1. The operator of the asphalt crack sealing machine must be trained.

2. Workers should wear reflective overalls when working on the road.

3. Before starting working, workers should check the oil circuit and pipeline connection to ensure no leakage when the crack

sealing machine is working.

4. Be careful of the high-temperature part of the asphalt crack sealing equipment to avoid burns.

5. When adding the cracking sealing material, pay attention to avoiding the asphalt splash.

6. There should be no water and air when adding heat conduction oil.

7. When operating the road crack sealing machine, please keep an eye on the condition of the furnace and temperature thermometer.

8. If an emergency happens, please turn off the power supply engine in time.

9. Don't put stones and other debris into the oil tank of the hot asphalt crack filler machine.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2400 kg

-

Product name:

-

Crack Joint Sealing Machine

-

After Warranty Service:

-

Video Technical Support

-

Application:

-

Road Crack Filling Repair

-

Usage:

-

Highway

-

Fuel Type:

-

Liquefied gas

-

Function:

-

Asphalt Sealing Equipment

-

After-sales Service Provided:

-

Commissioning

-

Walking Mode:

-

Hand Push

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

IDEAL

-

Dimension(L*W*H):

-

2150*1250*1460mm

-

Weight:

-

2400 kg

-

Product name:

-

Crack Joint Sealing Machine

-

After Warranty Service:

-

Video Technical Support

-

Application:

-

Road Crack Filling Repair

-

Usage:

-

Highway

-

Fuel Type:

-

Liquefied gas

-

Function:

-

Asphalt Sealing Equipment

-

After-sales Service Provided:

-

Commissioning

-

Walking Mode:

-

Hand Push

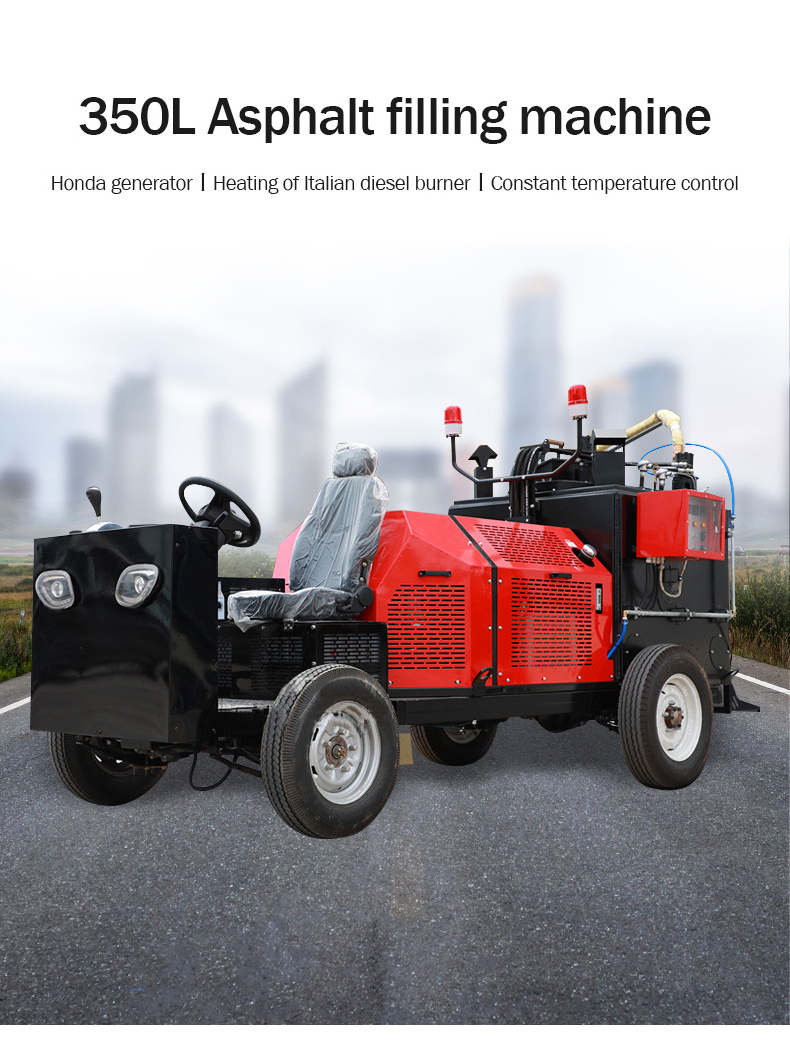

Large Capacity Road Crack Filler Machinery 500l Concrete Crack Filler Machines High Quality Filler for Crack

A

pavement caulking machine

is a new type of asphalt pavement caulking equipment.

The equipment uses a thermal oil circulation to indirectly heat and melt the asphalt to ensure that the asphalt does not scorch, discolor, and paste the barrel.

Hose caulking, manual forward and reverse stirring, uniform mixing, high melting efficiency, electronic ignition mode, automatic heating temperature control, automatic sensor temperature detection, automatic small fire insulation, high-temperature heating molten material, energy saving and time-saving, Ensuring long-term work.

Products Description

|

Model

|

GF-500

|

|

Tank volume

|

500L

|

|

Driving Style

|

Towing / self-propelled walking

|

|

Engine Model

|

YAMMA 3TNV82A-SUN

|

|

Power

|

16.5KW/22.5HP

|

|

Optional

|

Hydraulic travel system

|

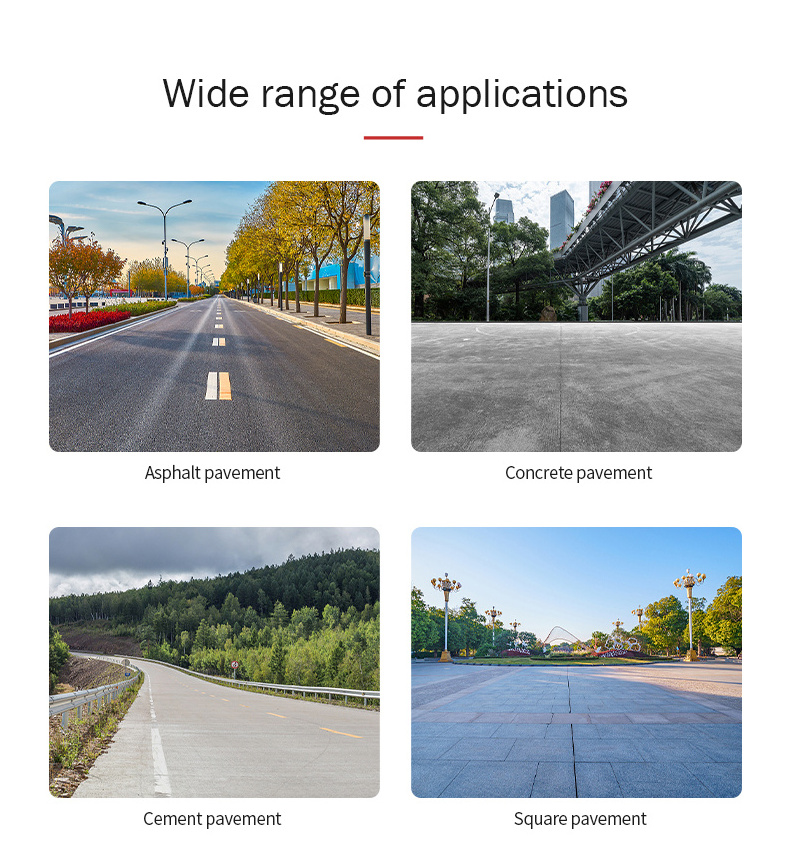

An asphalt crack filler machine is a kind of asphalt crack repair machine that is suitable for filling the cracks in

roads, expressways, asphalt, and concrete pavement of municipal, airports, squares, and industrial parks, as well as filling cracks of complicated and irregular pavement.

As an indispensable road maintenance machine, it is mainly used for preventive maintenance of road surface diseases and in conjunction with road grooving machines and air blowers.

Product Overview

Details Images

Electrically heated discharge pipe: good anti-blocking stainless steel liner and smooth discharge

High thermal conductivity and uniform heating of materials: no deformation in heating and good heat preservation Imported diesel burner as heating source

Strong power: brand engine, strong power, long life, more than 1 time than ordinary products, more than 5 years than ordinary products

Equipped with an Italian imported engine which improves the heat efficiency two or three times and shortens the working time.

Adopt the most advanced technology, which improves the quality of the pouring joint and reduces the cost.

High thermal conductivity and uniform heating of materials: no deformation in heating and good heat preservation Imported diesel burner as heating source

Strong power: brand engine, strong power, long life, more than 1 time than ordinary products, more than 5 years than ordinary products

Equipped with an Italian imported engine which improves the heat efficiency two or three times and shortens the working time.

Adopt the most advanced technology, which improves the quality of the pouring joint and reduces the cost.

Nine Notes for the Operation of the Asphalt Crack Filling Machine:

The machine features

(1) Steam and electricity integrated hybrid power, electric drive technology, low emission, low energy consumption, energy

conservation, and environmental protection.

(2) Advanced intelligent ignition, detection, and temperature control technology.

(3) unique oil jacket hot melt kettle design.

(4) The only thermal cycle heating system design.

(5) Efficient discharge system design.

(6) The whole machine safety low center of gravity design.

(7) Electric stirring.

(8) Anti-blocking design of hot melt kettle

(1) Steam and electricity integrated hybrid power, electric drive technology, low emission, low energy consumption, energy

conservation, and environmental protection.

(2) Advanced intelligent ignition, detection, and temperature control technology.

(3) unique oil jacket hot melt kettle design.

(4) The only thermal cycle heating system design.

(5) Efficient discharge system design.

(6) The whole machine safety low center of gravity design.

(7) Electric stirring.

(8) Anti-blocking design of hot melt kettle

Product packaging

Exporting package

1 unit was packed into an iron frame and then packed with 5 layers of corrugated carton. 4 strips reinforced the carton. the fix package guaranteed the machines were not damaged during transportation

Hot Searches