- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Runxiang

-

Dimension(L*W*H):

-

1.1*1.2*2.1m

-

Product name:

-

Brequitte Making Machine

-

Raw material:

-

Charcoal Powder

-

Briquette shape:

-

Square

-

Power:

-

22kw

-

Key words:

-

Recycle Environmental Protection Equipment

-

Advantage:

-

Low Consumption High Efficiency

-

Function:

-

Charcoal Briquette Shaping Machine

-

Suitable for:

-

COCONUT COAL

Quick Details

-

Weight (KG):

-

750

-

Production Capacity:

-

90%, 200-350kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Runxiang

-

Dimension(L*W*H):

-

1.1*1.2*2.1m

-

Product name:

-

Brequitte Making Machine

-

Raw material:

-

Charcoal Powder

-

Briquette shape:

-

Square

-

Power:

-

22kw

-

Key words:

-

Recycle Environmental Protection Equipment

-

Advantage:

-

Low Consumption High Efficiency

-

Function:

-

Charcoal Briquette Shaping Machine

-

Suitable for:

-

COCONUT COAL

Product Description

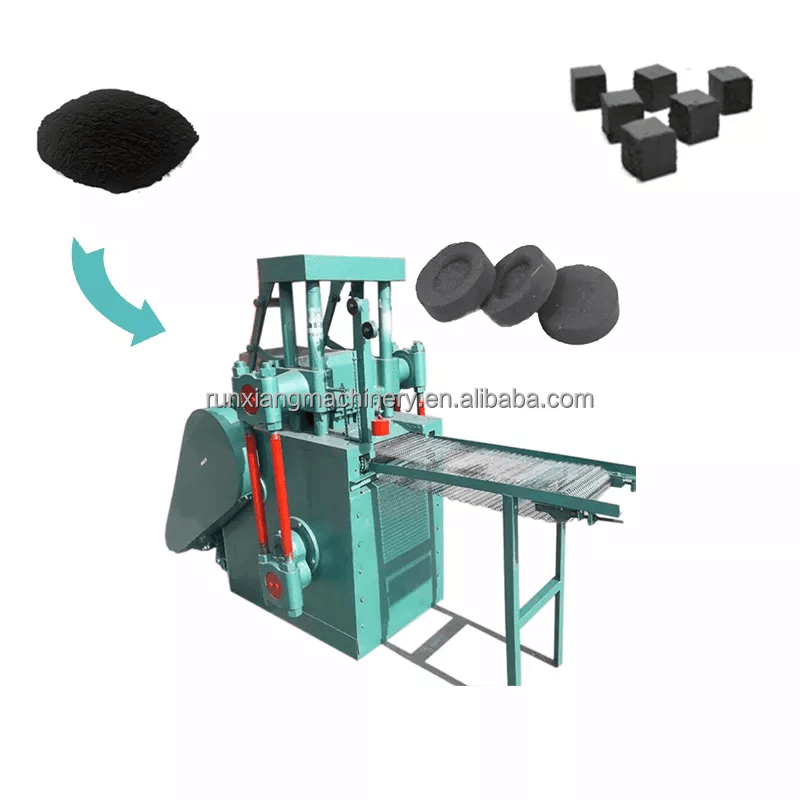

Introduction:

Briquetting machine is an essential equipment for producing high-quality briquettes. It is used to compress a wide range of raw materials into uniform-sized briquettes, which can be used as fuel in industrial boilers, biomass power plants, and domestic cooking. The raw materials of briquetting machines can be biomass materials or agriculture waste, such as sawdust, rice husk, straw, corn stalks, peanut shells, cotton stalks, and other crop residues. This article will introduce the raw materials of the briquetting machine, the applicable industries, the advantages of charcoal making machine, the characteristics of smokeless charcoal machine, future development, and benefits to the environment and society.

Detailed Images

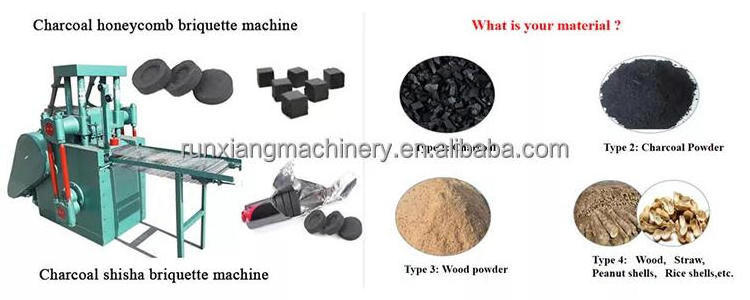

Raw materials of Briquetting machine:

The raw materials used in briquetting machines can be divided into two categories, namely, biomass materials and agriculture waste. Biomass materials include sawdust, coconut shell, palm shell, bamboo, peanut shell, wheat straw, etc. Agriculture waste includes corn stalks, cotton stalks, rice straw, sugar cane bagasse, etc.

The choice of raw materials depends on factors such as geographical location, availability, and cost. For example, sawdust is commonly used as a raw material in briquetting machines because it is cheap and readily available. On the other hand, coconut shells and bamboo are preferred in areas where they are abundant.

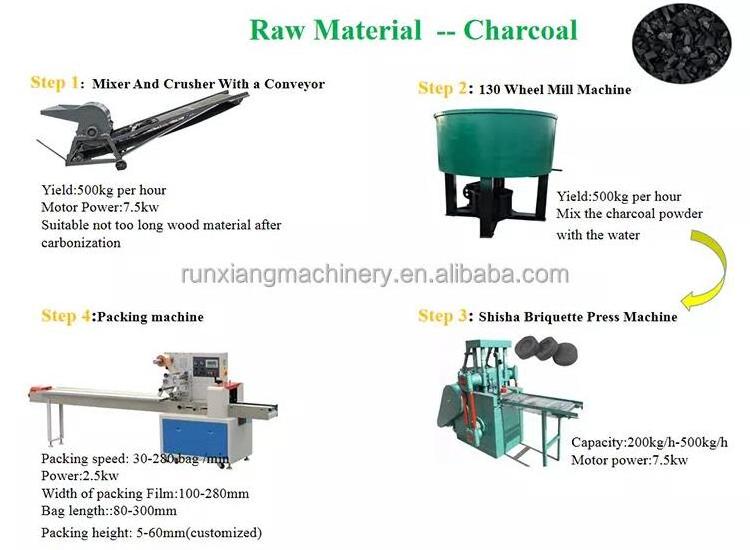

Procession about the machine line

1. Raw material is wooden

2. Raw material is Charcoal

3. Raw material is Charcoal Power

Industries that utilize Briquetting Machine:

The industries that use briquetting machines are diverse, with the most common being the charcoal, biomass, and energy industries. The following table shows the various industries that use briquetting machines:

Industry | Sector | Biomass Materials | Agriculture Waste

Charcoal | Cooking and heating | Sawdust, coconut shell, palm shell | Cotton stalks, corn stalks, rice straw

Biomass | Power generation, industrial boilers | Wood, sawdust, straw, grass | Sugar cane bagasse, corn stalks, cotton stalks

Energy | Gasification, pyrolysis | Wood, straw, grass, sawdust | Corn stalks, cotton stalks, rice straw, sugar cane bagasse

Manufacture Specification

|

Model

|

Capacity

|

weight

|

Size(m)

|

|

Charcoal dust briquette machine

|

3000pcs/h

|

2200kg

|

1.1*1.2*2.1m

|

Product description:

Future Development of Coal Rod Briquette Making Machine:

1. Automation: The machines are expected to become more automated, with the use of advanced technologies such as artificial intelligence and machine learning.

2. Optimization of the process: The machines are expected to become more optimized to improve efficiency and reduce energy consumption.

3. Adaptability: The machines are expected to become more adaptable to a wider range of raw materials, making them more versatile.

4. Scalability: The machines are expected to become more scalable, with the ability to produce more briquettes in a shorter period.

5. Integration: The machines are expected to be integrated with other machines and equipment to form a complete briquetting production line.

Best Selling

Company Introduction

Hot Searches