- Product Details

- {{item.text}}

Quick Details

-

Power:

-

500W-600W

-

Dimension(L*W*H):

-

W2100x H1300 x D1300mm

-

Weight (KG):

-

300

-

After-sales Service Provided:

-

Engineers

-

Application:

-

Powder Coating Work

-

Product name:

-

Paint Coating System

-

Usage:

-

Powder Coating Workpieces

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Keywords:

-

Powder Coating Line

-

Name:

-

Automatic Spray Painting

-

Color:

-

Customized Colors

-

Equipment Name:

-

Spray Painting Equipment

-

Control System:

-

Auto

Quick Details

-

Machine Type:

-

Powder supply center, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Coating Equipment, Other

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

380V

-

Power:

-

500W-600W

-

Dimension(L*W*H):

-

W2100x H1300 x D1300mm

-

Weight (KG):

-

300

-

After-sales Service Provided:

-

Engineers

-

Application:

-

Powder Coating Work

-

Product name:

-

Paint Coating System

-

Usage:

-

Powder Coating Workpieces

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Keywords:

-

Powder Coating Line

-

Name:

-

Automatic Spray Painting

-

Color:

-

Customized Colors

-

Equipment Name:

-

Spray Painting Equipment

-

Control System:

-

Auto

Products Description

|

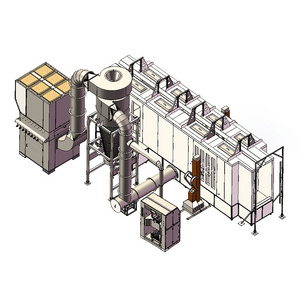

DY-C01

Powder Supply Center

The powder center include: powder supply room and chamber body, exhaust recovery chamber body, exhaust fan, filter element recovery, powder supply pump,

powder supply bucket, powder bucket vibration platform, electric control system and other components. |

|

|

|

|

|

|

|

|

|

|

|

Voltage

|

500v/600v

|

|

|

Powder consumption

|

Max 550g/min

|

|

|

Frequency

|

50~60Hz

|

|

|

Max Output Current

|

200 μA

|

|

|

Output Voltage

|

0-100kv

|

|

|

Input Air pressure

|

0.3-0.6Mpa

|

|

|

Polarity

|

Negative

|

|

|

Gun weight

|

480g

|

|

|

Length of Gun Cable

|

4m

|

|

Advantage:

1)

PLC control system with touch screen interface

2) Powder fluidization is smoother

2) Powder fluidization is smoother

3)

There is alarm system when no powder in the powder tank,the alarm will remind you add powder

4) Automatic powder cleaning through devices and pipelines.

5) Greatly reduce the labor intensity of the operators during the cleaning process and the impact of dust on the health of the operators

4) Automatic powder cleaning through devices and pipelines.

5) Greatly reduce the labor intensity of the operators during the cleaning process and the impact of dust on the health of the operators

How does powder feed center work?

Put the powder hopper full with powder in the powder supply room, and on the powder hopper vibration platform, and then access the air for the fluidization of powder. Vibration platform will vibrate at intervals. Powder particles generated in the process of fluidization goes through the rear ventilation pipe so that powder doesn’t spill. In the process of powder gun working, the powder pump station will be decreased, so that the suction tube is inserted into fluidizing powder.

Control the pump station decreasing by powder detecting sensor, so that the powder suction tube keep been inserted into the sufficient fluidization powders. With powder level declining, when the powder level reaches the lower limit, the powder center of the electronic control system will issue audible alarm and on the touch screen with character note. Remind the operator low powder level alarm, and he or she needs to add powder. In the cleaning process, lower the pump platform down to the powder cleaning level. Open and clear the powder. Powder center automatically blow backs the powder gun hoses of both sides alternately.

If change the color, rise the pump station to higher point for the powder hopper can be easily removed, and then carried the powder hopper with required color in.

Put the powder hopper full with powder in the powder supply room, and on the powder hopper vibration platform, and then access the air for the fluidization of powder. Vibration platform will vibrate at intervals. Powder particles generated in the process of fluidization goes through the rear ventilation pipe so that powder doesn’t spill. In the process of powder gun working, the powder pump station will be decreased, so that the suction tube is inserted into fluidizing powder.

Control the pump station decreasing by powder detecting sensor, so that the powder suction tube keep been inserted into the sufficient fluidization powders. With powder level declining, when the powder level reaches the lower limit, the powder center of the electronic control system will issue audible alarm and on the touch screen with character note. Remind the operator low powder level alarm, and he or she needs to add powder. In the cleaning process, lower the pump platform down to the powder cleaning level. Open and clear the powder. Powder center automatically blow backs the powder gun hoses of both sides alternately.

If change the color, rise the pump station to higher point for the powder hopper can be easily removed, and then carried the powder hopper with required color in.

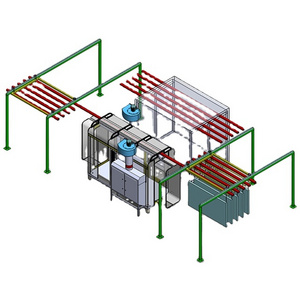

Corollary Equipment

Widely used

Hot Searches