- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

>99%

-

Voltage:

-

380V 50HZ(Can be customized)

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

CHENGXIANG

-

Dimension(L*W*H):

-

2.41*1.06*1.8m

-

Weight:

-

500 KG

-

Touch screen:

-

Siemens(optional)

-

PLC:

-

Siemens(optional)

-

Inverter:

-

Mitsubishi

-

Main motor:

-

ABB

-

low-voltage apparatus:

-

Schneider

-

Common speed:

-

30-60b/m

-

Material:

-

316L+304 Stainless steel

-

Certification:

-

CE/GMP/ISO/TUV

-

Filling pump:

-

Piston pump

-

Advantage:

-

Can be customized

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Glass, Metal, Plastic

-

Filling Material:

-

Water, Oil, Juice

-

Filling Accuracy:

-

>99%

-

Voltage:

-

380V 50HZ(Can be customized)

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

CHENGXIANG

-

Dimension(L*W*H):

-

2.41*1.06*1.8m

-

Weight:

-

500 KG

-

Touch screen:

-

Siemens(optional)

-

PLC:

-

Siemens(optional)

-

Inverter:

-

Mitsubishi

-

Main motor:

-

ABB

-

low-voltage apparatus:

-

Schneider

-

Common speed:

-

30-60b/m

-

Material:

-

316L+304 Stainless steel

-

Certification:

-

CE/GMP/ISO/TUV

-

Filling pump:

-

Piston pump

-

Advantage:

-

Can be customized

Model No:CX-GFT Automatic filling machine

No.1 CX-GP Bottle feeder turntable

---SUS 304 stainless steel

---Suitable for plastic bottle and glass bottle

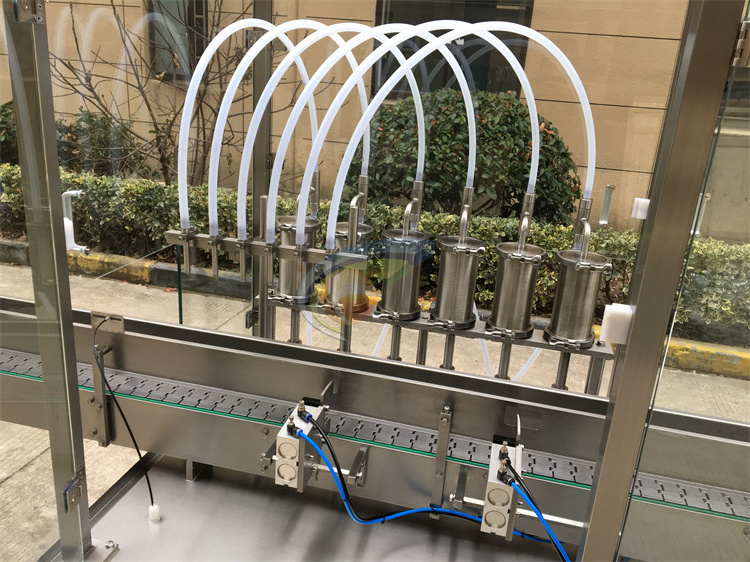

No.2 CX-GFT Automatic 6 nozzles filling capping machine

---SUS304 stainless steel for machine frame

---Filling and capping in one machine

SUS316L stainless steel filling nozzle and piston pump

---5-10mins do the piston pump cleaning,very easy

Filling-covering-capping 3 in 1 machine

---For different bottle size,changing replacement parts is ok

Caping head for ropp cap

Siemens HMI+Servo motor system

---adjust the filling volume on touch screen,less than 1 min

Finished samples

No.3 CX-LT Automatic vertical labeling machine

---With servo motor controlled

---With Germany Leuze sensor detect the labels

No.4 CX-SP Bottle collecting table

---SUS304 stainless steel

Characteristic

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

2.Including feeder turntable,effective cost/space saving(optional)

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5.Siemens Touch screen/PLC(optional)

6.No bottle no filling/plugging/capping

Main Technical Parameters

|

Applied Bottle |

20-200 ml |

|

Productive Capacity |

10-50pcs/min 4filling nozzles 50-60pcs/min 6 filling nozzles 60-80pcs/min 8 filling nozzles 80-100pcs/min 10 fillling nozzles 100-120pcs/min 12 filling nozzles |

|

Filling Tolerance |

0-2% |

|

Qualified Stoppering |

≥99% |

|

Qualified cap putting |

≥99% |

|

Qualified capping |

≥99% |

|

Power Supply |

110/220/380V ,50/60HZ |

|

Power |

1.5KW |

|

Net Weight |

600KG |

|

Dimension |

2500(L)×1000(W)×1700(H)mm |

Famous brand electrical

|

Machine frame |

SUS304 Stainless steel |

|

|

The parts which contact liquid |

SUS316L Stainless steel |

|

|

Main Motor |

ABB |

Switzerland |

|

Inverter |

Japan |

|

|

Air Switch |

Schneider |

France |

|

Contactor |

Schneider |

France |

|

Relay |

Omron |

Japan |

|

OFA |

Autonics |

Korea |

|

Bearing |

IGUS |

Germany |

|

CAM indexer |

Shangdong |

China |

|

Turntable |

Plastic POM |

Japan |

|

Cylinder |

AIRTAC |

Taiwan |

|

Touch screen(optional) |

Siemens |

Germany |

|

PLC(optional) |

Siemens |

Germany |