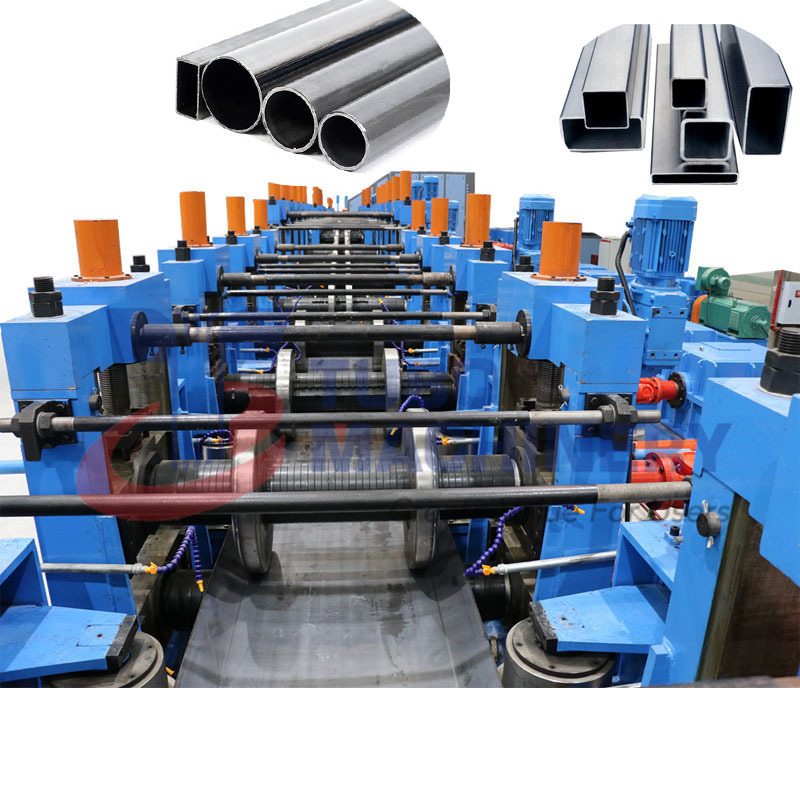

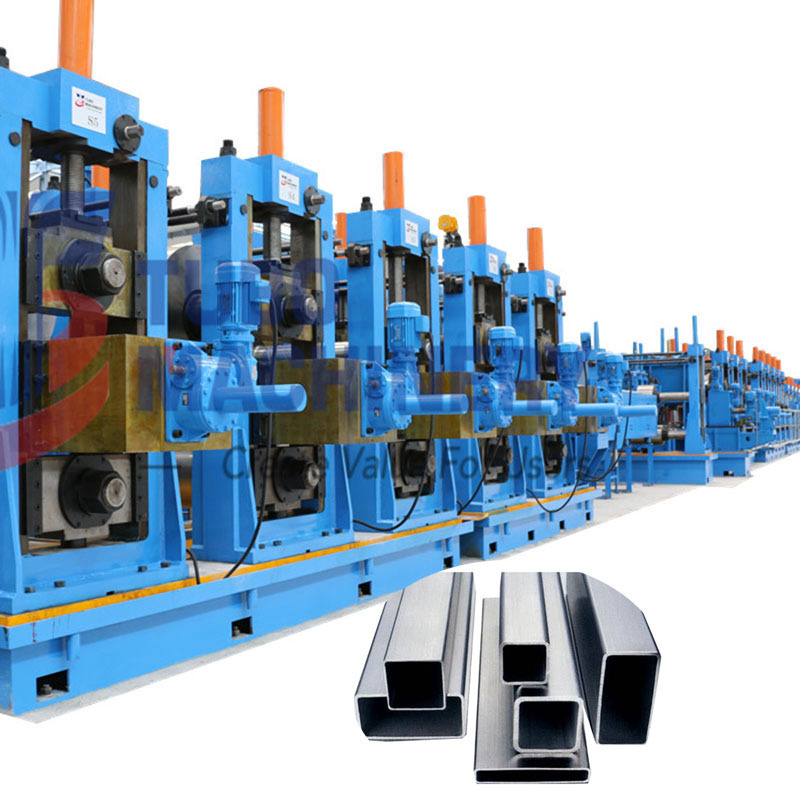

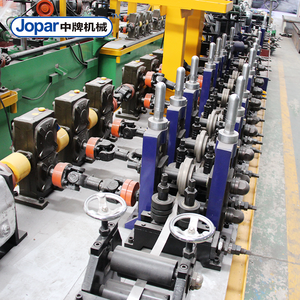

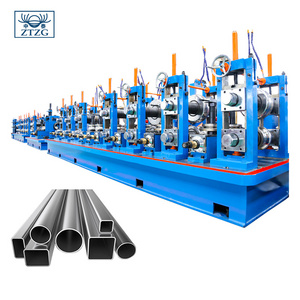

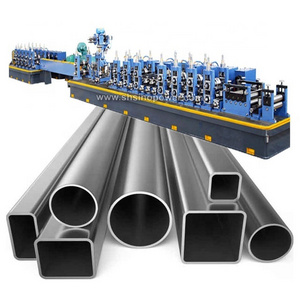

1.1.High Precision

2.High Production efficiency,Line speed can be up to 120m/min

3.High Strength,The machine works stably at a high speed, which improves product quality.

4.High Good product rate, reach to 96.5%

5.Low wastage, Low unit wastage and low production cost.