- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

China

-

Brand Name:

-

Forest Paint

-

Model Number:

-

FP-PP

-

Product Name:

-

Polyurethane paint

-

Appearance:

-

Hard Film

-

Color:

-

Customized

-

Type:

-

Two Components

-

Material:

-

Polyurethane resin

-

Feature:

-

Weather Resistance

-

Density:

-

1.25 g/L( after mixing)

-

Application:

-

Streel structure, machine, marine, tank

-

Gloss:

-

Matt\satin\Glossy\High Glossy

-

Keywords:

-

Polyurethane topcoat

Quick Details

-

CAS No.:

-

9003-01-4

-

Other Names:

-

Polyurethane anticorrosion coating

-

MF:

-

Mixture

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

China

-

Brand Name:

-

Forest Paint

-

Model Number:

-

FP-PP

-

Product Name:

-

Polyurethane paint

-

Appearance:

-

Hard Film

-

Color:

-

Customized

-

Type:

-

Two Components

-

Material:

-

Polyurethane resin

-

Feature:

-

Weather Resistance

-

Density:

-

1.25 g/L( after mixing)

-

Application:

-

Streel structure, machine, marine, tank

-

Gloss:

-

Matt\satin\Glossy\High Glossy

-

Keywords:

-

Polyurethane topcoat

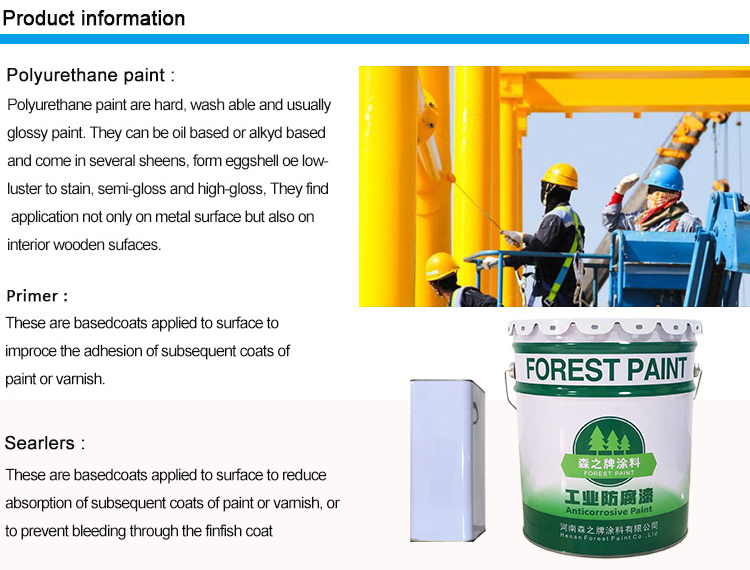

Polyurethane , epoxy primer for corrosion resistance and anti-fouling on carbon steel

Polyurethane topcoat is developed into an anti - corrosive paint based on hydroxyl resin, various colors of pigments, additives and organic solvents to form the paint base, and aliphatic polyisocyanate as curing agent. Mix according to the specified ratio when in use, and use up within the specified time after fully mixing.A two-component heavy-duty anti-corrosion coating prepared by advanced technology by adding epoxy resin with excellent anti-corrosion performance, special additives, high-quality pigments and fillers, additives, etc

| Viscosity (Stormer viscometer), KU | ≥60 |

| Fineness, um | ≤40 |

| Gloss | High |

| Solids content,% | 55-65 |

| Dry film thickness, um | 60 |

| Drying time (25℃), H | Surface dry2h, hard dry≤24h |

| Hardness, Class | ≥0.5 |

| Adhesion (zoned method), class | ≤1 |

| Impact strength, kg, CM | ≥50 |

| Flexibility, mm | ≤1 |

| Alkali resistance | 48 hrs |

| Water resistance | 48 hrs |

Product Features:

. film is tough and fullness, high gloss, good decorative performance

. Excellent weather resistance, light color retention

. Excellent smoke resistance, water resistance, oil resistance, resistance to impact and abrasion

. Good physical and mechanical properties

Polyurethane topcoat P ackaging and ratio:

Primer and topcoat are two component packaging, Group A: paint 20kg, Group B: curing agent 4 kg, 5 to 1 (weight ratio) mixing . Use after curing for 20 minutes. it is recommended that the number of coating channels: a primer, topcoat two to three, depending on the need for coating thickness.

1) Preparations Metal substrate must be polished and sandblasted to remove surface rust and no dust to ensure good adhesion of paint film. Metal surface treatment up to SA2.5 grade standard leakage of metal gloss is more conducive to construction coating.

2) Primer Primer is the foundation of anticorrosive coating. Primer has excellent anticorrosion and adhesion. It is recommended to use spraying method to spray 1-2 layers to ensure anticorrosive performance.

3) Intermediate Paint The intermediate paint has excellent adhesion, mainly links the primer and topcoat, increases the film thickness, enhances the anticorrosion effect, the commonly used intermediate paint is the thick slurry epoxy intermediate paint, Epoxy mio barrior paint and so on, recommends the spraying way construction.

4) Topcoat Topcoat has protective bottom coating, excellent decoration, topcoat coating requires high surface effect, spray construction paint film should be smooth and straight.