- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 50HZ

-

Weight (KG):

-

5000

-

Billet length:

-

6 meters

-

Billet diameter:

-

70-406mm

-

billet diameter:

-

3-16 inch

-

casting method:

-

hot top casting, air slipper casting, oil slipper casting

-

Application:

-

Foundry Industry

-

Usage:

-

Round Bar

-

Type:

-

Horizontal Continuous Casiting Machine

-

Technology:

-

Automatic Mold Adjustment

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Machine Type:

-

casting machine, die casting machine

-

Brand Name:

-

Alumall

-

Voltage:

-

380V, 50HZ

-

Weight (KG):

-

5000

-

Billet length:

-

6 meters

-

Billet diameter:

-

70-406mm

-

billet diameter:

-

3-16 inch

-

casting method:

-

hot top casting, air slipper casting, oil slipper casting

-

Application:

-

Foundry Industry

-

Usage:

-

Round Bar

-

Type:

-

Horizontal Continuous Casiting Machine

-

Technology:

-

Automatic Mold Adjustment

Product Description

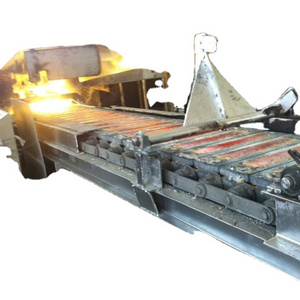

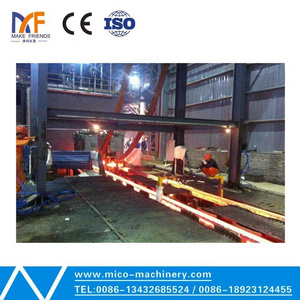

4 Inch Automatic Aluminum Billet Continuous Casting Machine

There are 2 types, hydraulic type and charger type.

The maximum quantity of billet on the hot top is up to 130 Pcs.

Hot top system use wire rope and hydraulic system which is more convenient comparing with the traditional type.

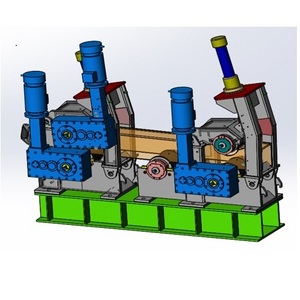

Hot top table main components include: billet casting mould, pulling machine, well, etc.

Hot top billet casting machine spare parts like: distributor tray, retain cup, graphite ring, rubber seal, etc.

Features

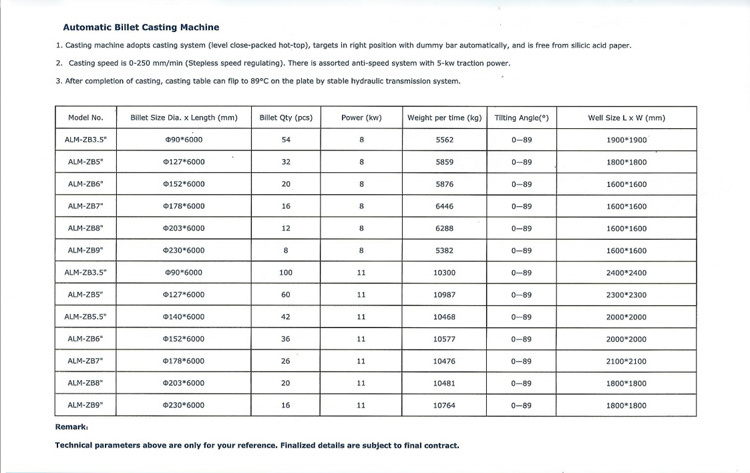

1.Casting machine adopts casting system (level close-packed hot-top), targets in right position with dummy bar automatically, and is free from silicic acid paper.

2. Casting speed is 0-250 mm/min (Stepless speed regulating). There is assorted anti-speed system with 5-kw traction power.

3. After completion of casting, casting table can flip to 89°C on the plate by stable hydraulic transmission system.

The maximum quantity of billet on the hot top is up to 130 Pcs.

Hot top system use wire rope and hydraulic system which is more convenient comparing with the traditional type.

Hot top table main components include: billet casting mould, pulling machine, well, etc.

Hot top billet casting machine spare parts like: distributor tray, retain cup, graphite ring, rubber seal, etc.

Features

1.Casting machine adopts casting system (level close-packed hot-top), targets in right position with dummy bar automatically, and is free from silicic acid paper.

2. Casting speed is 0-250 mm/min (Stepless speed regulating). There is assorted anti-speed system with 5-kw traction power.

3. After completion of casting, casting table can flip to 89°C on the plate by stable hydraulic transmission system.

Specification

Details Images

Hot Searches