- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

LeadWorld

-

Dimension(L*W*H):

-

can be customized

-

Weight:

-

1600 KG

-

Product name:

-

Collaborative Robot Palletizer

-

Speed:

-

12PPM

-

Max Load:

-

30KG

-

Power supply:

-

200-240V 50/60Hz

-

Air Comsumption:

-

0-55℃

-

Material:

-

Aluminum

-

Specification:

-

3950*1724mm

-

Pallet Size:

-

1250*1250mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware, Cigarettes, Tobacco

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood

-

Voltage:

-

200-240V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

LeadWorld

-

Dimension(L*W*H):

-

can be customized

-

Weight:

-

1600 KG

-

Product name:

-

Collaborative Robot Palletizer

-

Speed:

-

12PPM

-

Max Load:

-

30KG

-

Power supply:

-

200-240V 50/60Hz

-

Air Comsumption:

-

0-55℃

-

Material:

-

Aluminum

-

Specification:

-

3950*1724mm

-

Pallet Size:

-

1250*1250mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

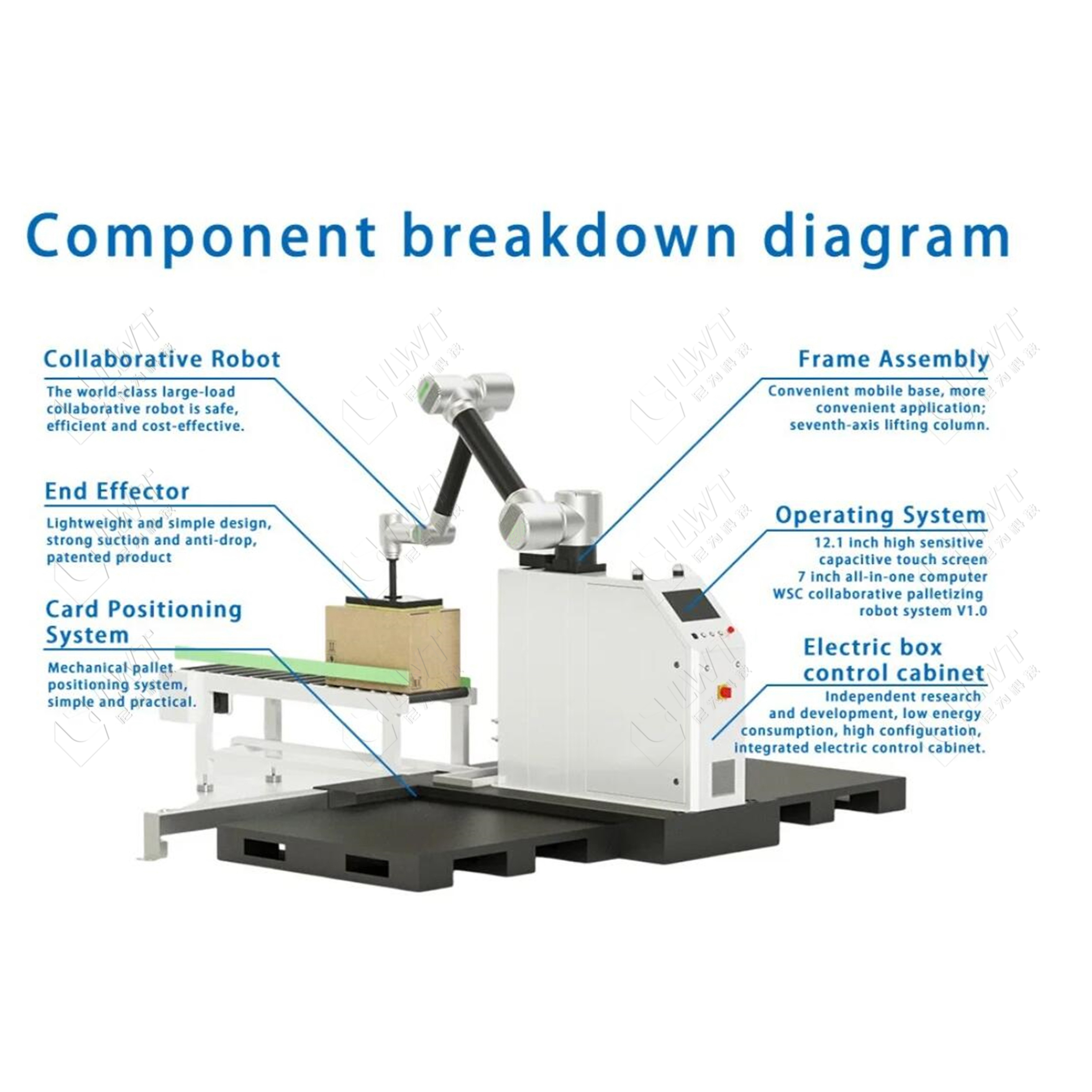

Products Description

The palletizing robot is an organic combination of machinery and computer programs. It provides higher production efficiency for modern production. Stacking machines are widely used in the stacking industry. The palletizing robot greatly saves labor and space. The palletizing robot operates flexibly and accurately, is fast and efficient, has high stability, and has high work efficiency.

The palletizing robot system adopts a patented coordinate robot, which occupies a flexible and compact installation space. The idea of being able to build an efficient and energy-saving fully automatic block molding machine production line within a small footprint has become a reality.

The palletizing robot system adopts a patented coordinate robot, which occupies a flexible and compact installation space. The idea of being able to build an efficient and energy-saving fully automatic block molding machine production line within a small footprint has become a reality.

|

Item No.

|

LW-RP165

|

LW-RP210

|

|

Palletizing Height

|

1650mm(Including Pallet)

|

2100mm(Including Pallet)

|

|

Speed

|

12PPM

|

12PPM

|

|

Max Load

|

30KG

|

30KG

|

|

Power Supply

|

200-240V 50/60Hz

|

200-240V 50/60Hz

|

|

Air Comsumption

|

400NL/MIN

|

400NL/MIN

|

|

Temperature Range

|

0-55ºC

|

0-55ºC

|

|

Base style:

|

Installation Base

|

Lifting Base

|

|

Material

|

Aluminum

|

Aluminum

|

|

Communication Type

|

EtherCAT

|

EtherCAT

|

|

Control/PLC

|

Keba

|

Keba

|

|

HMI

|

Keba

|

Keba

|

|

Reducer

|

Nidec

|

Nidec

|

|

Specification

|

3950*1724mm

|

3950*1724mm

|

|

Pallet Working Radius

|

1600mm

|

1600mm

|

|

Pallet Size

|

1250*1250mm

|

1250*1250mm

|

|

Positioning Accuracy

|

±0.04mm

|

±0.04mm

|

|

Safety

|

Safety Fence, Light Curtain(Optional, Recommend Make it local)

|

Safety Fence, Light Curtain(Optional, Recommend Make it local)

|

Collaborative palletization redefines the concept of“'ease of use”:

Installation and re-adjustment can be completed within 2 hours

New path set-up within 5 minutes.

8-10 boxes can be stacked per minute.

Up to 800 stacking paths can be set.

New path set-up within 5 minutes.

8-10 boxes can be stacked per minute.

Up to 800 stacking paths can be set.

300mmx1200mm。Maximum tray size1300mmx1200mm

Two products can be stacked simultaneously.

With label orientation function.

Two products can be stacked simultaneously.

With label orientation function.

Advantages

Simple programming

Visual programming is simple and efficient, and ordinary employees can easily manipulate robots without having to master the programming language.The programming mode can be learned in half an hour and simple programming can be completed in 1 hour.

Safety and stability

Industrial grade force-sensor with high reliability and safety;

Visual programming is simple and efficient, and ordinary employees can easily manipulate robots without having to master the programming language.The programming mode can be learned in half an hour and simple programming can be completed in 1 hour.

Safety and stability

Industrial grade force-sensor with high reliability and safety;

Support 10-level collision detection and sensor safety detection;

without loss of safety function in case of single fault;

Flexible deployment

Integrated design, light and flexible, small footprint area;

without loss of safety function in case of single fault;

Flexible deployment

Integrated design, light and flexible, small footprint area;

Workstation deployment of new task setting is simple,quick and efficient;

Flexible Production

With fast switching of various functional scenarios,flexible production can be realized by human-machine cooperation,

dual-computer cooperation and multi-computer cooperation.

Flexible Production

With fast switching of various functional scenarios,flexible production can be realized by human-machine cooperation,

dual-computer cooperation and multi-computer cooperation.

Hot Searches