- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

XCJ

-

Model Number:

-

MGEHL External Grooving Holder

-

Product name:

-

MGEHL External Grooving Holder

-

Material:

-

60Si2Mo

-

Application:

-

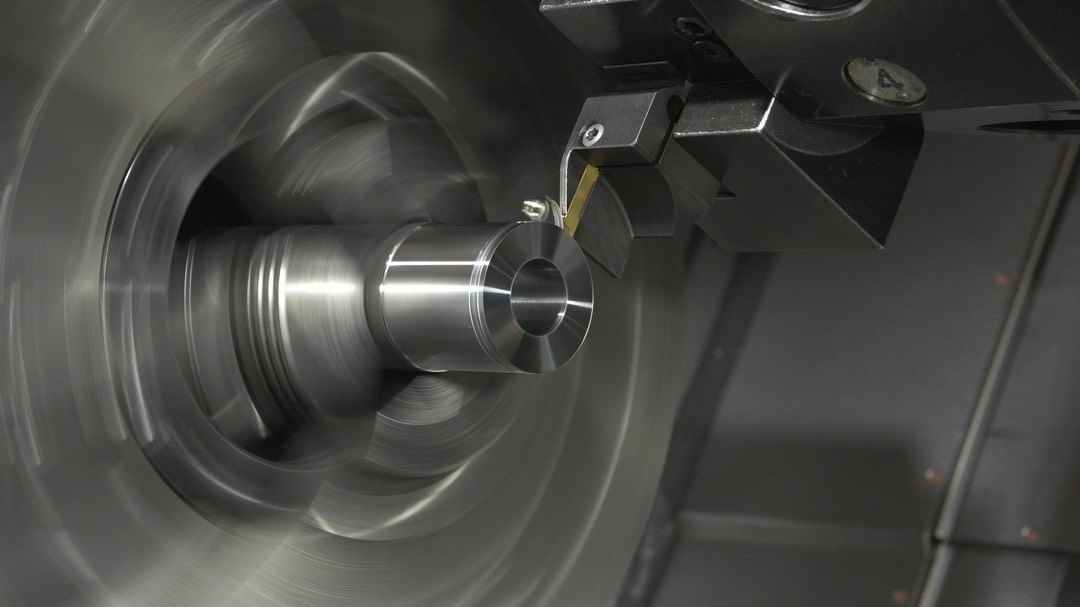

CNC Lathe

-

Workpiece:

-

Steel\ Stainless\ Cast Iron

-

Type:

-

Grooving Cutting Turning tool

-

Color:

-

Silver White

-

Advantage:

-

High Efficiency

-

TRANSPORT:

-

TNT\DHL\ Fedex\ EMS\ UPS

Quick Details

-

Use:

-

External Turning Tool

-

Hardness:

-

HRC40-60

-

Coating:

-

PVD CVD

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

XCJ

-

Model Number:

-

MGEHL External Grooving Holder

-

Product name:

-

MGEHL External Grooving Holder

-

Material:

-

60Si2Mo

-

Application:

-

CNC Lathe

-

Workpiece:

-

Steel\ Stainless\ Cast Iron

-

Type:

-

Grooving Cutting Turning tool

-

Color:

-

Silver White

-

Advantage:

-

High Efficiency

-

TRANSPORT:

-

TNT\DHL\ Fedex\ EMS\ UPS

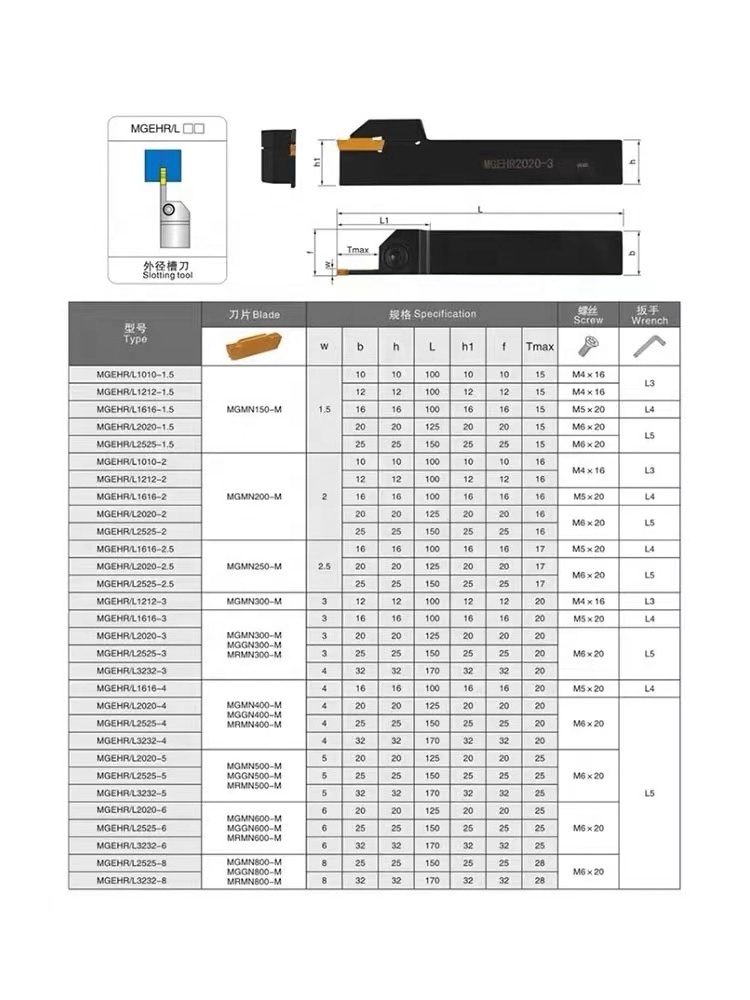

MGEHL

Grooving External Cutting Tool Holder

Using high-strength alloy spring steel 60Si2Mn, more stable, more shock-resistant, more wear-resistant, stable long-term processing dimensions, extended insert life, and high processing accuracy。

|

product name

|

Grooving External Cutting tool holder

|

|

Material

|

60Si2mn High quality spring steel

|

|

Hardness

|

HRC48-52°

|

|

Processing materials

|

stable cutting of steel parts, stainless steel, castings, etc

|

|

application

|

CNC lathe machining

|

|

MOQ Quantity

|

1pc

|

|

Package

|

1pc in one box

|

About the product

Free forging process

Using the impact force, the metal is freely deformed in all directions between the upper and lower drilling surfaces, eliminating defects such as shrinkage, shrinkage and porosity, and making the tool blank have higher mechanical properties.

1060 degree high temperature quenching

High temperature heat treatment process, choose water, oil and other materials for rapid cooling at low temperature and tempering at high temperature, which greatly improves the strength, hardness, wear resistance, fatigue strength and toughness of the tool.The surface is bright.

High temperature heat treatment process, choose water, oil and other materials for rapid cooling at low temperature and tempering at high temperature, which greatly improves the strength, hardness, wear resistance, fatigue strength and toughness of the tool.The surface is bright.

Congratulations! You have found us --- your reliable carbide tool factory!

quality assurance:

1. We are equipped with world advanced 5-axis CNC production lines from Germany and Australia.

2. All original rods are carefully selected and processed by advanced testing equipment.

3. Extra coating powers the tool for higher heat resistance and longer tool life.

We offer a wide range of high-value solid carbide end mills, as well as different types of tool holders, saw blades, turning inserts, milling inserts, turning tools, machine tool accessories, etc.

We provide milling cutters with different flute diameters from 0.03mm-32mm and total lengths from 35mm-200mm for your market winner. HRC45/55/60/65, 1-6 edge cutting for your choice.

Our service:

1. Free sample support (free samples but pay the shipping fee, the lowest shipping fee is for you to choose, and the shipping fee will be refunded after you place an order for trial)

2. For distributors, we can put your brand label on the knives and plastic box

3. You can choose AlTiN, TiAlN, TiSiN, Tin, DLC (Diamond-Like Coating), Nano, and beat the competition!

4. Product diversity, we can help you buy any CNC related products, and guarantee the best price.

5. Become our VIP customer, there will be professional customer service and technical personnel to communicate with you to solve various problems that arise during your processing.

Why Choose Us

Chengdu Xin'chuangjie CNC Tool Co., Ltd.

is a professional enterprise specializing in the production of high-quality carbidetools, manufacturing and sales of high-quality carbide tools.The main equipment comes from Germany, the United Statesand Switzerland.Equipment industry, automobilemanufacturing industry, petroleum industry, medical machineryand other industries provide complete cutting tool solutions.The company's main business is: carbide milling cutters,carbide drills.carbide reamers,non-standard toolcustomization, taps,CNC blades,CNC tool holders. CNC toolsand machine tool accessories,etc.

In addition to

a broad line of standard cutting tools,

Xin'chuangjie

boasts a full complement of custom tooling capabilities including an experienced team of application specialists and custom tooling designers, who provide our customers with diverse engineering capabilities. This expertise has grown organically from a combined 10-plus years of design experience. The creation of unique customer solutions can provide significant value the form of performance improvement and profitability improvement.

Passivation equipment

quality inspection

Laser marking

Non-standard milling cutter warehouse

CNC blade warehouse

CNC cutter bar warehouse

Vietnam Exhibition

Cambodia Exhibition

Thailand Exhibition

CERTIFICATE

SALES AND SERVICE NETWORK

TRANSPORT

FAQ

Q: Are you a manufacturer? Do you have a factory?

A:

We are professional manufacturers with more than 15 years of experience in the field of cutting tools.5 year of tungsten carbide export business. We have three sales stores in China, can provide you with one-stop shopping, meanwhile we have an excellent and professional sales team, we have strict desire on the quality of the carbide tools.

Q: Delivery time?

A: Usually the exchange time is 3-5 days after receiving the advance payment. For customized products, 15-20 days after receiving the advance payment.

Q:

How long can I expect to get the sample?

A:

fter you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 workdays.

Q:

what can you buy from us?

A:

Carbide End Mills, Carbide Drills, Carbide Inserts, Carbide Thread Mills, Carbide Custom Tools, CNC Tool holders, CNC Cutter Heads, CNC Tools, etc.

.

Q: What's your delivery method?

A: Express, DHL, TNT, FEDEX, EMS, air and sea can be provided according to your requirements.

Q: Do you offer OEM?

A: Yes, we do.

Q: Do you produce special carbide tools?

A: We can, we can customize it according to your drawings and samples.

Q: What are your payment terms?

A: T/T30% as a down payment and 70% delivery time. Before you pay, we will show you pictures of the product and packaging.

Hot Searches