- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Changhe

-

Voltage:

-

Based on Local

-

Power:

-

57kw

-

Dimension(L*W*H):

-

4000*1800*1800mm

-

Weight (KG):

-

1500

-

Size:

-

customized

-

Heating energy:

-

electric/gas/diesel/LPG

Quick Details

-

Machine Type:

-

powder coating oven, Drying Oven, Curing oven, Coating Equipment

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Changhe

-

Voltage:

-

Based on Local

-

Power:

-

57kw

-

Dimension(L*W*H):

-

4000*1800*1800mm

-

Weight (KG):

-

1500

-

Size:

-

customized

-

Heating energy:

-

electric/gas/diesel/LPG

Products Description

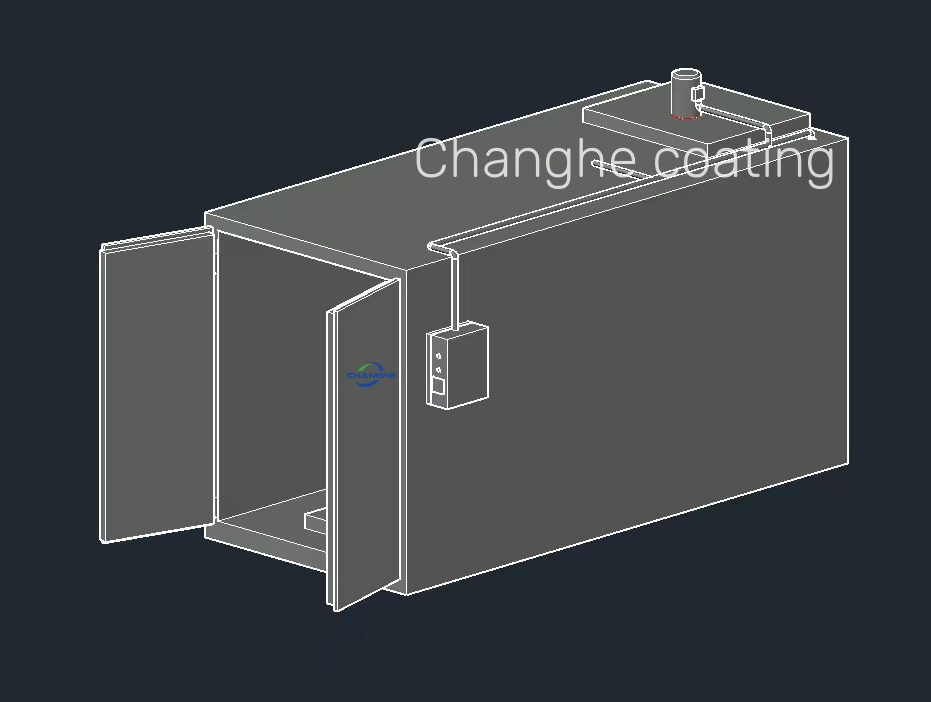

Large Powder Coating Curing Oven For Sale

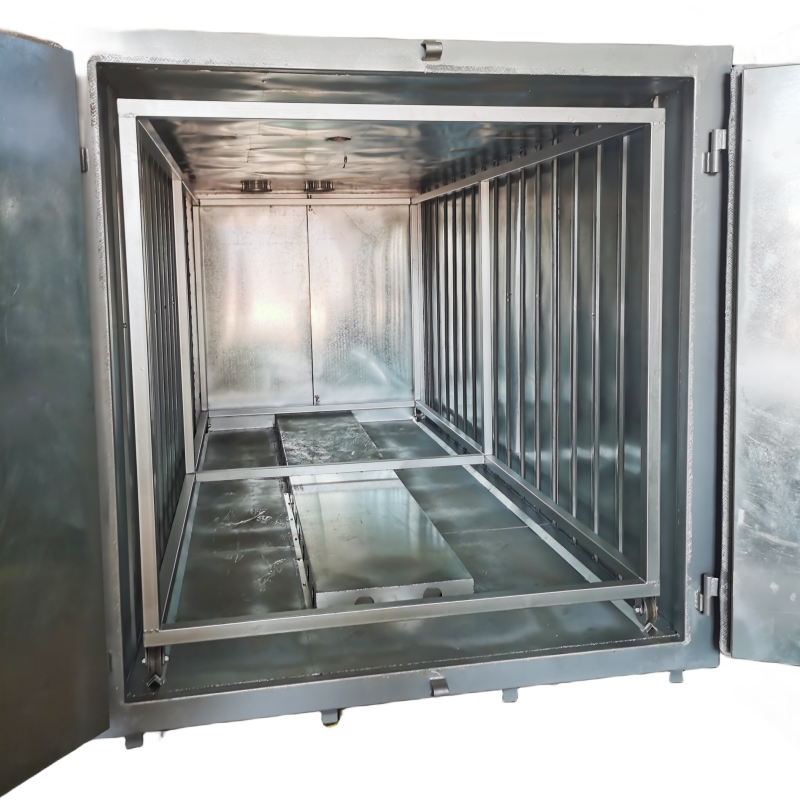

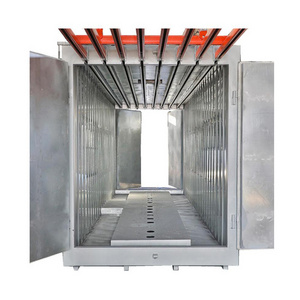

Working Size: Length4000 *Width1800*Height1800 mm

Heating source: could be Electric or Gas / Diesel / LPG

After powder spraying in the spray booth, the workpiece will be placed in the oven for powder curing. The powder is cured by high temperature baking and leveling, and becomes the final coating with different effects.

Heating source: could be Electric or Gas / Diesel / LPG

After powder spraying in the spray booth, the workpiece will be placed in the oven for powder curing. The powder is cured by high temperature baking and leveling, and becomes the final coating with different effects.

Excellent Features

*Suitable for curing powder or paint on the metal surface

*Size can be customized as your workpiece size and needs

*Multi-layer design, galvanized sheet+2 layers of rock wool+skeleton

*Hot air circulate, the temperature is even and consistent.

*Equipped with a trolley, strong bearing capacity, move smoothly

Products Specification

|

Model

|

CH-401818D

|

|

|

Working Size (LxWxH)mm

|

4000 x 1800 x1800

|

|

|

Heating Source

|

Electric/ LPG / GAS / Diesel

|

|

|

Wall Insulation

|

100% new rock wool board with 100 mm thickness

|

|

|

Heating Temperature & Time

|

180° C (15-30min)

|

|

|

Temperature Stability

|

< ± 3-5°C

|

|

|

Voltage/ Frequency

|

415V/380V (50-60hz) , customized as local

|

|

|

Circulation / Air Flow

|

Vertical ,Variable through holes on the walls

|

|

|

Transportation

|

Trolley

|

|

|

The size, color and specifications can be customized all according to your needs.

|

|

|

Details Images

The process of making the oven in our factory

① The outer layer of the oven is formed by folding the edges and corners of galvanized sheet, increasing the firmness.

② Fill in the middle with 2 layers of rock wool, getting a thickness of 100mm.

③ Make the inner layer the oven

④ The door frame is made of bent 2.5 mm iron plate.

③ Make the inner layer the oven

④ The door frame is made of bent 2.5 mm iron plate.

Oven Component

Controller Panel

The user-friendly panel gives you an easy access to set heating temperature, time and working of fan. Once the curing time arrives, the oven will stop heating automatically.

Circulation Fan

Powerful fan circles hot air in the oven chamber, ensures uniform heat distribution with temperature stability less than 3 degree.

100mm Rockwool

The oven utilizes a sandwich panel design. Rock wool insulation of at least 100mm is inserted between galvanized inner wall and color-steel external skins, effectively minimums temperature dropping.

Transportation Trolley

Product hang on the metal shelf, the metal shelf

will be into the oven. By using the trolley, trolley moving across the hall does not contaminate the inside of the oven, which provides high purity

painted elements.

will be into the oven. By using the trolley, trolley moving across the hall does not contaminate the inside of the oven, which provides high purity

painted elements.

Recommend Products

Project Case

Package & Delivery

Hot Searches