- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

1500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

bamboo uv roller coater machine

-

Coating width:

-

1300 mm

-

Feeding Speed:

-

5-30 m/min

-

Feeding power:

-

1.5kw

-

Coating roller power:

-

1.5kw x 2

-

Smooth roller power:

-

0.75kw x 2

-

Heating power:

-

3 kw

-

Total motor power:

-

9 kw

-

Overall dimensions:

-

1600 x 2150 x 1300 mm

Quick Details

-

Machine Type:

-

Automatic roller coating machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GYD

-

Voltage:

-

380V

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

1500

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

bamboo uv roller coater machine

-

Coating width:

-

1300 mm

-

Feeding Speed:

-

5-30 m/min

-

Feeding power:

-

1.5kw

-

Coating roller power:

-

1.5kw x 2

-

Smooth roller power:

-

0.75kw x 2

-

Heating power:

-

3 kw

-

Total motor power:

-

9 kw

-

Overall dimensions:

-

1600 x 2150 x 1300 mm

Product Description

Related Products

Suitable for flat panel of calsium silicate/fiber cement, glass magnesium plate.

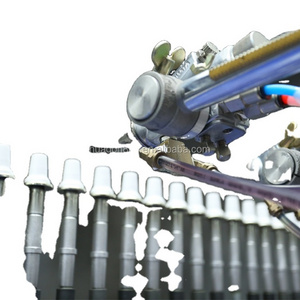

This machine is used in filling the wood holes and fiber holes, which could filling kinds of solid wood and veneer surface holes

that result from hollow, or holes which result of not enough density of fiber. So it makes the board’s surface smooth and remove

redundant paint for recycle to using.

The coated boards that processed by this machine can carry out precision sanding after primer coating to improve the smoothness of

the board surface and the adhesion between board and paint coating.

that result from hollow, or holes which result of not enough density of fiber. So it makes the board’s surface smooth and remove

redundant paint for recycle to using.

The coated boards that processed by this machine can carry out precision sanding after primer coating to improve the smoothness of

the board surface and the adhesion between board and paint coating.

|

Model

|

GYGT600

|

GYGT1000

|

GYGT1300

|

|

Coating Width

|

600mm

|

1000mm

|

1300mm

|

|

Feeding speed

|

5-30 m/min

|

5-30 m/min

|

5-30 m/min

|

|

Feeding power

|

0.75kw

|

0.75kw

|

1.5kw

|

|

Coating roller power

|

0.75kw x 2

|

0.75kw x 2

|

1.5kw x 2

|

|

Smooth roller power

|

0.37kw x 2

|

0.37kw x 2

|

0.75kw x 2

|

|

Heating power

|

3 kw

|

3 kw

|

3 kw

|

|

Total motor power

|

6 kw

|

6 kw

|

9 kw

|

|

Overall dimensions

|

1600x1350x1300mm

|

1600x1750x1300mm

|

1600x2150x1300mm

|

|

Weight

|

1100kg

|

1400kg

|

1400kg

|

High precision production for the high-quality standard.

Introduce international machine design philosophy, stable structure, noiseless,dynamic equilibrium mechanics, no color difference

Introduce international machine design philosophy, stable structure, noiseless,dynamic equilibrium mechanics, no color difference

CNC casting

Machine structure

Rubber roller

Conveyor

Smart electric box

Touch screen control

Bearing protection

A

utomatic adjust working thickness

Motors

|

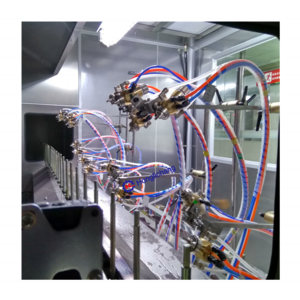

Coating system

|

The coating roller and doctor roller are precisely controlled by independent inverter motors and reducers to make the stable coating processing.

|

|

Lifting system

|

The lifting system is dovetail design, precisely automatic goes up and down.

|

|

Paint system

|

All paint recycle channels and paint heating barrels are using qualified stainless steel.

|

|

Feeding system

|

The whole welding design make the strong structure, the conveyor belt is high quality PVC belt

|

|

Electrical system

|

Delta converters, CHINT low voltage electrical components

|

|

Easy-maintenance

|

The casting design considered the rollers' exchange, the roller changing is fast and easy.

|

Roller Coating Effect

It's available to the base\surface paint coating for the furniture\flooring\cabinet\walling\decorative boards, which

different materials as wood\MDF\plastic\metal\glass\CaSi and so on.

It's available to the base\surface paint coating for the furniture\flooring\cabinet\walling\decorative boards, which

different materials as wood\MDF\plastic\metal\glass\CaSi and so on.

Wood veneer pore open

Color stain

Clear primer

Solid color

Primer

Shaped products

Application industries

Wall panels

Furniture

Wardrobe

The Roller Coating Machine Area

Standard BOM, every production process standardization, every inspection step standardization.

Standard BOM, every production process standardization, every inspection step standardization.

Our Advantages

Our services & advantage: ● Support customized service, OEM service,small batch purchase,Fast reaction. ● High quality and

guarantee,Using quality environmental protection material. ● Customer always first,We pay special attention to product quality and

delivery.Fast response within one working day. ● Meet customer needs,Competitive price with high quality. ● Professional

production team can provide you with logo, color, pattern custom. ● Can meet the individual needs of customers.products prices are

negotiable. Looking forward to your inquiry.

guarantee,Using quality environmental protection material. ● Customer always first,We pay special attention to product quality and

delivery.Fast response within one working day. ● Meet customer needs,Competitive price with high quality. ● Professional

production team can provide you with logo, color, pattern custom. ● Can meet the individual needs of customers.products prices are

negotiable. Looking forward to your inquiry.

Customer Photos

Hot Searches