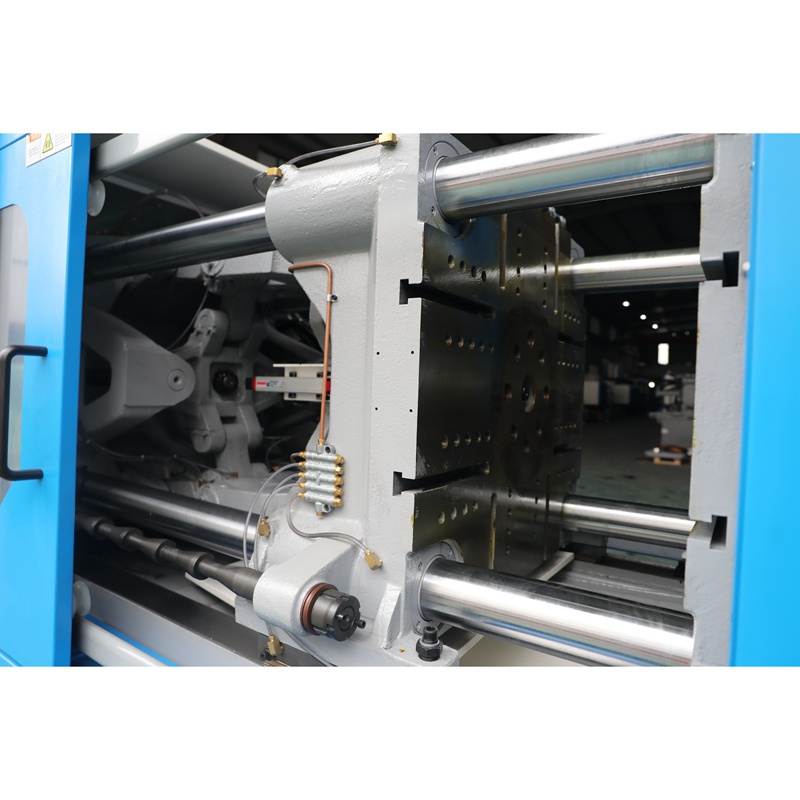

1). Larger space between tie-bars, suitable for larger molds and multi-cavity production demand.

2).

Extended and widened guide support, higher repeataccuracy, stabler movement, smaller deformation, greatly improve product quality and mold service life.

3).

Upgraded parts, Graphite-copper bushes and slider used on tie-bar, ejector and movable platen, ensure faster and preciser mold close and open.

4).

Better designed mechanical structure and toggle system, faster cycle time, and improve production efficiency. European type ejector structure, larger space, much more convenient for maintenance.

5).

Prepared enough space for upgrade and retrofits.

6).

Built-in and adjustment free mechanical safety bar, more safe and convenient.

7).

Much higher rigidity mechanical system than normal Chinese IMM, not only improve machines using-life, but also can protect mold.